Paslanmaz çelik, çelik alaşımı ve az miktarda kromdan oluşan çok yönlü bir malzemedir; kromun eklenmesi, paslanmaz çeliğe adını kazandıran bir özellik olan malzemenin korozyon direncine katkıda bulunur. Paslanmaz çelik aynı zamanda az bakım gerektirdiğinden, oksidasyona dirençli olduğundan ve temas ettiği diğer metalleri etkilemediğinden, özellikle boru ve boru imalatında olmak üzere çok çeşitli uygulamalarda sıklıkla kullanılır.

Paslanmaz çelik boru öncelikle sıvıların veya gazların taşınmasına yönelik boru sistemlerinde kullanılır. Paslanmaz çelik boru oksidasyona karşı dayanıklıdır, bu da onu yüksek sıcaklık ve kimyasal uygulamalara uygun, az bakım gerektiren bir çözüm haline getirir. Kolayca temizlenip sterilize edilebildiği için paslanmaz çelik borular yiyecek, içecek ve farmasötik uygulamaları içeren uygulamalar için de tercih edilmektedir.

Kaynaklı paslanmaz çelik boru

Standartlar: ASTM A312

Kaliteler: 304/L ve 316/L

Boyutlar: 1/4" ila 36"

Programlar: 10'lar, 20'ler, 40'lar, 80'ler

Dikişsiz Paslanmaz Çelik Boru

Standartlar: ASTM A312

Kaliteler: 304/L ve 316/L

Boyutlar: 1/4" ila 20"

Programlar: 10'lar, 40'lar, 80'ler, 160 ve XXH

Doğru 40, Doğru 80

Teçhizat:

Paslanmaz Çelik Boru Uygulaması

- Mutfak tezgahları, lavabolar, tekneler, ekipman ve cihazlar

- Mimari paneller, korkuluklar ve kaplamalar

- Taşıma amaçlı olanlar da dahil olmak üzere kimyasal kaplar

- Isı Eşanjörleri

- Madencilik, taşocakçılığı ve su filtrelemeye yönelik dokuma veya kaynaklı elekler

- Dişli bağlantı elemanları

- Su Temini Sistemleri

- Enerji Santrali

- Kağıt ve kağıt hamuru endüstrisi

- Genel Amaçlı Uygulamalar

- İmalat Sanayi

- Gıda İşleme Sanayi

- Endüstriyel Yapı Projesi

- Petrol ve Gaz Boru Hattı

- Kimya Endüstrisi

- Sıhhi Tesisat Endüstriyel

Avantajlarımız:

1. Çin'in önde gelen ürün servis sağlayıcısı ve çelik boru ihracatçısı

2. Kendi fabrikamızdan rekabetçi fiyat ve kalite

3. Tek Noktadan Kaynak Entegrasyonu

4. Her yıl ISO9001, CE, SGS sertifikasını geçti

5. 24 saat yanıtla en iyi hizmet

6. Esnek ödeme yöntemleri

7. Güçlü üretim kapasitesi

8. Hızlı teslimat ve standart ihracat ambalajı

9.OEM/ODM

| NB | Boyut | OD mm | 40S mm | 5S mm | 10S mm | S10 mm | S20 mm | S 40 mm | S 60 mm | XS/80S mm | S 80 mm | S 100 mm | S 120 mm | S 140 mm | S 160 mm | XXS mm |

| 1/8" | 10.29 | 1.24 | 1.73 | 2.41 | ||||||||||||

| 1/4" | 13.72 | 1.65 | 2.24 | 3.02 | ||||||||||||

| 3/8" | 17.15 | 1.65 | 2.31 | 3.20 | ||||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4" | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4" | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5" | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10" | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12" | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14" | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16" | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508,00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22" | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24" | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30" | 762,00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32" | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 |

Kimyasal Bileşim

| Notlar | Cmaks | Mn maks | Pmaks | Smaks | Si maksimum | Cr | Ni | Mo |

| 304 | 0,08 | 2.00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0,035 | 2.00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0,08 | 2.00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0,035 | 2.00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Mekanik Özellikler

| Notlar | Öğeci | Çekme Psi'si | Verim Psi | Uzama %'si | Rockwell Sertliği |

| 304 | Tavlanmış | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | Tavlanmış I1/8 Zor | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Tavlanmış | 85000 dk | 35000 dk | 50 dakika | 80 dakika |

| Tavlanmış | 80000 dk | 30000 dk | 50 dakika | 75 dakika |

Boyama ve Kaplama: Tavlanmış, Asitleme, Cilalı

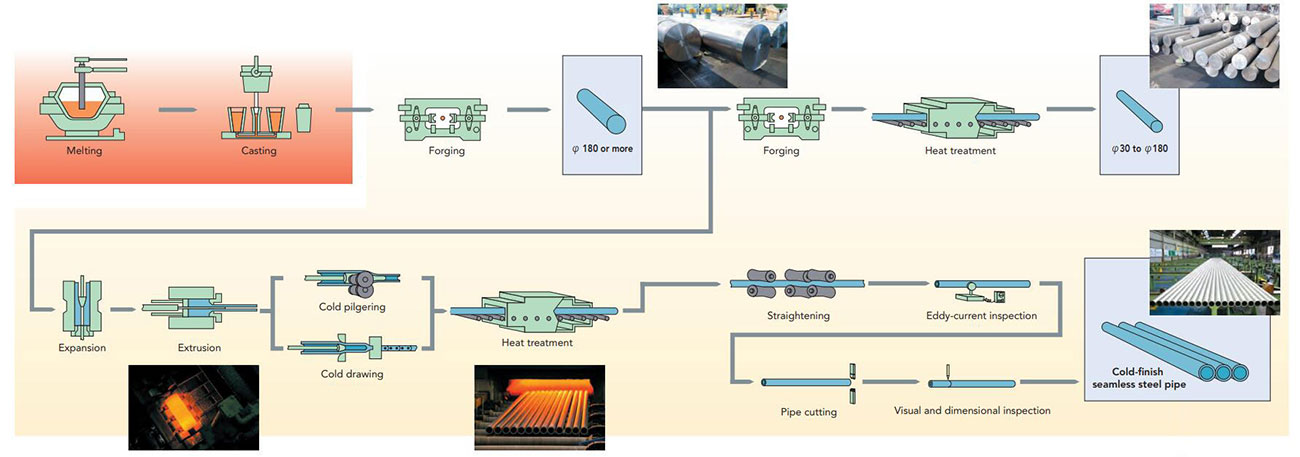

Dikişsiz Çelik Boru Üretim Süreci