O aço inoxidável é um material versátil composto por uma liga de aço e uma pequena porcentagem de cromo - a adição de cromo aumenta a resistência à corrosão do material, característica que deu nome ao aço inoxidável. Como o aço inoxidável também exige pouca manutenção, é resistente à oxidação e não afeta outros metais com os quais entra em contato, ele é frequentemente usado em uma grande variedade de aplicações, especialmente na fabricação de tubulações e tubulações.

O tubo de aço inoxidável é usado principalmente em sistemas de tubulação para transporte de fluidos ou gases. O tubo de aço inoxidável resiste à oxidação, tornando-o uma solução de baixa manutenção adequada para aplicações químicas e de alta temperatura. Por ser facilmente limpo e higienizado, o tubo de aço inoxidável também é desejado para aplicações que envolvem alimentos, bebidas e aplicações farmacêuticas.

Tubo de aço inoxidável soldado

Normas: ASTM A312

Classes: 304/L e 316/L

Tamanhos: 1/4" a 36"

Horários: 10, 20, 40, 80

Tubo de aço inoxidável sem costura

Normas: ASTM A312

Classes: 304/L e 316/L

Tamanhos: 1/4" a 20"

Horários: 10s, 40s, 80s, 160 e XXH

Verdadeiro 40, Verdadeiro 80

Equipamento:

Aplicação de tubo de aço inoxidável

- Bancadas de cozinha, pias, gamelas, equipamentos e eletrodomésticos

- Painéis arquitetônicos, grades e acabamentos

- Recipientes para produtos químicos, inclusive para transporte

- Trocadores de calor

- Telas tecidas ou soldadas para mineração, pedreiras e filtragem de água

- Fixadores roscados

- Sistemas de Abastecimento de Água

- Central Elétrica

- Indústria de papel e celulose

- Aplicações de uso geral

- Indústria de Fabricação

- Indústria de Processamento de Alimentos

- Projeto Estrutural Industrial

- Oleoduto e Gasoduto

- Indústria Química

- Encanamento Industrial

Nossas vantagens:

1. Fornecedor líder de serviços de produtos e exportador de tubos de aço na China

2. Preço competitivo e qualidade de nossa própria fábrica

3. Integração completa de recursos

4. Passou na certificação ISO9001, CE, SGS todos os anos

5. Melhor serviço com resposta 24 horas

6. Métodos de pagamento flexíveis

7. Forte capacidade de produção

8. Entrega rápida e embalagem padrão de exportação

9.OEM/ODM

| NB | Tamanho | OD mm | 40S mm | 5S mm | 10S mm | S 10 mm | S 20 mm | S 40 mm | S 60 mm | XS/80S mm | S 80 mm | S 100 mm | S 120 mm | S 140 mm | S 160 mm | XXS mm |

| 1/8” | 10.29 | 1,24 | 1,73 | 2.41 | ||||||||||||

| 1/4” | 13,72 | 1,65 | 2.24 | 3.02 | ||||||||||||

| 3/8” | 17h15 | 1,65 | 2.31 | 3.20 | ||||||||||||

| 15 | 1/2” | 21h34 | 2,77 | 1,65 | 2.11 | 2,77 | 3,73 | 3,73 | 4,78 | 7,47 | ||||||

| 20 | 3/4” | 26,67 | 2,87 | 1,65 | 2.11 | 2,87 | 3,91 | 3,91 | 5,56 | 7,82 | ||||||

| 25 | 1” | 33h40 | 3,38 | 1,65 | 2,77 | 3,38 | 4,55 | 4,55 | 6h35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3,56 | 1,65 | 2,77 | 3,56 | 4,85 | 4,85 | 6h35 | 9,70 | ||||||

| 40 | 1 1/2” | 48,26 | 3,68 | 1,65 | 2,77 | 3,68 | 5.08 | 5.08 | 7.14 | 10h15 | ||||||

| 50 | 2” | 60,33 | 3,91 | 1,65 | 2,77 | 3,91 | 5,54 | 5,54 | 9,74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9,53 | 14.02 | ||||||

| 80 | 3” | 88,90 | 5,49 | 2.11 | 3.05 | 5,49 | 7,62 | 7,62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101,60 | 5,74 | 2.11 | 3.05 | 5,74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114h30 | 6.02 | 2.11 | 3.05 | 6.02 | 8,56 | 8,56 | 11.12 | 13h49 | 17.12 | |||||

| 125 | 5” | 141,30 | 6,55 | 2,77 | 3h40 | 6,55 | 9,53 | 9,53 | 12h70 | 15,88 | 19.05 | |||||

| 150 | 6” | 168,27 | 7.11 | 2,77 | 3h40 | 7.11 | 10,97 | 10,97 | 14.27 | 18h26 | 21h95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2,77 | 3,76 | 6h35 | 8.18 | 10h31 | 12h70 | 12h70 | 15.09 | 19h26 | 20,62 | 23.01 | 22.23 | |

| 250 | 10” | 273,05 | 9.27 | 3h40 | 4.19 | 6h35 | 9.27 | 12h70 | 12h70 | 15.09 | 19h26 | 21h44 | 25h40 | 28,58 | 25h40 | |

| 300 | 12” | 323,85 | 9,53 | 3,96 | 4,57 | 6h35 | 10h31 | 14.27 | 12h70 | 17h48 | 21h44 | 25h40 | 28,58 | 33,32 | 25h40 | |

| 350 | 14” | 355,60 | 9,53 | 3,96 | 4,78 | 6h35 | 7,92 | 11.13 | 15.09 | 12h70 | 19.05 | 23,83 | 27,79 | 31,75 | 35,71 | |

| 400 | 16” | 406,40 | 9,53 | 4.19 | 4,78 | 6h35 | 7,92 | 12h70 | 16,66 | 12h70 | 21h44 | 26.19 | 30,96 | 36,53 | 40,49 | |

| 450 | 18” | 457,20 | 9,53 | 4.19 | 4,78 | 6h35 | 7,92 | 14.27 | 19.05 | 12h70 | 23,83 | 29.36 | 34,93 | 39,67 | 45,24 | |

| 500 | 20” | 508,00 | 9,53 | 4,78 | 5,54 | 6h35 | 9,53 | 15.09 | 20,62 | 12h70 | 26.19 | 32,54 | 38.10 | 44,45 | 50.01 | |

| 550 | 22” | 558,80 | 9,53 | 4,78 | 5,54 | 6h35 | 9,53 | 22.23 | 12h70 | 28,58 | 34,93 | 41,28 | 47,63 | 53,98 | ||

| 600 | 24” | 609,60 | 9,53 | 5,54 | 6h35 | 6h35 | 9,53 | 17h48 | 24,61 | 12h70 | 30,96 | 38,89 | 46.02 | 52,37 | 59,54 | |

| 650 | 26” | 660,40 | 9,53 | 7,92 | 12h70 | 12h70 | ||||||||||

| 700 | 28” | 711.20 | 9,53 | 7,92 | 12h70 | 12h70 | ||||||||||

| 750 | 30” | 762,00 | 9,53 | 6h35 | 7,92 | 7,92 | 12h70 | 12h70 | ||||||||

| 800 | 32” | 812,80 | 9,53 | 7,92 | 12h70 | 17h48 | 12h70 | |||||||||

| 850 | 34” | 863,60 | 9,53 | 7,92 | 12h70 | 17h48 | 12h70 | |||||||||

| 900 | 36” | 914,40 | 9,53 | 7,92 | 12h70 | 19.05 | 12h70 |

Composição Química

| Notas | C máx. | Mn máx. | P máx. | S máx. | Si máx. | Cr | Ni | Mo |

| 304 | 0,08 | 2h00 | 0,04 | 0,03 | 0,075 | 18h00-20h00 | 8h00-11h00 | / |

| 304L | 0,035 | 2h00 | 0,04 | 0,03 | 0,075 | 18h00-20h00 | 8h00-13h00 | / |

| 316 | 0,08 | 2h00 | 0,04 | 0,03 | 0,075 | 16h00-18h00 | 11h00-14h00 | 2h00-3h00 |

| 316L | 0,035 | 2h00 | 0,04 | 0,03 | 0,075 | 16h00-18h00 | 10h00-15h00 | 2h00-3h00 |

Propriedades Mecânicas

| Notas | Item | Tensão psi | Rendimento psi | Alongar % | Dureza Rockwell |

| 304 | Recozido | 85.000-105.000 | 35.000-75.000 | 20-55 | 80-95 |

| 304L | Recozido I1/8 Difícil | 80.000-105.000 | 30.000-75.000 | 20-55 | 75-95 |

| 316 | Recozido | 85.000 minutos | 35.000 minutos | 50 minutos | 80 minutos |

| Recozido | 80.000 minutos | 30.000 minutos | 50 minutos | 75 minutos |

Pintura e Revestimento:Recozido, Decapagem, Polido

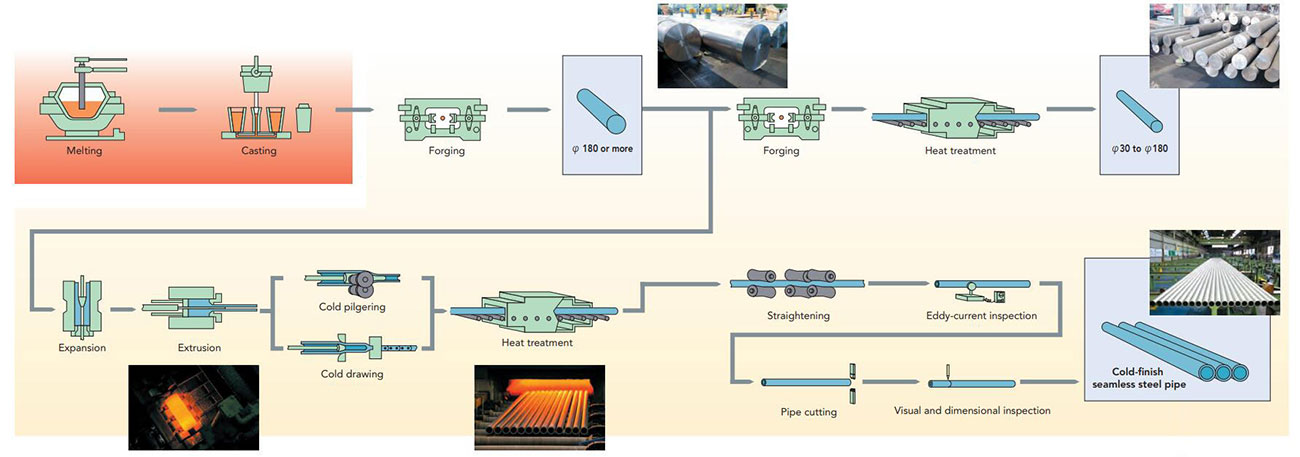

Processo de fabricação de tubo de aço sem costura