Sa piping, ang Gasket ay sealing material na inilagay sa pagitan ng connecting flanges upang lumikha ng static seal, na magpapanatili ng leakage proof sealing sa lahat ng operating condition. Iba't ibang uri ng gaskets ang ginagamit para makamit ang leak proof sealing sa pagitan ng pipe flange. Ang pangunahing pag-andar ng mga gasket ay upang i-seal ang mga iregularidad ng bawat mukha ng flange upang walang pagtagas ng service fluid mula sa flange joint.

Ang mga uri ng Gasket na gagamitin sa ibinigay na serbisyo ng likido ay depende sa mga parameter tulad ng

1. Temperatura – Ang materyal ng gasket ay dapat makatiis sa buong hanay ng temperatura ng disenyo ng likidong hinahawakan nito.

2. Presyon - Ang materyal ng gasket ay dapat makatiis sa buong hanay ng presyon ng disenyo ng likidong hinahawakan nito.

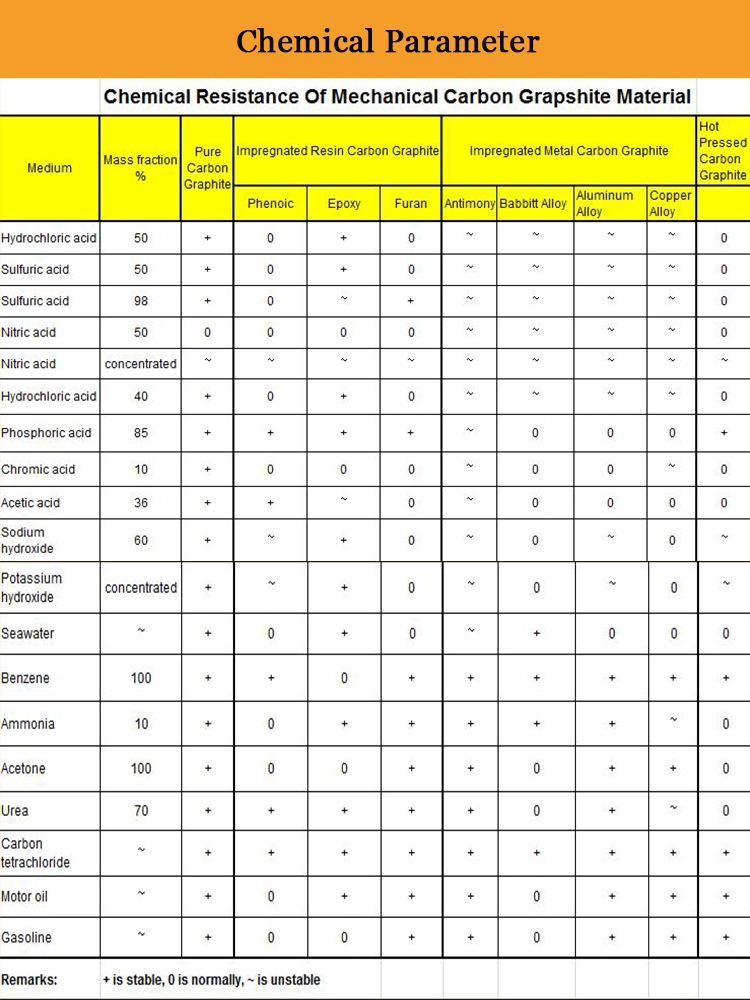

3. Corrosion resistance – Ang gasket material ay hindi dapat na corrode kapag nadikit ito sa likidong hinahawakan nito o sa pagkakalantad sa kapaligiran.

4. Mga uri ng likido - Ang materyal ng gasket ay dapat na may kakayahang makitungo sa iba't ibang uri ng mga likido kung naka-install sa linya na humahawak ng higit sa isang uri ng mga likido.

5. Katatagan - Ang gasket ay dapat na kayang paglabanan ang lahat ng paggalaw na maaaring mangyari dahil sa pagbabago sa temperatura at presyon.

6. Availability - Ang gasket ay dapat na madali

7. Gastos – Ang mura at hindi mapagkakatiwalaang gasket ay hindi dapat gamitin sa parehong oras na hindi ito dapat magastos.

Pagpili ng Gasket

Ang tamang pagpili ng gasket ay depende sa mga sumusunod na salik.

Pagkatugma ng materyal ng gasket sa likido.

Kakayahang makatiis sa pressure-temperatura ng system.

Ang buhay ng serbisyo ng gasket

Mahalagang maunawaan ang mga kinakailangan ng mga partikular na aplikasyon bago gumawa ng pagpili ng gasket. Ang mga gasket ay dapat magpanatili ng selyo para sa isang katanggap-tanggap na panahon laban sa lahat ng mga puwersang nagpapatakbo na kasangkot. meronwalong mahahalagang katangianna dapat taglayin ng anumang gasket upang makamit ito -

1. Impermeability - Ang gasket ay hindi dapat buhaghag sa likidong tinatakan.

2. Compressibility - Ang gasket ay dapat i-compress sa mga imperfections sa flange sealing faces upang lumikha ng paunang seal.

3. Stress relaxation (creep resistance) – Ang gasket ay hindi dapat magpakita ng makabuluhang daloy (creep) kapag sumailalim sa load at temperatura. Ang ganitong daloy ay magpapahintulot sa mga bolts na makapagpahinga, mabawasan ang stress sa ibabaw ng gasket at maging sanhi ng pagtagas.

4. Katatagan - Bagama't normal na stable, ang mga flanges sa katunayan ay bahagyang gumagalaw sa isa't isa sa ilalim ng impluwensya ng temperatura at presyon ng pagbibisikleta. Ang gasket ay dapat na may kakayahang magbayad para sa mga naturang paggalaw.

5. Resistensya sa kemikal - Ang gasket ay dapat makatiis sa pag-atake ng kemikal mula sa daluyan ng proseso na hinahawakan. Gayundin, ang materyal na gasket mismo ay hindi dapat mahawahan ang daluyan ng proseso.

6. Paglaban sa temperatura - Ang gasket ay dapat na makatiis sa mga epekto ng pinakamataas at pinakamababang temperatura sa loob ng proseso at ang mga panlabas na temperatura ng atmospera.

7. Anti-stick - Ang gasket ay kailangang madaling matanggal pagkatapos gamitin.

8. Anti-corrosion – Ang gasket ay hindi dapat maging sanhi ng kaagnasan ng mga flange face.

Mga Uri ng Gasket

Mayroong tatlong uri ng mga gasket na ginagamit sa proseso ng piping.

Non-Metallic

Metallic

Composite

| Non-Metallic | Metallic – Ring Gasket | Composite |

| Compressed Non-Asbestos Fiber Gasket (CNAF) | Oval Ring Gasket | Spiral Wound Gasket |

| PTPE Gasket | Octagonal Ring Gasket | Mga Comprofile Gasket |

| Gasket ng goma | Metal Jacket Gasket |

Ang lahat ng mga materyales ay ginagamot ng isang anti-stick coating sa magkabilang panig upang mas maprotektahan ang gasket at ang makina mismo.

| materyal | Uri ng Gasket | materyal | Aplikasyon | Maximum na Maikling Tagal na Temperatura |

| NCA-45 | Gasket ng Cork | Cork/synthetic rubber timpla | Katamtamang Oil resistance ng karamihan sa Sealing application: p Mga takip ng balbula p Mga Kawali ng Langis p Mga kawali sa paghahatid | hanggang 200°C (392°F) |

| CMP-4000 | Gasket ng Papel | Compressed MicroPore na materyal, pinagsasama ang isang natatanging synthetic fiber matrix at ganap na gumaling na Nitrile Butadiene rubber binder | Napakahusay na kakayahan at mga katangian ng pagpapanatili ng torque para sa OEM at Industrial Applications. | hanggang 350°C (650°F) |

| HFL-171 | Gasket ng Papel | Ganap na gumaling na Nitrile Butadiene rubber binder | Mabigat na tungkulin at Pang-industriya na Aplikasyon: p Diesel engine p Transmission p Refrigeration p Piping | hanggang 290°C (550°F) |

| HFL-781 | Gasket ng Papel | Kinokontrol na swell gasket material na may Styrene Butadiene at natural rubber binders | Aplikasyon ng heavy-duty na oil sealing: p Diesel engine p Mga kawali ng langis p Mga takip sa harap | hanggang 290°C (550°F) |

| M5201 | Gasket ng Papel | High-density na materyal na may fully cured na Nitrile Butadiene rubber binder | Aplikasyon ng Heavy-duty na Diesel engine: p Oil resistance p Paglaban sa gasolina | hanggang 290°C (550°F) |

| MP-15 | Gasket ng Papel | MicroPore na may Nitrile Butadiene binder | Napakahusay na mababang flange pressure na kakayahan at bolt torque retention para sa mga heavy-duty na application: p Mga compressor p Mga makinang diesel p Iba pa | hanggang 205°C (400°F) |

| N-8092 | Gasket ng Papel | Reinforced Cellulose na may Nitrile binder | Napakahusay na resistensya ng crush sa mataas na flange pressure para sa Diesel Engines at Compressor Applications: p Langis p Panggatong p Tubig | hanggang 180°C (350°F) |

| PF-4S | Gasket ng Papel | Mga sintetikong hibla, advanced filler at Nitrile Butadiene binder | Iba't ibang Oil, Air, at Coolant Application: p Mga kawali ng langis p Mga takip sa harap p Intake manifolds p Mga seal sa likuran | hanggang 290°C (550°F) |

| materyal | Uri ng Gasket | materyal | Aplikasyon | Maximum na Maikling Tagal na Temperatura | |

| RN8011 | Papel | Gasket | Mababang density ng Cellulose fiber na materyal na may mataas na nilalaman ng tagapuno ng goma at Nitrile Butadiene rubber binder | Napakahusay na sealing sa mababang flange pressure para sa mga Aplikasyon ng Langis at Tubig: p Makina p Transmission pan gaskets p Mga bomba ng tubig p Mga seal sa kapaligiran | hanggang 180°C (350°F) |

| S-8091 | Papel | Gasket | Latent na lunas na Styrene Butadiene bound material na may reinforced Cellulose fiber | Mahusay na sealing para sa: p Langis p Panggatong p Mababang presyon ng singaw | hanggang 180°C (350°F) |

| TS-9016 | Papel | Gasket | Ganap na gumaling na Styrene Butadiene rubber binder at isang timpla ng Ar- amid at Cellulose fibers | Mga Aplikasyon ng Langis at Tubig | hanggang 290°C (550°F) |

| VB-72 | Papel | Gasket | MicroPore na may Nitrile Butadiene binder | Mga aplikasyon ng mabibigat na tungkulin: p Katawan ng balbula p Mga application na may mataas na presyon ng likido at pagkakalantad sa rate ng daloy p Erosion Resistance | hanggang 290°C (550°F) |

| EMC-7201 | Metal | Gasket | Pinagsamang istraktura ng high-density, ganap na na-cured na Nitrile Butadiene bound gasket facings na kemikal at mekanikal na pinagsama sa isang pinalawak na core ng bakal | High performance Diesel engine structural joint applications: p Gear case p Mga pabahay ng flywheel p High pressure hydraulic joints | |

| HTX-900 7% | Metal | Gasket | Graphite-coated, mataas na temperatura na nakaharap sa materyal na kemikal at mekanikal na pinagsama sa isang pinalawak na core ng bakal | Mataas na lakas, thermal integrity, at anti-stick performance sealing application: p Exhaust manifolds p Header p Kolektor p EGR system gaskets | |

| ML6 | Metal | Gasket | Non-asbestos Cellulose fiber na pinagsama sa Nitrile latex at thermosetting resins | High Performance, non-extruding metal support sealing application: Intake manifolds Transmission Braking system Industrial Application | hanggang 205°C (400°F) |

Pagitim, pagpapakintab, anodize, chrome plating, zinc plating, nickel plating, tinting atbp.