1. Tekuk pipa:

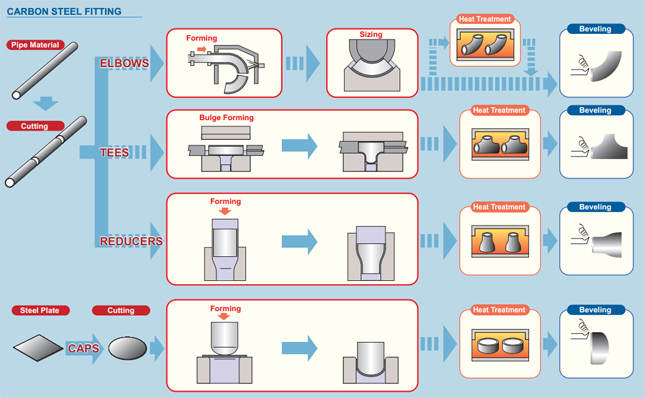

Pembengkokan tabung adalah istilah umum untuk proses pembentukan logam yang digunakan untuk membentuk pipa atau tabung secara permanen. Kita harus membedakan antara prosedur pembengkokan bentuk terikat dan bebas, serta antara prosedur pembentukan yang didukung panas dan dingin.

2. Proses:

Pembengkokan tabung sebagai suatu proses dimulai dengan memasukkan tabung ke dalam tabung atau penyok pipa dan menjepitnya di antara dua cetakan, blok penjepit dan cetakan pembentuk. Tabung juga diikat secara longgar oleh dua cetakan lainnya, yaitu cetakan penghapus dan cetakan tekanan.

Proses pembengkokan tabung melibatkan penggunaan gaya mekanis untuk mendorong pipa atau tabung material stok ke cetakan, memaksa pipa atau tabung agar sesuai dengan bentuk cetakan. Seringkali, pipa stok ditahan dengan kuat di tempatnya sementara ujungnya diputar dan digulung mengelilingi cetakan. Bentuk pemrosesan lainnya termasuk mendorong stok melalui roller yang membengkokkannya menjadi kurva sederhana.[2] Untuk beberapa proses pembengkokan tabung, mandrel ditempatkan di dalam tabung untuk mencegah keruntuhan. Tabung ditahan dalam keadaan tegang oleh wiper die untuk mencegah kusut selama tekanan. Cetakan wiper biasanya terbuat dari bahan paduan yang lebih lembut seperti aluminium atau kuningan untuk menghindari goresan atau kerusakan pada bahan yang ditekuk.

Tekan lentur:

Pembengkokan tekan mungkin merupakan proses pembengkokan pertama yang digunakan pada pipa dan pipa dingin. Dalam proses ini sebuah cetakan berbentuk tikungan ditekan pada pipa sehingga memaksa pipa agar sesuai dengan bentuk tikungan. Karena pipa tidak ditopang secara internal, maka terjadi deformasi pada bentuk pipa, sehingga menghasilkan penampang oval. Proses ini digunakan jika penampang pipa yang konsisten tidak diperlukan. Meskipun satu dadu dapat menghasilkan berbagai bentuk, ia hanya berfungsi untuk satu ukuran tabung dan radius.

Pembengkokan tarik putar:

Perkakas lengkap untuk pembengkokan tarik putar

Rotary draw bending (RDB) adalah teknologi presisi, karena pembengkokannya menggunakan perkakas atau "die set" yang memiliki radius garis tengah (CLR) yang konstan, atau dinyatakan sebagai radius pembengkokan rata-rata (Rm).

Pembengkokan gulungan:

Selama proses pembengkokan gulungan, pipa, ekstrusi, atau benda padat dilewatkan melalui serangkaian rol (biasanya tiga) yang memberikan tekanan pada pipa secara bertahap mengubah radius tikungan dalam pipa. Penyok gulungan gaya piramida memiliki satu gulungan yang bergerak, biasanya gulungan atas. Penyok gulungan tipe penjepit ganda memiliki dua gulungan yang dapat disesuaikan, biasanya gulungan bawah, dan gulungan atas tetap. Metode pembengkokan ini hanya menyebabkan sedikit deformasi pada penampang pipa. Proses ini cocok untuk menghasilkan gulungan pipa serta tikungan lembut yang panjang seperti yang digunakan dalam sistem rangka.

Pembengkokan induksi:

Kumparan induksi ditempatkan di sekitar bagian kecil pipa pada titik tekukan. Kemudian induksi dipanaskan hingga antara 800 dan 2.200 derajat Fahrenheit (430 dan 1.200 C). Saat pipa masih panas, tekanan diberikan pada pipa untuk membengkokkannya. Pipa kemudian dapat dipadamkan dengan semprotan udara atau air atau didinginkan dengan udara sekitar.

Pembengkokan induksi digunakan untuk menghasilkan tikungan untuk berbagai aplikasi, seperti jalur pipa (berdinding tipis) untuk segmen hulu dan hilir serta segmen dalam dan luar pantai industri petrokimia, komponen struktural radius besar untuk industri konstruksi, tikungan berdinding tebal dan radius pendek untuk industri pembangkit listrik dan sistem pemanas kota.

Keuntungan besar dari pembengkokan induksi adalah:

tidak perlu mandrel

jari-jari dan sudut tikungan (1°-180°) dapat dipilih secara bebas

radius dan sudut tikungan yang sangat akurat

gulungan pipa yang akurat dapat dengan mudah diproduksi

penghematan yang signifikan dapat diperoleh pada pengelasan lapangan

berbagai ukuran pipa dapat ditampung dalam satu mesin (1” OD hingga 80”OD)

nilai penipisan dinding dan ovalitas yang sangat baik

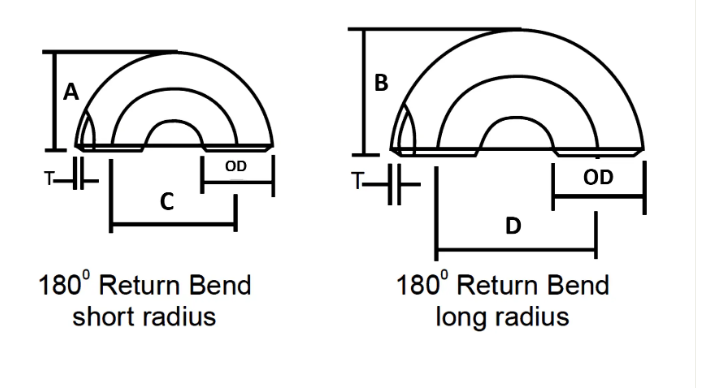

Untuk Dimensi Produk Tempa (WP) tercakup dalam

ASME B16.9- yang merupakan standar untuk Fitting Las Butt Tempa Buatan Pabrik untuk ukuran NPS 1⁄₂ hingga NPS 48” dan

Dan B16.28- yang merupakan standar untuk Siku Radius Pendek Pengelasan Butt Baja Tempa dan Pengembalian untuk ukuran NPS 1⁄₂ hingga NPS 24”

| UKURAN PIPA NOMINAL | DIAMETER LUAR | KEMBALI KE WAJAH | PUSAT KE PUSAT | ||

| Inci. | OD | A | B | C | D |

| 1/2 | 21.3 | 48 | – | 76 | – |

| 3/4 | 26.7 | 43 | – | 57 | – |

| 1 | 33.4 | 56 | 41 | 76 | 51 |

| 1 1/4 | 42.2 | 70 | 52 | 95 | 64 |

| 1 1/2 | 48.3 | 83 | 62 | 114 | 76 |

| 2 | 60.3 | 106 | 81 | 152 | 102 |

| 2 1/2 | 73 | 132 | 100 | 191 | 127 |

| 3 | 88.9 | 159 | 121 | 229 | 152 |

| 3 1/2 | 101.6 | 184 | 140 | 267 | 178 |

| 4 | 114.3 | 210 | 159 | 305 | 203 |

| 5 | 141.3 | 262 | 197 | 381 | 254 |

| 6 | 168.3 | 313 | 237 | 457 | 305 |

| 8 | 219.1 | 414 | 313 | 610 | 406 |

| 10 | 273.1 | 518 | 391 | 762 | 508 |

| 12 | 323.9 | 619 | 467 | 914 | 610 |

| 14 | 355.6 | 711 | 533 | 1067 | 711 |

| 16 | 406.4 | 813 | 610 | 1219 | 813 |

| 18 | 457.2 | 914 | 686 | 1372 | 914 |

| 20 | 508 | 1016 | 762 | 1524 | 1016 |

| 22 | 559 | 1118 | 838 | 1676 | 1118 |

| 24 | 610 | 1219 | 914 | 1829 | 1219 |

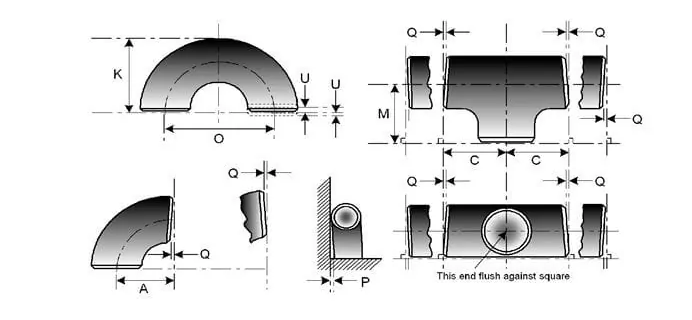

Toleransi Dimensi Kelengkapan Pipa sesuai ASME B16.9

| UKURAN PIPA NOMINAL | SEMUA PERLENGKAPAN | SEMUA PERLENGKAPAN | SEMUA PERLENGKAPAN | SIKU DAN TEES | KETUK KEMBALI 180 DERAJAT | KETUK KEMBALI 180 DERAJAT | KETUK KEMBALI 180 DERAJAT | PEREDUK | CAPS |

| NPC | OD di Bevel (1), (2) | ID di Akhir (1), (3), (4) | Ketebalan Dinding (3) | Dimensi Pusat-ke-Ujung A,B,C,M | Pusat-ke-Pusat O | Kembali ke Wajah K | Penyelarasan Ujung U | Panjang Keseluruhan H | Panjang Keseluruhan E |

| ½ hingga 2½ | 0,06 -0,03 | 0,03 | Tidak kurang dari 87,5% dari ketebalan nominal | 0,06 | 0,25 | 0,25 | 0,03 | 0,06 | 0,12 |

| 3 sampai 3 ½ | 0,06 | 0,06 | Tidak kurang dari 87,5% dari ketebalan nominal | 0,06 | 0,25 | 0,25 | 0,03 | 0,06 | 0,12 |

| 4 | 0,06 | 0,06 | Tidak kurang dari 87,5% dari ketebalan nominal | 0,06 | 0,25 | 0,25 | 0,03 | 0,06 | 0,12 |

| 5 sampai 8 | 0,09 -0,06 | 0,06 | Tidak kurang dari 87,5% dari ketebalan nominal | 0,06 | 0,25 | 0,25 | 0,03 | 0,06 | 0,25 |

| 10 hingga 18 | 0,16 -0,12 | 0,12 | Tidak kurang dari 87,5% dari ketebalan nominal | 0,09 | 0,38 | 0,25 | 0,06 | 0,09 | 0,25 |

| 20 hingga 24 | 0,25 -0,19 | 0,19 | Tidak kurang dari 87,5% dari ketebalan nominal | 0,09 | 0,38 | 0,25 | 0,06 | 0,09 | 0,25 |

| 26 hingga 30 | 0,25 -0,19 | 0,19 | Tidak kurang dari 87,5% dari ketebalan nominal | 0,12 | … | … | … | 0,19 | 0,38 |

| 32 hingga 48 | 0,25 -0,19 | 0,19 | Tidak kurang dari 87,5% dari ketebalan nominal | 0,19 | … | … | … | 0,19 | 0,38 |

Paduan Nikel

ASTM / ASME SB 336 UNS 2200 ( NIKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Baja Tahan Karat

ASTM / ASME SA 403 GR WP “S” / “W” / “WX” 304, 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Baja Dupleks

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

Baja Karbon

ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Baja Paduan

ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

| Kandungan Komposisi Kimia | Sifat Mekanik | ||||||||||

| Bahan TIDAK | C | Mn | Si | S | P | Cr | Mo | Ni | Kekuatan tarik | Kekuatan hasil | Pemanjangan |

| A234WPB | ≤0,3 | 0,29-1,06 | ≥0,1 | ≤0,058 | ≤0,05 | / | / | / | 415-585 | ≥240 | ≥30 |

| A234 WP5 | ≤0,15 | ≤0,6 | ≤0,5 | ≤0,04 | ≤0,03 | 4-6 | 0,44-0,65 | / | 415-585 | ≥205 | ≥20 |

| A403 WP304 | ≤0,08 | ≤2 | ≤1 | ≤0,040 | ≤0,030 | 18-20 | / | 8-11 | ≥515 | ≥205 | ≥30 |

| A403 WP316L | ≤0,03 | ≤2 | ≤1 | ≤0,045 | ≤0,03 | 16-18 | 2-3 | 10-15 | ≥485 | ≥170 | ≥30 |

| WPHY60 | ≤0,20 | 1-1.45 | 0,15-0,4 | ≤0,015 | ≤0,030 | / | / | / | ≥515 | ≥415 | / |

Peminyakan Ringan, Lukisan Hitam, Lapisan Anti Korosi PE /3PE

Persyaratan papan tikungan induksi panas

Kami fokus pada setiap prosedur untuk menjamin kualitas, paket yang biasa kami ambil adalah papan siku pipa baja dengan kantong poli lingkungan, dan kemudian dalam kotak kayu fumigasi gratis atau pelat kayu. Kami juga menerima paket khusus seperti OEM melalui negosiasi.

- Bahan harus dikemas siap untuk diekspor dengan cara yang memudahkan penanganan dan mencegah kerusakan, vendor harus menyerahkan prosedur pengepakan standarnya kepada pembeli untuk mendapatkan persetujuan.

- Ujung fitting dan flensa yang terbuka harus dilengkapi dengan sumbat atau tutup pelindung plastik tugas berat. Untuk ujung yang miring, tutupnya harus melindungi seluruh area bevel.

- Bahan penghalang kedap air harus digunakan untuk bahan baja tahan karat untuk melindungi dari serangan klorin akibat paparan atmosfer air asin.

- Barang baja karbon dan baja tahan karat tidak boleh disimpan bersama dan harus dikemas secara terpisah.