Korpus:Korpus neft və qaz quyularının və ya quyularının divarları üçün konstruktiv tutucu rolunu oynayan böyük diametrli borudur. O, quyuya daxil edilir və həm yeraltı layları, həm də quyu quyusunu çökməkdən qorumaq üçün yerində sementlənir. qazma mayesinin sirkulyasiyasına və hasilatın baş verməsinə icazə verin. Polad Korpus Boruları hamar divara və 35.000 psi minimum məhsuldarlığa malikdir.

Boru:Boru qazma işləri başa çatdıqdan sonra xam neft və təbii qazın neft və ya qaz təbəqəsindən səthə nəqli üçün istifadə olunan borudur. Ekstraksiya prosesindən yaranan təzyiqə tab gətirmək üçün hazırlanmışdır. Boru kəmərləri korpusla eyni şəkildə istehsal olunur, istisna olmaqla, boruları qalınlaşdırmaq üçün "qıcıqlanma" kimi tanınan əlavə bir proses tətbiq olunur.

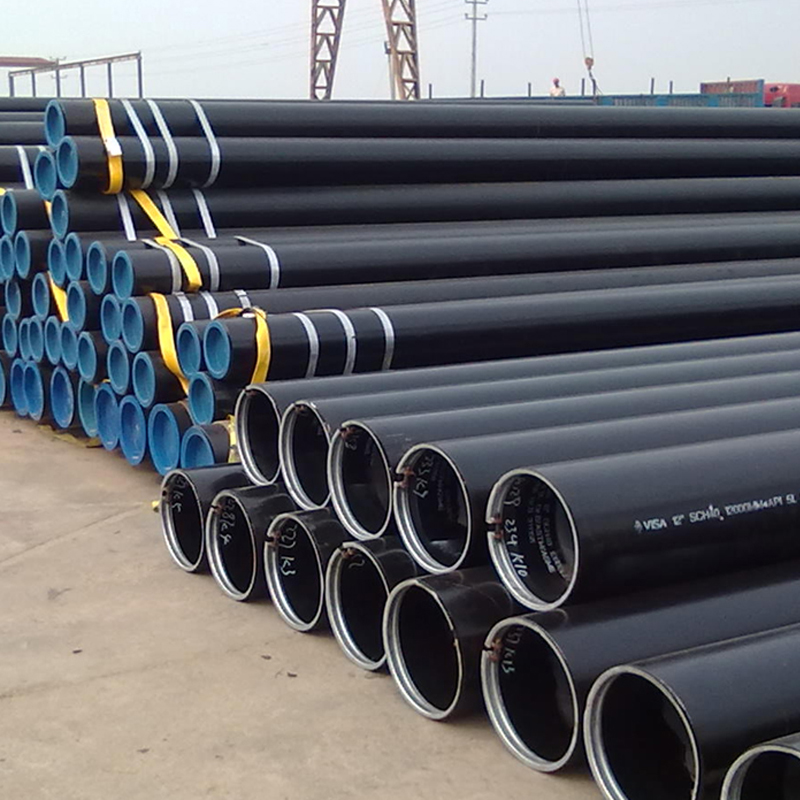

API 5L boru kəmərineft, qaz, su, eləcə də təbii qaz sənayesində nəqlində geniş istifadə olunur. API 5L bütün dünyada Hazırlanmış və Nəşr edilmiş Amerika Neft İnstitutuna istinad edir.

API 5L boru kəməri ilə neft, xam neft, qaz, su və ya təbii qaz yeraltından neft və təbii qaz sənayesi korporasiyasına sonrakı emal istehsalı üçün nəql edilir. Neft və qaz kəmərinə tikişsiz boru və qaynaq boru daxildir və üç düz ucu, yivli ucu və rozetka ucu var. Polad sinfi əsasən B, X42, X46, X52, X56, X65, X70 dərəcəlidir.

Diksiz Boru

Polad dərəcəsi: B, X42, X52, X60, X65, X70

Ölçü: 1"/2" - 24"

Proses: isti yayma, isti genişlənmə

Qaynaq borusu

Polad dərəcəsi: B, X42, X52, X60, X65, X70, X80

Ölçü: 2"-30"

Proses: ERW, SSAW, LSAW, HFW, JCOE.

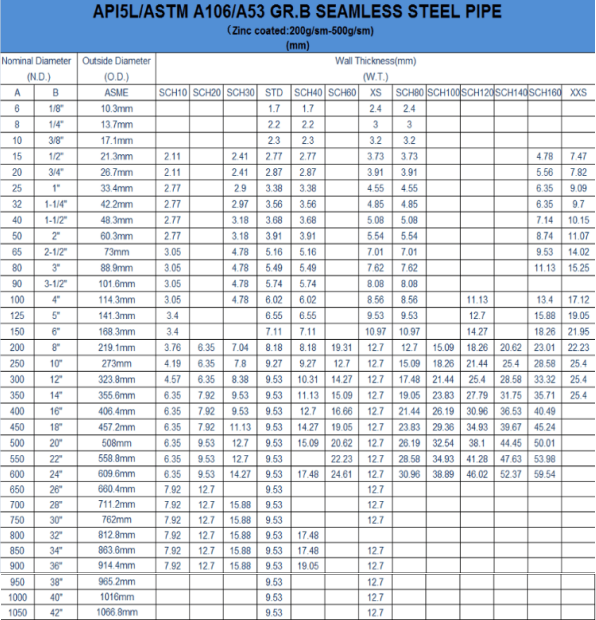

Standart:API 5L / ISO 3183 İsti haddelenmiş

Növ:Sorunsuz / ERW / Qaynaqlanmış / Hazırlanmış / CDW

Xarici diametri ölçüsü:3/8" NB - 30" NB (Nominal Buruq Ölçüsü)

Divar qalınlığı:XXS Cədvəli üçün Cədvəl 20 (İstəyə görə daha ağır) 250 mm qalınlığa qədər

Uzunluq:5 ilə 7 Metr, 09 ilə 13 Metr, Tək Təsadüfi Uzunluq, Cüt Təsadüfi Uzunluq və Ölçüsü fərdiləşdirin.

Boru uçları:Düz Uçlar / Eğik Uçlar / Bağlama

Səthi örtük:Epoksi Kaplama / Rəngli Boya Kaplaması / 3LPE Kaplama.

Qiymətlər:API 5l Sinif B X42, API 5l Sinif B X46, API 5l Dərəcəsi B X52, API 5l Dərəcəsi B X56, API 5l Dərəcəsi B X60, API 5l Sinif B X65, API 5l Dərəcəsi B X70

Api 5l Boru Kimyəvi və Mexaniki Xüsusiyyətləri

API 5L borusunun məhsuldarlıq gücü material dərəcəsi təyinatında X-dən sonra gələn nömrə ilə müəyyən edilir (kvadrat düym üçün kiloqramla – yəni KSI). Beləliklə, məsələn, API 5L X52 borusu minimum 52 KSI məhsuldarlığa malikdir.

Cədvəldə API 5L polad borularının PSL1 və PSL2 A dərəcəlidən X70 dərəcəsinə qədər kimyəvi tərkibi, eləcə də mexaniki xüsusiyyətləri göstərilir.

API 5L Line Pipe tətbiqi

- Neft və Qaz Sənayesi

- Təbii Qaz Sənayesi

- Neft sənayesi

- Mayenin daşınması

- Avtomobil tətbiqi

- İnfrastruktur tikintisi

- Sənaye istehsalı

- Tikinti layihəsi

- Kimya Sənayesi

Kimyəvi Analiz (%):

| Standart | Boru növü | Sinif | Dərəcə | C | Si | Mn | P | S | V | Nb | Ti |

| maks | maks | maks | maks | maks | maks | maks | maks | ||||

| API SPEC 5L | SMLS | PLS1 | L245 B L290 X42 L320 X46 L360 X52 L390 X56 L415 X60 L450 X65 L485 X70 L245N BN | 0,28 0,28 0,28 0,28 0,28 0,28 0,28 0,28 0,24 | 0.4 | 1,20 1,30 1,40 1,40 1,40 1,40 1,40 1,40 1,20 | 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,025 | 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,015 | ——— | ——— | 0.04 |

| PLS2 | L290N X42N | 0.24 | 0.4 | 1.2 | 0,025 | 0,015 | 0.06 | 0.05 | 0.04 | ||

| L320N X46N | 0.24 | 0.4 | 1.4 | 0,025 | 0,015 | 0.07 | 0.05 | 0.04 | |||

| L360N X52N | 0.24 | 0,45 | 1.4 | 0,025 | 0,015 | 0.1 | 0.05 | 0.04 | |||

| L390N X56N | 0.24 | 0,45 | 1.4 | 0,025 | 0,015 | 0.1 | 0.05 | 0.04 | |||

| L415N X60N | 0.24 | 0,45 | 1.4 | 0,025 | 0,015 | 0.1 | 0.05 | 0.04 | |||

| QAYNAQ | PLS1 | L245 B | 0.26 | - | 1.2 | - | 0.03 | 0.03 | - | - | |

| L290 X42 | 0.26 | - | 1.3 | - | 0.03 | 0.03 | - | - | |||

| L320 X46 | 0.26 | - | 1.4 | - | 0.03 | 0.03 | - | - | |||

| L360 X52 | 0.26 | - | 1.4 | - | 0.03 | 0.03 | - | - | |||

| L390 X56 | 0.26 | - | 1.4 | - | 0.03 | 0.03 | - | - | |||

| L415 X60 | 0.26 | - | 1.4 | - | 0.03 | 0.03 | - | - | |||

| L450 X65 | 0.26 | - | 1.45 | - | 0.03 | 0.03 | - | - | |||

| L485 X70 | 0.26 | - | 1.65 | - | 0.03 | 0.03 | - | - | |||

| PLS2 | L245M BM | 0.22 | 0,45 | 1.2 | 0,025 | 0,015 | 0.05 | 0.05 | 0.04 | ||

| L290M X42M | 0.22 | 0,45 | 1.3 | 0,025 | 0,015 | 0.05 | 0.05 | 0.04 | |||

| L320M X46M | 0.22 | 0,45 | 1.3 | 0,025 | 0,015 | 0.05 | 0.05 | 0.04 | |||

| L360M X52M | 0.22 | 0,45 | 1.4 | 0,025 | 0,015 | - | - | - | |||

| L390M X56M | 0.22 | 0,45 | 1.4 | 0,025 | 0,015 | - | - | - | |||

| L415M X60M | 0.12 | 0,45 | 1.6 | 0,025 | 0,015 | - | - | - | |||

| L450M X65M | 0.12 | 0,45 | 1.6 | 0,025 | 0,015 | - | - | - | |||

| L485M X70M | 0.12 | 0,45 | 1.7 | 0,025 | 0,015 | - | - | - | |||

| L555M X80M | 0.12 | 0,45 | 1.85 | 0,025 | 0,015 | - | - | - |

Mexanik Xüsusiyyətlər:

| Standart | Sinif | Dərəcə | Çıxış gücü (MPa) az deyil | Dartma gücü (MPa) | Uzatma (%) | YS/TS | |

| API SPEC 5L ISO 3183 | PLS1 | L245B | min | 245 | 415 | b | - |

| L290X42 | min | 290 | 415 | b | - | ||

| L320X46 | min | 320 | 435 | b | - | ||

| L360X52 | min | 360 | 460 | b | - | ||

| L390X56 | min | 390 | 490 | b | - | ||

| L415X60 | min | 415 | 520 | b | - | ||

| L450X60 | min | 450 | 535 | b | - | ||

| L485X70 | min | 485 | 570 | b | - | ||

| PLS2 | L245N BN | min | 245 | 415 | b | - | |

| L245M BM | maks | 450 | 760 | b | 0.93 | ||

| L290NX42N | min | 290 | 415 | b | - | ||

| L290MX42M | maks | 495 | 760 | b | 0.93 | ||

| L320NX46N | min | 320 | 435 | b | - | ||

| L320MX46M | maks | 525 | 760 | b | 0.93 | ||

| L360NX52N | min | 360 | 460 | b | - | ||

| L360MX52M | maks | 530 | 760 | b | 0.93 | ||

| L390NX56N | min | 390 | 490 | b | - | ||

| L390MX56M | maks | 545 | 760 | b | 0.93 | ||

| L415NX60N | min | 415 | 520 | b | - | ||

| L415MX60M | maks | 565 | 760 | b | 0.93 | ||

| L450MX65M | min | 450 | 535 | b | - | ||

| maks | 600 | 760 | b | 0.93 | |||

| L485MX70M | min | 485 | 570 | b | - | ||

| maks | 635 | 760 | b | 0.93 | |||

| L555MX80M | min | 555 | 625 | b | - | ||

| maks | 705 | 825 | b | 0.93 |

Sərtlik:

| Standart | Dərəcə | Boru gövdəsinin eninə minimum təsiri | Qaynaq tikişinin eninə minimum təsiri (J) | |||||

| (J) | ||||||||

| D=508 | 508 mm | 762 mm | 914 mm | 1219 mm | D<1422 mm | D=1422 mm | ||

| API SPEC 5L | =L415×60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415×60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) | |

| =L450×65 | ||||||||

| >L450×65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) | |

| =L485×70 | ||||||||

| >L485×70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) | |

| =L555×80 | ||||||||

Qeyd: (1) Cədvəldəki dəyərlər tam ölçülü standart nümunə üçün uyğun olmalıdır.

(2) Mötərizə daxilindəki dəyərlər minimum tək dəyərdir, kənar mötərizə orta qiymətdir.

(3) Test temperaturu: 0°C.

Korroziyaya qarşı su əsaslı boya

İsti Rolling Dikişsiz Polad Xətt Boru İstehsalı / İstehsal prosesləri

Yuvarlanan Dairəvi Kətanlar – Müayinə – Kəsmə – Qızdırma – Pirsinq – Uzatma – Bir az gərginlik azaldılması – Düzləşdirmə – Korp ucun kəsilməsi – Vizual yoxlama – NDT – Hidrostatik sınaq – Prosesin sonları – Məhsulun yoxlanılması – Rənglənmə və markalanma – Qablaşdırma – Anbar

Soyuq çəkilmiş (yuvarlanmış) tikişsiz polad boru istehsalı prosesi

Ana boru (Adətən isti haddelenmiş borular üçün) – Yoxlama – Tavlama – Uçların müalicəsi (Vurma və Qazma) – Turşulama – Taşlama – Fosforlaşdırma (Annoit) – Soyuq çəkilmə (Yüklənmiş) – Yağdan təmizləmə və Təmizləmə – İstilik müalicəsi (Məhsulla müalicə) – Düzləşdirmə – Hidrostatik sınaq – Boyama və Markalama – Anbar