Stal nierdzewna to wszechstronny materiał składający się ze stopu stali i niewielkiej ilości chromu — dodatek chromu zwiększa odporność materiału na korozję, dzięki czemu stal nierdzewna zyskała swoją nazwę. Ponieważ stal nierdzewna jest również łatwa w utrzymaniu, odporna na utlenianie i nie wpływa na inne metale, z którymi ma kontakt, jest często stosowana w szerokim zakresie zastosowań, zwłaszcza w produkcji rurociągów.

Rury ze stali nierdzewnej są stosowane głównie w systemach rurociągów do transportu płynów lub gazów. Rura ze stali nierdzewnej jest odporna na utlenianie, co czyni ją rozwiązaniem wymagającym niewielkiej konserwacji i odpowiednim do zastosowań wysokotemperaturowych i chemicznych. Ponieważ rury ze stali nierdzewnej można łatwo czyścić i odkażać, są one również pożądane w zastosowaniach związanych z żywnością, napojami i zastosowaniami farmaceutycznymi.

Spawana rura ze stali nierdzewnej

Normy: ASTM A312

Gatunki: 304/L i 316/L

Rozmiary: 1/4" do 36"

Harmonogramy: 10, 20, 40, 80

Bezszwowa rura ze stali nierdzewnej

Normy: ASTM A312

Gatunki: 304/L i 316/L

Rozmiary: 1/4" do 20"

Harmonogramy: 10, 40, 80, 160 i XXH

Prawdziwe 40, Prawdziwe 80

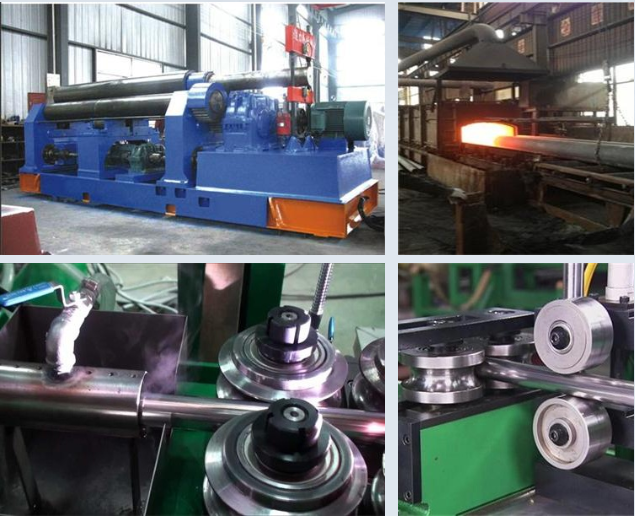

Sprzęt:

Zastosowanie rurki ze stali nierdzewnej

- Ławy kuchenne, zlewozmywaki, koryta, sprzęt i urządzenia

- Panele architektoniczne, balustrady i wykończenia

- Kontenery chemiczne, w tym do transportu

- Wymienniki ciepła

- Sita tkane lub spawane dla górnictwa, kamieniołomów i filtracji wody

- Gwintowane elementy złączne

- Systemy zaopatrzenia w wodę

- Elektrownia

- Przemysł papierniczy i celulozowy

- Zastosowania ogólnego przeznaczenia

- Przemysł przetwórczy

- Przemysł spożywczy

- Projekt konstrukcji przemysłowej

- Rurociąg naftowy i gazowy

- Przemysł chemiczny

- Hydraulika przemysłowa

Nasze zalety:

1. Wiodący w Chinach dostawca usług produktowych i eksporter rur stalowych

2. Konkurencyjna cena i jakość z naszej własnej fabryki

3. Kompleksowa integracja zasobów

4. Co roku przechodził certyfikat ISO9001, CE, SGS

5. Najlepsza obsługa z reakcją 24-godzinną

6. Elastyczne metody płatności

7. Silne moce produkcyjne

8. Szybka dostawa i standardowe opakowanie eksportowe

9. OEM/ODM

| NB | Rozmiar | OD mm | 40 lat mm | 5S mm | 10 s mm | S 10 mm | S 20 mm | S 40 mm | S 60 mm | XS/80S mm | S 80 mm | S 100 mm | S 120 mm | S 140 mm | S 160 mm | XXS mm |

| 1/8” | 10.29 | 1,24 | 1,73 | 2.41 | ||||||||||||

| 1/4” | 13.72 | 1,65 | 2.24 | 3.02 | ||||||||||||

| 3/8” | 17.15 | 1,65 | 2.31 | 3.20 | ||||||||||||

| 15 | 1/2” | 21.34 | 2,77 | 1,65 | 2.11 | 2,77 | 3,73 | 3,73 | 4,78 | 7,47 | ||||||

| 20 | 3/4” | 26,67 | 2,87 | 1,65 | 2.11 | 2,87 | 3,91 | 3,91 | 5,56 | 7,82 | ||||||

| 25 | 1” | 33.40 | 3,38 | 1,65 | 2,77 | 3,38 | 4,55 | 4,55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3,56 | 1,65 | 2,77 | 3,56 | 4,85 | 4,85 | 6.35 | 9,70 | ||||||

| 40 | 1 1/2” | 48,26 | 3,68 | 1,65 | 2,77 | 3,68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60,33 | 3,91 | 1,65 | 2,77 | 3,91 | 5,54 | 5,54 | 9,74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9,53 | 14.02 | ||||||

| 80 | 3” | 88,90 | 5,49 | 2.11 | 3.05 | 5,49 | 7,62 | 7,62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101,60 | 5,74 | 2.11 | 3.05 | 5,74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114,30 | 6.02 | 2.11 | 3.05 | 6.02 | 8,56 | 8,56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141,30 | 6,55 | 2,77 | 3.40 | 6,55 | 9,53 | 9,53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168,27 | 7.11 | 2,77 | 3.40 | 7.11 | 10,97 | 10,97 | 14.27 | 18.26 | 21,95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2,77 | 3,76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28,58 | 25.40 | |

| 300 | 12” | 323,85 | 9,53 | 3,96 | 4,57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28,58 | 33.32 | 25.40 | |

| 350 | 14” | 355,60 | 9,53 | 3,96 | 4,78 | 6.35 | 7,92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27,79 | 31,75 | 35,71 | |

| 400 | 16” | 406,40 | 9,53 | 4.19 | 4,78 | 6.35 | 7,92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30,96 | 36,53 | 40,49 | |

| 450 | 18” | 457,20 | 9,53 | 4.19 | 4,78 | 6.35 | 7,92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34,93 | 39,67 | 45.24 | |

| 500 | 20” | 508,00 | 9,53 | 4,78 | 5,54 | 6.35 | 9,53 | 15.09 | 20.62 | 12.70 | 26.19 | 32,54 | 38.10 | 44,45 | 50.01 | |

| 550 | 22” | 558,80 | 9,53 | 4,78 | 5,54 | 6.35 | 9,53 | 22.23 | 12.70 | 28,58 | 34,93 | 41,28 | 47,63 | 53,98 | ||

| 600 | 24” | 609,60 | 9,53 | 5,54 | 6.35 | 6.35 | 9,53 | 17.48 | 24.61 | 12.70 | 30,96 | 38,89 | 46.02 | 52,37 | 59,54 | |

| 650 | 26” | 660,40 | 9,53 | 7,92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711,20 | 9,53 | 7,92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762,00 | 9,53 | 6.35 | 7,92 | 7,92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812,80 | 9,53 | 7,92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863,60 | 9,53 | 7,92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914,40 | 9,53 | 7,92 | 12.70 | 19.05 | 12.70 |

Skład chemiczny

| Oceny | C maks | Mn maks | Maks. P | S maks | Si maks | Cr | Ni | Mo |

| 304 | 0,08 | 2.00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0,035 | 2.00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0,08 | 2.00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0,035 | 2.00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Właściwości mechaniczne

| Oceny | Przedmiot | Wytrzymałość na rozciąganie psi | Wydajność psi | Wydłużenie% | Twardość Rockwella |

| 304 | Wyżarzone | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | Wyżarzone I1/8 Trudne | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Wyżarzone | 85000 minut | 35000 minut | 50 minut | 80 minut |

| Wyżarzone | 80000 minut | 30000 minut | 50 minut | 75 minut |

Malowanie i powlekanie:Wyżarzone, wytrawiane, polerowane

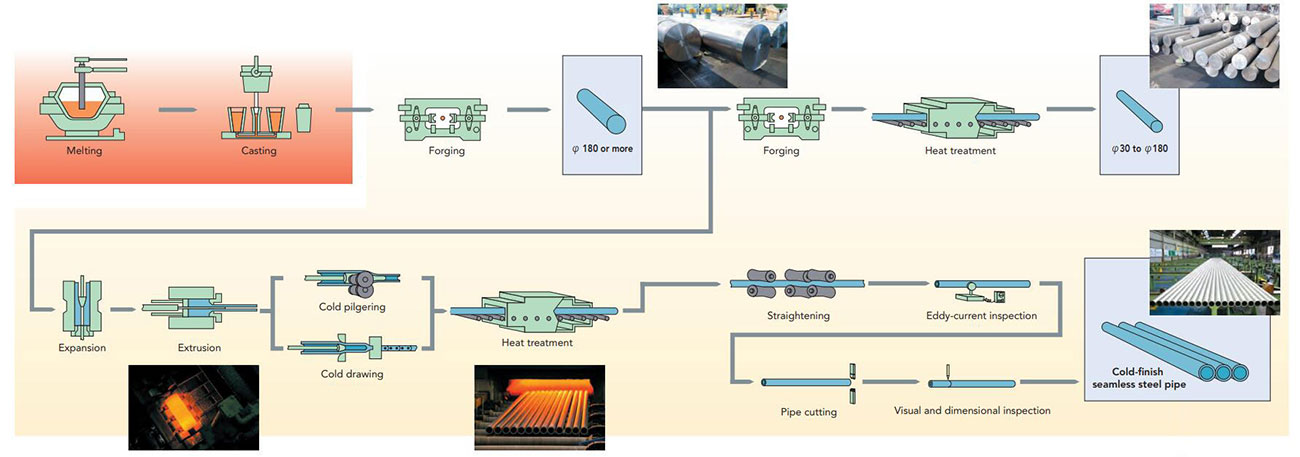

Proces produkcyjny rur stalowych bez szwu