W rurociągach uszczelka to materiał uszczelniający umieszczony pomiędzy kołnierzami łączącymi w celu utworzenia uszczelnienia statycznego, które zapewni szczelność szczelną we wszystkich warunkach pracy. Aby uzyskać szczelne uszczelnienie pomiędzy kołnierzem rury, stosuje się różne rodzaje uszczelek. Podstawową funkcją uszczelek jest uszczelnienie nierówności na każdej powierzchni kołnierza, tak aby nie doszło do wycieku płynu roboczego ze złącza kołnierzowego.

Rodzaje uszczelek stosowanych w danej cieczy zależy od parametrów takich jak

1. Temperatura – materiał uszczelki musi wytrzymywać cały projektowy zakres temperatur cieczy, z którą współpracuje.

2. Ciśnienie – materiał uszczelki musi wytrzymać cały zakres ciśnienia projektowego cieczy, z którą współpracuje.

3. Odporność na korozję – materiał uszczelki nie powinien korodować w kontakcie z płynem, z którym się styka, ani w wyniku narażenia na działanie środowiska.

4. Rodzaje płynów – Materiał uszczelki powinien być w stanie wytrzymać różne rodzaje płynów, jeśli jest zainstalowany w linii, która obsługuje więcej niż jeden rodzaj płynów.

5. Wytrzymałość – Uszczelka musi wytrzymywać wszelkie ruchy, jakie mogą wystąpić na skutek zmian temperatury i ciśnienia.

6. Dostępność – Uszczelka powinna być łatwo dostępna

7. Koszt – Nie należy stosować taniej i zawodnej uszczelki, a jednocześnie nie powinna ona być kosztowna.

Wybór uszczelki

Właściwy dobór uszczelki zależy od następujących czynników.

Zgodność materiału uszczelki z płynem.

Zdolność do wytrzymania ciśnienia i temperatury systemu.

Żywotność uszczelki

Przed dokonaniem wyboru uszczelki ważne jest zrozumienie wymagań konkretnego zastosowania. Uszczelki muszą zachować szczelność przez akceptowalny okres, chroniąc przed wszystkimi zaangażowanymi siłami operacyjnymi. Tam sąosiem ważnych właściwościjakie musi posiadać każda uszczelka, aby to osiągnąć –

1. Nieprzepuszczalność – uszczelka nie powinna być porowata dla uszczelnianego płynu.

2. Ściśliwość – Uszczelka powinna wcisnąć się w niedoskonałości powierzchni uszczelniających kołnierza, aby utworzyć wstępne uszczelnienie.

3. Relaksacja naprężeń (odporność na pełzanie) – Uszczelka nie powinna wykazywać znaczącego płynięcia (pełzania) pod wpływem obciążenia i temperatury. Taki przepływ umożliwi rozluźnienie śrub, zmniejszy naprężenia powierzchniowe uszczelki i spowoduje wyciek.

4. Sprężystość – chociaż zwykle są stabilne, kołnierze w rzeczywistości poruszają się nieznacznie względem siebie pod wpływem cyklicznej temperatury i ciśnienia. Uszczelka powinna być w stanie kompensować takie ruchy.

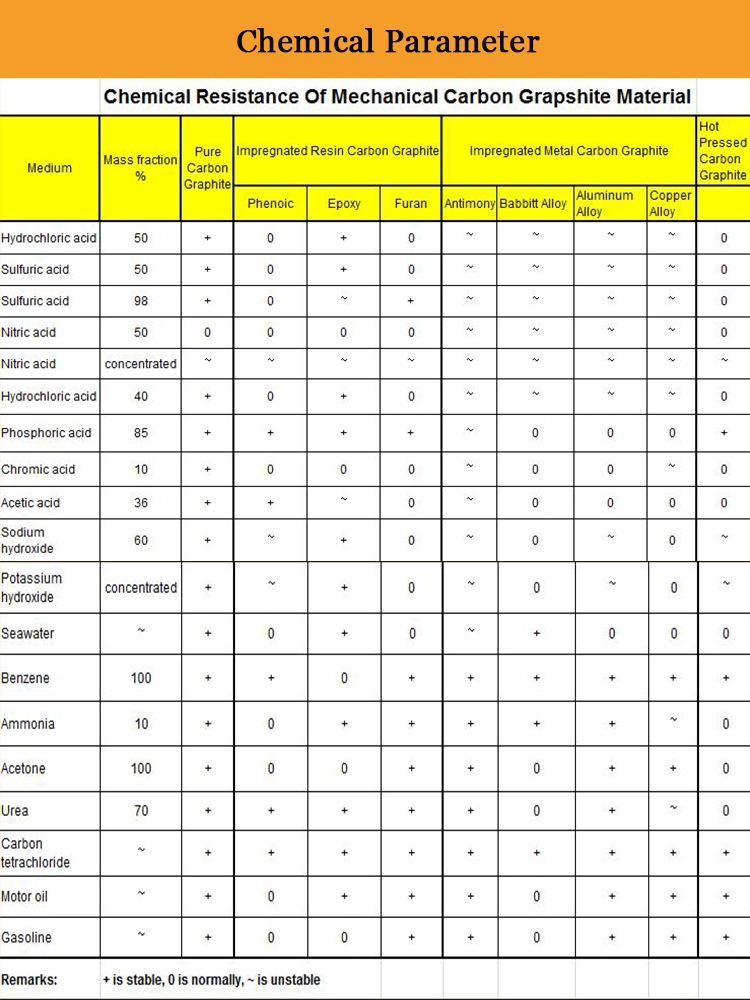

5. Odporność chemiczna – Uszczelka powinna wytrzymać atak chemiczny ze strony medium procesowego. Podobnie sam materiał uszczelki nie może zanieczyszczać medium procesowego.

6. Odporność na temperaturę – Uszczelka powinna być w stanie wytrzymać działanie maksymalnych i minimalnych temperatur zachodzących w procesie oraz zewnętrznych temperatur atmosferycznych.

7. Ochrona przed przywieraniem – uszczelkę należy łatwo zdjąć po użyciu.

8. Ochrona antykorozyjna – Uszczelka nie może powodować korozji powierzchni czołowych kołnierzy.

Rodzaje uszczelek

W rurociągach procesowych stosowane są trzy rodzaje uszczelek.

Niemetalowe

Metaliczny

Złożony

| Niemetalowe | Metaliczny – Uszczelka pierścieniowa | Złożony |

| Uszczelka ze sprężonego włókna nieazbestowego (CNAF) | Uszczelka z owalnym pierścieniem | Uszczelki spiralne |

| Uszczelka PTPE | Uszczelka pierścieniowa ośmiokątna | Uszczelki Comprofile |

| Gumowa uszczelka | Uszczelka z metalowym płaszczem |

Wszystkie materiały są pokryte po obu stronach powłoką zapobiegającą przywieraniu, aby lepiej chronić uszczelkę i samą maszynę.

| Tworzywo | Typ uszczelki | Tworzywo | Aplikacja | Maksymalne krótkotrwałe temperatury |

| NCA-45 | Uszczelka korkowa | Mieszanka korka i gumy syntetycznej | Średnia odporność na olej w większości zastosowań uszczelniających: p Pokrywy zaworów p Miski olejowe p Miski transmisyjne | do 200°C (392°F) |

| CMP-4000 | Uszczelka papierowa | Skompresowany materiał MicroPore, łączący unikalną matrycę z włókien syntetycznych i całkowicie utwardzony kauczuk nitrylowo-butadienowy | Doskonała zdolność i właściwości utrzymywania momentu obrotowego w zastosowaniach OEM i przemysłowych. | do 350°C (650°F) |

| HFL-171 | Uszczelka papierowa | Całkowicie utwardzone spoiwo z kauczuku nitrylowo-butadienowego | Zastosowania ciężkie i przemysłowe: p Silnik wysokoprężny p Przekładnia p Chłodzenie p Rurociągi | do 290°C (550°F) |

| HFL-781 | Uszczelka papierowa | Materiał uszczelki o kontrolowanym pęcznieniu, zawierający styren-butadien i spoiwa z kauczuku naturalnego | Wytrzymałe uszczelnienie olejowe Zastosowanie: p Silnik wysokoprężny p Miski olejowe p Przednie osłony | do 290°C (550°F) |

| M5201 | Uszczelka papierowa | Materiał o dużej gęstości z całkowicie utwardzonym spoiwem z kauczuku nitrylowo-butadienowego | Wytrzymały silnik wysokoprężny Zastosowanie: p Odporność na olej p Odporność na paliwo | do 290°C (550°F) |

| MP-15 | Uszczelka papierowa | MicroPore ze spoiwem nitrylowo-butadienowym | Doskonała zdolność do niskiego nacisku kołnierza i utrzymanie momentu obrotowego śrub w zastosowaniach wymagających dużych obciążeń: p Sprężarki p Silniki Diesla pInni | do 205°C (400°F) |

| N-8092 | Uszczelka papierowa | Wzmocniona celuloza ze spoiwem nitrylowym | Doskonała odporność na zgniatanie przy wysokim ciśnieniu kołnierza do zastosowań w silnikach Diesla i sprężarkach: p Olej p Paliwo p Woda | do 180°C (350°F) |

| PF-4S | Uszczelka papierowa | Włókna syntetyczne, zaawansowane wypełniacze i spoiwa nitrylowo-butadienowe | Różne zastosowania oleju, powietrza i chłodziwa: p Miski olejowe p Przednie osłony p Kolektory dolotowe p Uszczelki tylne | do 290°C (550°F) |

| Tworzywo | Typ uszczelki | Tworzywo | Aplikacja | Maksymalne krótkotrwałe temperatury | |

| RN8011 | Papier | Uszczelka | Materiał z włókien celulozowych o niskiej gęstości, z dużą zawartością wypełniacza gumowego i spoiwem z kauczuku nitrylowo-butadienowego | Doskonałe uszczelnienie przy niskich ciśnieniach kołnierzowych w zastosowaniach związanych z olejem i wodą: Silnik p Uszczelki miski skrzyni biegów Pompy wodne p Pieczęcie środowiskowe | do 180°C (350°F) |

| S-8091 | Papier | Uszczelka | Utwardzany utajony materiał związany styrenem-butadienem ze wzmocnionym włóknem celulozowym | Doskonałe uszczelnienie dla: olej Paliwo p Para niskociśnieniowa | do 180°C (350°F) |

| TS-9016 | Papier | Uszczelka | Całkowicie utwardzone spoiwo z kauczuku styrenowo-butadienowego i mieszanka włókien aramidowych i celulozowych | Zastosowania w oleju i wodzie | do 290°C (550°F) |

| VB-72 | Papier | Uszczelka | MicroPore ze spoiwem nitrylowo-butadienowym | Zastosowania o dużej wytrzymałości: p Korpus zaworu p Zastosowania, w których występują wysokie ciśnienia cieczy i wysokie natężenia przepływu. p Odporność na erozję | do 290°C (550°F) |

| EMC-7201 | Metal | Uszczelka | Struktura kompozytowa z całkowicie utwardzonych okładzin uszczelek związanych butadienem nitrylowym o dużej gęstości, połączonych chemicznie i mechanicznie z rdzeniem stalowym ekspandowanym | Zastosowania połączeń konstrukcyjnych silników wysokoprężnych o wysokiej wydajności: p Obudowa przekładni p Obudowy koła zamachowego p Połączenia hydrauliczne pod wysokim ciśnieniem | |

| HTX-900 7% | Metal | Uszczelka | Pokryty grafitem materiał okładzinowy odporny na wysokie temperatury, chemicznie i mechanicznie stopiony z rozszerzonym stalowym rdzeniem | Zastosowania uszczelniające o wysokiej wytrzymałości, integralności termicznej i działaniu zapobiegającym przywieraniu: p Kolektory wydechowe p Kolektor pKolekcjoner p Uszczelki układu EGR | |

| ML6 | Metal | Uszczelka | Bezazbestowe włókno celulozowe połączone z lateksem nitrylowym i żywicami termoutwardzalnymi | Wysokowydajne, niewytłaczające metalowe uszczelnienie wspornika: Kolektory dolotowe Przekładnia Układ hamulcowy Zastosowania przemysłowe | do 205°C (400°F) |

Czernienie, polerowanie, anodowanie, chromowanie, cynkowanie, niklowanie, barwienie itp.