Thép không gỉ là một vật liệu linh hoạt bao gồm hợp kim thép và một tỷ lệ nhỏ crom - việc bổ sung crom làm tăng thêm khả năng chống ăn mòn của vật liệu, một đặc điểm khiến thép không gỉ có tên như vậy. Vì thép không gỉ cũng ít phải bảo trì, chống oxy hóa và không ảnh hưởng đến các kim loại khác mà nó tiếp xúc nên nó thường được sử dụng trong rất nhiều ứng dụng, đặc biệt là trong sản xuất đường ống và ống dẫn.

Ống thép không gỉ chủ yếu được sử dụng trong các hệ thống đường ống để vận chuyển chất lỏng hoặc khí. Ống thép không gỉ chống lại quá trình oxy hóa, làm cho nó trở thành một giải pháp bảo trì thấp, phù hợp với các ứng dụng hóa học và nhiệt độ cao. Vì dễ dàng làm sạch và vệ sinh nên ống thép không gỉ cũng được ưa chuộng cho các ứng dụng liên quan đến thực phẩm, đồ uống và dược phẩm.

Ống thép không gỉ hàn

Tiêu chuẩn: ASTM A312

Cấp: 304/L và 316/L

Kích thước: 1/4" đến 36"

Lịch trình: 10, 20, 40, 80

Ống thép không gỉ liền mạch

Tiêu chuẩn: ASTM A312

Cấp: 304/L và 316/L

Kích thước: 1/4" đến 20"

Lịch trình: 10, 40, 80, 160 và XXH

Đúng 40, Đúng 80

Thiết bị:

Ứng dụng của ống thép không gỉ

- Bàn bếp, bồn rửa, máng, thiết bị, đồ dùng nhà bếp

- Tấm kiến trúc, lan can và trang trí

- Thùng đựng hóa chất, kể cả thùng vận chuyển

- Bộ trao đổi nhiệt

- Màn chắn dệt hoặc hàn dùng trong khai thác mỏ, khai thác đá và lọc nước

- Ốc vít có ren

- Hệ thống cấp nước

- Nhà máy điện

- Công nghiệp giấy và bột giấy

- Ứng dụng mục đích chung

- Công nghiệp chế tạo

- Công nghiệp chế biến thực phẩm

- Dự án kết cấu công nghiệp

- Đường ống dẫn dầu khí

- Công nghiệp hóa chất

- Hệ thống nước công nghiệp

Ưu điểm của chúng tôi:

1. Nhà cung cấp dịch vụ sản phẩm và xuất khẩu ống thép hàng đầu Trung Quốc

2. Giá cả và chất lượng cạnh tranh từ nhà máy của chúng tôi

3. Tích hợp tài nguyên một cửa

4. Đạt chứng nhận ISO 9001, CE, SGS hàng năm

5. Dịch vụ tốt nhất với phản hồi 24 giờ

6. Phương thức thanh toán linh hoạt

7. Năng lực sản xuất mạnh

8. Giao hàng nhanh và bao bì xuất khẩu tiêu chuẩn

9.OEM/ODM

| NB | Kích cỡ | OD mm | 40S mm | 5S mm | 10S mm | S 10 mm | S 20 mm | S 40 mm | S 60 mm | XS/80S mm | S 80 mm | S 100 mm | S 120 mm | S 140 mm | S 160 mm | XXS mm |

| 1/8” | 29/10 | 1,24 | 1,73 | 2,41 | ||||||||||||

| 1/4” | 13,72 | 1,65 | 2,24 | 3.02 | ||||||||||||

| 3/8” | 17:15 | 1,65 | 2,31 | 3,20 | ||||||||||||

| 15 | 1/2” | 21.34 | 2,77 | 1,65 | 2.11 | 2,77 | 3,73 | 3,73 | 4,78 | 7,47 | ||||||

| 20 | 3/4” | 26,67 | 2,87 | 1,65 | 2.11 | 2,87 | 3,91 | 3,91 | 5,56 | 7,82 | ||||||

| 25 | 1” | 33:40 | 3,38 | 1,65 | 2,77 | 3,38 | 4,55 | 4,55 | 6:35 | 9.09 | ||||||

| 32 | 1 1/4” | 42,16 | 3,56 | 1,65 | 2,77 | 3,56 | 4,85 | 4,85 | 6:35 | 9 giờ 70 | ||||||

| 40 | 1 1/2” | 48,26 | 3,68 | 1,65 | 2,77 | 3,68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60,33 | 3,91 | 1,65 | 2,77 | 3,91 | 5,54 | 5,54 | 9,74 | 07/11 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7,01 | 7,01 | 9,53 | 14.02 | ||||||

| 80 | 3” | 88,90 | 5,49 | 2.11 | 3.05 | 5,49 | 7,62 | 7,62 | 13/11 | 15,24 | ||||||

| 90 | 3 1/2” | 101,60 | 5,74 | 2.11 | 3.05 | 5,74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114,30 | 6.02 | 2.11 | 3.05 | 6.02 | 8,56 | 8,56 | 12/11 | 13:49 | 17.12 | |||||

| 125 | 5” | 141,30 | 6,55 | 2,77 | 3,40 | 6,55 | 9,53 | 9,53 | 12:70 | 15,88 | 19.05 | |||||

| 150 | 6” | 168,27 | 7.11 | 2,77 | 3,40 | 7.11 | 10,97 | 10,97 | 14,27 | 18,26 | 21:95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2,77 | 3,76 | 6:35 | 8.18 | 10.31 | 12:70 | 12:70 | 15.09 | 19,26 | 20,62 | 23.01 | 22,23 | |

| 250 | 10” | 273,05 | 9,27 | 3,40 | 4.19 | 6:35 | 9,27 | 12:70 | 12:70 | 15.09 | 19,26 | 21.44 | 25h40 | 28,58 | 25h40 | |

| 300 | 12” | 323,85 | 9,53 | 3,96 | 4,57 | 6:35 | 10.31 | 14,27 | 12:70 | 17:48 | 21.44 | 25h40 | 28,58 | 33,32 | 25h40 | |

| 350 | 14” | 355,60 | 9,53 | 3,96 | 4,78 | 6:35 | 7,92 | 13/11 | 15.09 | 12:70 | 19.05 | 23,83 | 27,79 | 31,75 | 35,71 | |

| 400 | 16” | 406,40 | 9,53 | 4.19 | 4,78 | 6:35 | 7,92 | 12:70 | 16,66 | 12:70 | 21.44 | 26.19 | 30,96 | 36,53 | 40,49 | |

| 450 | 18” | 457,20 | 9,53 | 4.19 | 4,78 | 6:35 | 7,92 | 14,27 | 19.05 | 12:70 | 23,83 | 29,36 | 34,93 | 39,67 | 45,24 | |

| 500 | 20” | 508,00 | 9,53 | 4,78 | 5,54 | 6:35 | 9,53 | 15.09 | 20,62 | 12:70 | 26.19 | 32,54 | 38.10 | 44,45 | 50,01 | |

| 550 | 22” | 558,80 | 9,53 | 4,78 | 5,54 | 6:35 | 9,53 | 22,23 | 12:70 | 28,58 | 34,93 | 41,28 | 47,63 | 53,98 | ||

| 600 | 24” | 609,60 | 9,53 | 5,54 | 6:35 | 6:35 | 9,53 | 17:48 | 24.61 | 12:70 | 30,96 | 38,89 | 46.02 | 52,37 | 59,54 | |

| 650 | 26” | 660,40 | 9,53 | 7,92 | 12:70 | 12:70 | ||||||||||

| 700 | 28” | 711,20 | 9,53 | 7,92 | 12:70 | 12:70 | ||||||||||

| 750 | 30” | 762,00 | 9,53 | 6:35 | 7,92 | 7,92 | 12:70 | 12:70 | ||||||||

| 800 | 32” | 812,80 | 9,53 | 7,92 | 12:70 | 17:48 | 12:70 | |||||||||

| 850 | 34” | 863,60 | 9,53 | 7,92 | 12:70 | 17:48 | 12:70 | |||||||||

| 900 | 36” | 914,40 | 9,53 | 7,92 | 12:70 | 19.05 | 12:70 |

Thành phần hóa học

| Điểm | C tối đa | Mn tối đa | P tối đa | S tối đa | Si tối đa | Cr | Ni | Mo |

| 304 | 0,08 | 2,00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0,035 | 2,00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0,08 | 2,00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 | 11.00-14.00 | 2,00-3,00 |

| 316L | 0,035 | 2,00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 | 10.00-15.00 | 2,00-3,00 |

Tính chất cơ học

| Điểm | Mục | Độ bền kéo Psi | Năng suất Psi | % kéo dài | Độ cứng Rockwell |

| 304 | Ủ | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | Ủ I1/8 Cứng | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Ủ | 85000 phút | 35000 phút | 50 phút | 80 phút |

| Ủ | 80000 phút | 30000 phút | 50 phút | 75 phút |

Sơn & Sơn phủ:Ủ, ngâm chua, đánh bóng

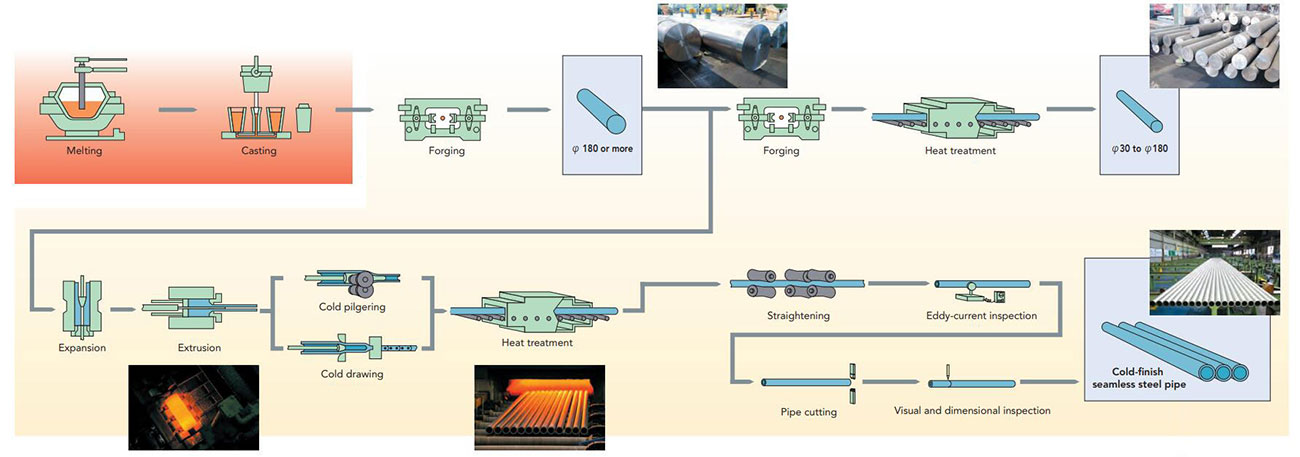

Quy trình sản xuất ống thép liền mạch