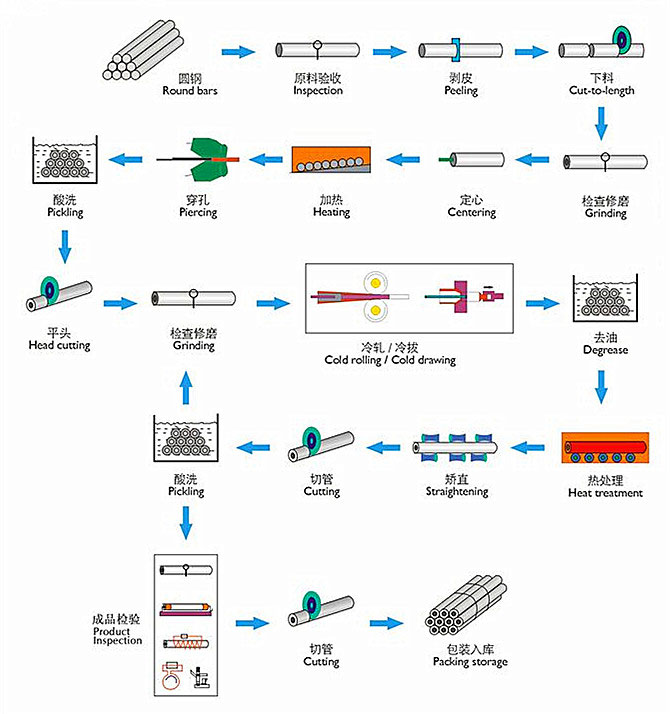

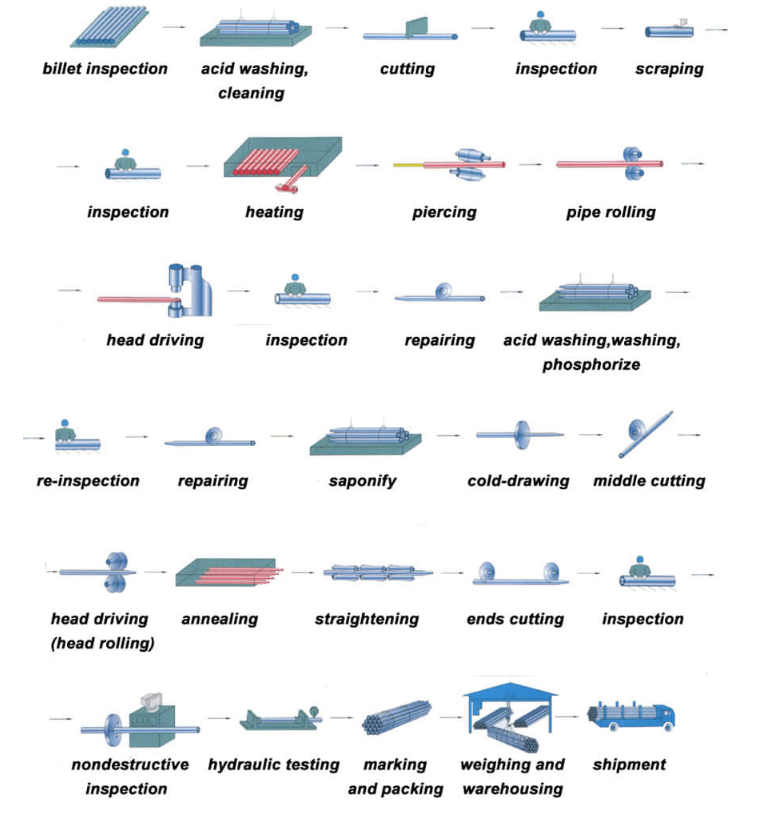

Seamless Steel Pipe na Proseso ng Paggawa

Proseso ng Mandrel Mill

Sa Proseso ng Mandrel Mill, isang solidong bilog (billet) ang ginagamit. Ito ay pinainit sa isang rotary hearth heating furnace at pagkatapos ay tinusok ng isang piercer. Ang pierced billet o hollow shell ay iginugulong ng mandrel mill upang bawasan ang labas na diameter at kapal ng pader na bumubuo ng maraming haba na mother tube. Ang mother tube ay iniinitan muli at higit na binabawasan sa mga tinukoy na sukat ng stretch reducer. Ang tubo ay pagkatapos ay pinalamig, gupitin, ituwid at sasailalim sa mga proseso ng pagtatapos at inspeksyon bago ipadala.

Proseso ng Manner Man Plug Mill

Sa Proseso ng Plug Mill, isang solidong bilog (billet) ang ginagamit. Ito ay pare-parehong pinainit sa rotary hearth heating furnace at pagkatapos ay tinusok ng isang Manner man na piraso. Ang pierced billet o hollow shell ay binawasan ang diameter sa labas at kapal ng pader. Ang pinagsamang tubo ay sabay-sabay na nasunog sa loob at labas ng reeling machine. Ang reeled tube ay sinusukat ng isang sizing mill sa tinukoy na mga sukat. Mula sa hakbang na ito ang tubo ay dumadaan sa straightener. Kinukumpleto ng prosesong ito ang mainit na pagtatrabaho ng tubo. Ang tubo (tinukoy bilang isang mother tube) pagkatapos tapusin at inspeksyon, ay nagiging isang tapos na produkto.

Application ng SMLS Pipe

- Industriya ng Kemikal

- Industriya ng Papel

- Industriya ng pataba

- Industriya ng Tela

- Industriya ng Aviation

- Industriyang Nukleyar

- Industriya ng likido

- Industriya ng Gas at Langis

- Industriya ng Paghahatid ng init

- Serbisyo ng Presyon

- Konstruksyon at Ornamental

- Mga boiler at Heat exchanger

- Mga Piyesa ng Sasakyan

- Medikal na Device

- Industriya ng Pagkain

- Mga Materyales sa Pagbuo

Kami ay isang propesyonal na tagagawa ng Stainless Steel Pipe. Nagbibigay kami ng Stainless Steel Pipe na may iba't ibang laki pati na rin ang mga steel pipe at pipe fitting ng iba't ibang detalye.

Ang aming mga kalamangan:

1. Nangunguna sa China na tagapagbigay ng serbisyo ng produkto at tagaluwas ng bakal na tubo

2. Competitive na presyo at kalidad mula sa aming sariling pabrika

3. One-stop Resource Integration

4. Naipasa ang ISO9001, CE, SGS na sertipikasyon bawat taon

5. Pinakamahusay na serbisyo na may 24 na oras na tugon

6. Mga flexible na paraan ng pagbabayad

7. Malakas na kapasidad ng produksyon

8. Mabilis na paghahatid at karaniwang export packaging

9. OEM/ODM

Mga Tampok ng Seamless Steel Pipe

| Mga uri | Mga gamit |

| Mga Layunin ng Istruktura | Pangkalahatang istraktura at mekanikal |

| Mga Serbisyong Liquid | Petrolyo, gas at iba pang mga likido na nagdadala |

| Mababang at Katamtamang Presyon | Paggawa ng singaw at boiler |

| Serbisyong Hydraulic Pillar | Suporta sa haydroliko |

| Auto Semi-shaft Casing | Auto seam-shaft casing |

| Line Pipe | Paghahatid ng langis at gas |

| Tubing at Casing | Paghahatid ng langis at gas |

| Drill Pipe | Well drilling |

| Geological Drilling Pipe | Geological na pagbabarena |

| Petroleum Cracking Tubes | Mga tubo ng hurno, pagpapalitan ng init |

Dimensyon

| Mga uri ng tubo | Pipe Szie(mm) | Mga pagpaparaya | |

| Hot rolled | OD | <50 | ±0.50mm |

| ≥50 | ±1% | ||

| WT | <4 | ±12.5% | |

| ≥4~20 | +15%, -12.5% | ||

| >20 | ±12.5% | ||

| Malamig na iginuhit | OD | 6~10 | ±0.20mm |

| 10~30 | ±0.40mm | ||

| 30~50 | ±0.45 | ||

| >50 | ±1% | ||

| WT | <1 | ±0.15mm | |

| >1~3 | + 15%, – 10% | ||

| >3 | + 12.5%, – 10% | ||

Mga Kinakailangan sa Komposisyon ng Kemikal

| Pamantayan | Grade | Mga Bahagi ng Kemikal (%) | Mga Katangiang Mekanikal | |||||||||

| c | Si | Mn | P | S | Mo | Cr | V | Tensile Strength(Mpa) | Lakas ng Yield(Mpa) | Pagpahaba (%) | ||

| ASTM A53 | A | ≤0.25 | / | ≤0.95 | ≤0.05 | ≤0.06 | ≤0.15 | ≤0.40 | ≤0.08 | ≥330 | ≥205 | ≥29.5 |

| B | ≤0.30 | / | ≤1.2 | ≤0.05 | ≤0.06 | ≤0.15 | ≤0.40 | ≤0.08 | ≥415 | ≥240 | ≥29.5 | |

| Pamantayan | Grade | Mga Bahagi ng Kemikal(%) | Mga Katangiang Mekanikal | |||||||||

| c | Si | Mn | P | S | Mo | Cr | V | Lakas ng makunat (Mpa) | Lakas ng ani (Mpa) | Pagpahaba(%) | ||

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 | ≥415 | ≥240 | ≥30 |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 | ≥485 | ≥275 | ≥30 | |

| Pamantayan | Grade | Mga Bahagi ng Kemikal(%) | Mga Katangiang Mekanikal | ||||||

| c | Si | Mn | P | S | Tensile Strength(Mpa) | Lakas ng Yield(Mpa) | Pagpahaba(%) | ||

| ASTM A179 | A179 | 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | ≥35 |

| Pamantayan | Grade | Mga Bahagi ng Kemikal(%) | Mga Katangiang Mekanikal | ||||||

| c | Si | Mn | P | S | Tensile Strength(Mpa) | Lakas ng Yield(Mpa) | Pagpahaba(%) | ||

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | ≥35 |

| Pamantayan | Grade | Mga Bahagi ng Kemikal | Tensile Strength(min) | Lakas ng Yield(min) | |||

| C | Mn | P | S | Mpa | Mpa | ||

| API 5L PSL1 | A | 0.22 | 0.90 | 0.030 | 0.030 | 331 | 207 |

| B | 0.28 | 1.20 | 0.030 | 0.030 | 414 | 241 | |

| X42 | 0.28 | 1.30 | 0.030 | 0.030 | 414 | 290 | |

| X46 | 0.28 | 1.40 | 0.030 | 0.030 | 434 | 317 | |

| X52 | 0.28 | 1.40 | 0.030 | 0.030 | 455 | 359 | |

| X56 | 0.28 | 1.40 | 0.030 | 0.030 | 490 | 386 | |

| X60 | 0.28 | 1.40 | 0.030 | 0.030 | 517 | 414 | |

| X65 | 0.28 | 1.40 | 0.030 | 0.030 | 531 | 448 | |

| X70 | 0.28 | 1.40 | 0.030 | 0.030 | 565 | 483 | |

| Pamantayan | Grade | Mga Bahagi ng Kemikal | Tensile Strength(min) | Lakas ng Yield(min) | |||

| C | Mn | P | S | Mpa | Mpa | ||

| API 5L PSL2 | B | 0.24 | 1.20 | 0.025 | 0.015 | 414 | 241 |

| X42 | 0.24 | 1.30 | 0.025 | 0.015 | 414 | 290 | |

| X46 | 0.24 | 1.40 | 0.025 | 0.015 | 434 | 317 | |

| X52 | 0.24 | 1.40 | 0.025 | 0.015 | 455 | 359 | |

| X56 | 0.24 | 1.40 | 0.025 | 0.015 | 490 | 386 | |

| X60 | 0.24 | 1.40 | 0.025 | 0.015 | 517 | 414 | |

| X65 | 0.24 | 1.40 | 0.025 | 0.015 | 531 | 448 | |

| X70 | 0.24 | 1.40 | 0.025 | 0.015 | 565 | 483 | |

| X80 | 0.24 | 1.40 | 0.025 | 0.015 | 621 | 552 | |

Proseso ng paggawa ng Seamless Steel Pipe

Pagpinta at Patong:hubad, bahagyang may langis, itim/pula/dilaw na pagpipinta, zinc/anti-corrosive coating