1. Bend tubing:

Ang pagyuko ng tubo ay ang payong termino para sa mga proseso ng pagbuo ng metal na ginagamit upang permanenteng bumuo ng mga tubo o tubing. Dapat isa-isahin ang pagitan ng form-bound at free form-bending procedure, gayundin sa pagitan ng heat supported at cold forming procedures.

2. Mga Proseso:

Ang pagyuko ng tubo bilang isang proseso ay nagsisimula sa pag-load ng tubo sa isang tubo o pipe bender at pag-clamping nito sa pagitan ng dalawang dies, ang clamping block at ang forming die. Ang tubo ay maluwag ding hawak ng dalawa pang dies, ang wiper die at ang pressure die.

Ang proseso ng pagyuko ng tubo ay kinabibilangan ng paggamit ng mekanikal na puwersa upang itulak ang stock material na tubo o tubing laban sa isang die, na pinipilit ang tubo o tubo na umayon sa hugis ng die. Kadalasan, ang stock tubing ay mahigpit na hawak habang ang dulo ay iniikot at iniikot sa paligid ng die. Iba pang mga paraan ng pagproseso kabilang ang pagtulak ng stock sa pamamagitan ng mga roller na yumuko nito sa isang simpleng kurba.[2] Para sa ilang pagpoproseso ng tube bending, isang mandrel ang inilalagay sa loob ng tubo upang maiwasan ang pagbagsak. Ang tubo ay pinipigilan sa pag-igting ng isang wiper die upang maiwasan ang anumang creasing sa panahon ng stress. Ang wiper die ay kadalasang gawa sa mas malambot na haluang metal tulad ng aluminyo o tanso upang maiwasan ang pagkamot o pagkasira ng materyal na binaluktot.

Pindutin ang baluktot:

Ang press bending ay marahil ang unang proseso ng baluktot na ginamit sa malamig na mga tubo at tubing. Sa prosesong ito ang isang die sa hugis ng liko ay pinindot laban sa tubo na pinipilit ang tubo na magkasya sa hugis ng liko. Dahil ang tubo ay hindi suportado sa loob mayroong ilang pagpapapangit ng hugis ng tubo, na nagreresulta sa isang oval cross section. Ginagamit ang prosesong ito kung saan hindi kinakailangan ang pare-parehong cross section ng pipe. Kahit na ang isang solong die ay maaaring makagawa ng iba't ibang mga hugis, ito ay gumagana lamang para sa isang sukat na tubo at radius.

Rotary draw bending:

Full tooling para sa rotary draw bending

Ang rotary draw bending (RDB) ay isang tumpak na teknolohiya, dahil ito ay yumuyuko gamit ang tooling o "die sets" na may pare-parehong center line radius (CLR), bilang kahalili bilang mean bending radius (Rm).

Roll bending:

Sa proseso ng roll bending, ang pipe, extrusion, o solid ay dinadaanan sa isang serye ng mga roller (karaniwang tatlo) na naglalagay ng pressure sa pipe na unti-unting binabago ang bend radius sa pipe. Ang mga pyramid style roll bender ay may isang gumagalaw na roll, kadalasan ang tuktok na roll. Ang double pinch type roll benders ay may dalawang adjustable roll, kadalasan ang ilalim na roll, at isang fixed top roll. Ang pamamaraang ito ng baluktot ay nagdudulot ng napakakaunting pagpapapangit sa cross section ng pipe. Ang prosesong ito ay angkop sa paggawa ng mga likid ng tubo pati na rin ang mahahabang banayad na liko tulad ng mga ginagamit sa mga sistema ng truss.

Induction bending:

Ang isang induction coil ay inilalagay sa paligid ng isang maliit na seksyon ng pipe sa baluktot na punto. Pagkatapos ay pinainit ito sa induction sa pagitan ng 800 at 2,200 degrees Fahrenheit (430 at 1,200 C). Habang mainit ang tubo, inilalagay ang presyon sa tubo upang yumuko ito. Ang tubo ay maaaring pawiin ng alinman sa hangin o spray ng tubig o palamig laban sa nakapaligid na hangin.

Ang induction bending ay ginagamit upang makabuo ng mga bends para sa malawak na hanay ng mga aplikasyon, tulad ng (manipis na pader) na mga linya ng tubo para sa upstream at down stream at on- at off shore na mga segment ng petrochemical industry, malalaking radius structural parts para sa construction industry, makapal na pader, maikling radius bends para sa power generating industry at city heating system.

Ang malaking bentahe ng induction bending ay:

hindi na kailangan ng mandrel

bend radii at mga anggulo (1°-180°) ay malayang mapipili

napakatumpak na radii ng liko at mga anggulo

ang tumpak na mga spool ng tubo ay madaling makagawa

makabuluhang matitipid ay maaaring makuha sa field welds

malawak na hanay ng mga laki ng tubo ay maaaring tanggapin sa isang makina (1" OD hanggang 80"OD)

mahusay na pagnipis ng pader at mga halaga ng ovality

Para sa Wrought Product (WP) Dimension ay sakop sa

ASME B16.9- na pamantayan para sa Factory-made Wrought Butt-welding Fitting para sa laki na NPS 1⁄₂ hanggang NPS 48” at

At B16.28- na pamantayan para sa Wrought Steel Butt-Welding Short Radius Elbows at Returns para sa laki na NPS 1⁄₂ hanggang NPS 24”

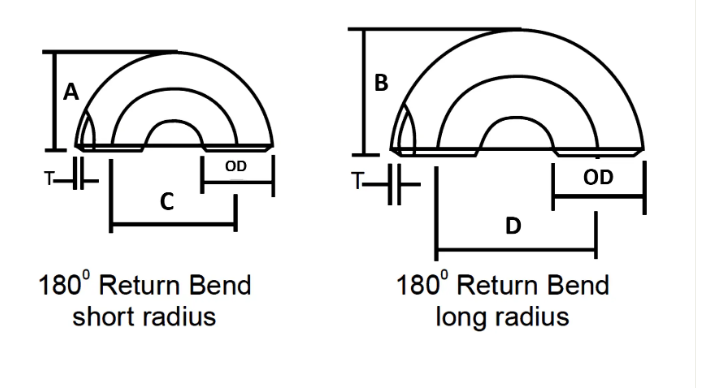

| NOMINAL NA LAKI NG PIPE | LABAS DIAMETER | BACK TO FACE | SENTRO SA SENTRO | ||

| pulgada. | OD | A | B | C | D |

| 1/2 | 21.3 | 48 | – | 76 | – |

| 3/4 | 26.7 | 43 | – | 57 | – |

| 1 | 33.4 | 56 | 41 | 76 | 51 |

| 1 1/4 | 42.2 | 70 | 52 | 95 | 64 |

| 1 1/2 | 48.3 | 83 | 62 | 114 | 76 |

| 2 | 60.3 | 106 | 81 | 152 | 102 |

| 2 1/2 | 73 | 132 | 100 | 191 | 127 |

| 3 | 88.9 | 159 | 121 | 229 | 152 |

| 3 1/2 | 101.6 | 184 | 140 | 267 | 178 |

| 4 | 114.3 | 210 | 159 | 305 | 203 |

| 5 | 141.3 | 262 | 197 | 381 | 254 |

| 6 | 168.3 | 313 | 237 | 457 | 305 |

| 8 | 219.1 | 414 | 313 | 610 | 406 |

| 10 | 273.1 | 518 | 391 | 762 | 508 |

| 12 | 323.9 | 619 | 467 | 914 | 610 |

| 14 | 355.6 | 711 | 533 | 1067 | 711 |

| 16 | 406.4 | 813 | 610 | 1219 | 813 |

| 18 | 457.2 | 914 | 686 | 1372 | 914 |

| 20 | 508 | 1016 | 762 | 1524 | 1016 |

| 22 | 559 | 1118 | 838 | 1676 | 1118 |

| 24 | 610 | 1219 | 914 | 1829 | 1219 |

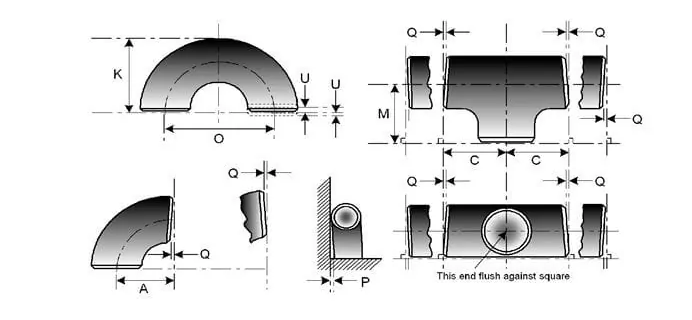

Mga Dimensyon ng Pipe Fittings Tolerance ayon sa ASME B16.9

| NOMINAL NA LAKI NG PIPE | LAHAT NG FITTING | LAHAT NG FITTING | LAHAT NG FITTING | SIKO AT TEES | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | MGA REDUCERS | CAPS |

| NPS | OD sa Bevel (1), (2) | ID sa Katapusan (1), (3), (4) | Kapal ng Pader (3) | Mula sa Gitna hanggang Dulo na Dimensyon A,B,C,M | Center-to-Center O | Bumalik-sa-Mukha K | Alignment ng Ends U | Pangkalahatang Haba H | Pangkalahatang Haba E |

| ½ hanggang 2½ | 0.06 -0.03 | 0.03 | Hindi bababa sa 87.5% ng nominal na kapal | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 3 hanggang 3 ½ | 0.06 | 0.06 | Hindi bababa sa 87.5% ng nominal na kapal | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 4 | 0.06 | 0.06 | Hindi bababa sa 87.5% ng nominal na kapal | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 5 hanggang 8 | 0.09 -0.06 | 0.06 | Hindi bababa sa 87.5% ng nominal na kapal | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 |

| 10 hanggang 18 | 0.16 -0.12 | 0.12 | Hindi bababa sa 87.5% ng nominal na kapal | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 |

| 20 hanggang 24 | 0.25 -0.19 | 0.19 | Hindi bababa sa 87.5% ng nominal na kapal | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 |

| 26 hanggang 30 | 0.25 -0.19 | 0.19 | Hindi bababa sa 87.5% ng nominal na kapal | 0.12 | … | … | … | 0.19 | 0.38 |

| 32 hanggang 48 | 0.25 -0.19 | 0.19 | Hindi bababa sa 87.5% ng nominal na kapal | 0.19 | … | … | … | 0.19 | 0.38 |

Nikel Alloy

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 8825 INCONEL (8250) UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Hindi kinakalawang na asero

ASTM / ASME SA 403 GR WP “S” / “W” / ” WX” 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 347

Duplex Steel

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

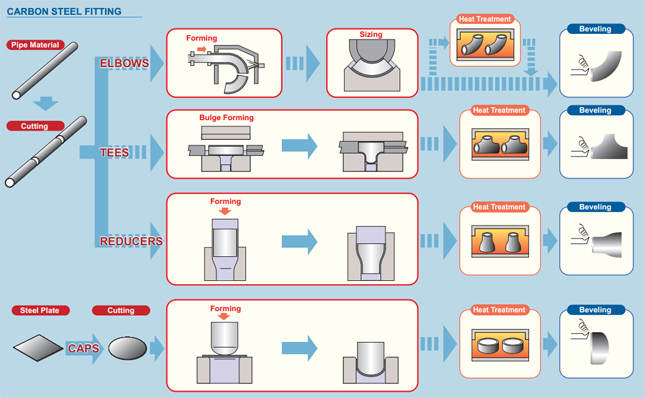

Carbon Steel

ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy na Bakal

ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

| Nilalaman ng Komposisyon ng Kemikal | Mga Katangiang Mekanikal | ||||||||||

| Materyal NO | C | Mn | Si | S | P | Cr | Mo | Ni | lakas ng makunat | lakas ng ani | Pagpahaba |

| A234 WPB | ≤0.3 | 0.29-1.06 | ≥0.1 | ≤0.058 | ≤0.05 | / | / | / | 415-585 | ≥240 | ≥30 |

| A234 WP5 | ≤0.15 | ≤0.6 | ≤0.5 | ≤0.04 | ≤0.03 | 4-6 | 0.44-0.65 | / | 415-585 | ≥205 | ≥20 |

| A403 WP304 | ≤0.08 | ≤2 | ≤1 | ≤0.040 | ≤0.030 | 18-20 | / | 8-11 | ≥515 | ≥205 | ≥30 |

| A403 WP316L | ≤0.03 | ≤2 | ≤1 | ≤0.045 | ≤0.03 | 16-18 | 2-3 | 10-15 | ≥485 | ≥170 | ≥30 |

| WPHY60 | ≤0.20 | 1-1.45 | 0.15-0.4 | ≤0.015 | ≤0.030 | / | / | / | ≥515 | ≥415 | / |

Banayad na Oiling, Black Painting, PE /3PE Anti-corrosion Coating

Mga kinakailangan sa hot induction bend planking

Nakatuon kami sa bawat pamamaraan upang matiyak ang kalidad, ang pakete na karaniwan naming kinukuha ay tabla ang mga steel pipe elbows na may environmental poly bag, at pagkatapos ay sa libreng fumigation na mga wooden case o wooden plate. tumatanggap din kami ng customized na package gaya ng OEM sa pamamagitan ng negosasyon.

- Ang materyal ay dapat na naka-pack na handa para sa pag-export sa paraang nagbibigay-daan sa madaling paghawak at maiwasan ang pinsala, dapat isumite ng vendor ang kanilang karaniwang pamamaraan sa pag-iimpake sa mamimili para sa pag-apruba.

- Ang mga bukas na dulo ng fitting at flanges ay dapat bigyan ng heavy duty plastic protective plugs o caps. Para sa beveled ends, dapat protektahan ng caps ang buong lugar ng bevel.

- Ang water proof barrier material ay dapat gamitin para sa hindi kinakalawang na asero na materyal upang maprotektahan laban sa chlorine attack sa pamamagitan ng pagkakalantad sa tubig-alat na kapaligiran.

- Ang mga bagay na carbon steel at hindi kinakalawang na asero ay hindi pinahihintulutang itabi nang magkasama at dapat na nakaimpake nang hiwalay.