Apa itu Pipa Bor?

Pipa bor, adalah pipa paduan baja atau aluminium berongga, berdinding tipis, yang digunakan pada rig pengeboran. Ini berlubang untuk memungkinkan cairan pengeboran dipompa ke dalam lubang melalui mata bor dan kembali ke annulus. Muncul dalam berbagai ukuran, kekuatan, dan ketebalan dinding, tetapi biasanya panjangnya 27 hingga 32 kaki (Kisaran 2). Ada yang lebih panjang, hingga 45 kaki (Rentang 3).

Bagaimana Cara Bekerja dengan Pipa Pengeboran?

Alat pengeboran dihubungkan dengan batang bor untuk mentransfer tenaga. Bagian rangkaian bor biasanya adalah: bor, kerah bor, pipa bor, stabilisator, konektor khusus dan Kelly. Peran dasar tali bor adalah: (1) mengontrol mata bor; (2) dikenakan WOB; (3) transmisi kekuasaan; (4) mengangkut cairan pengeboran; (5) operasi khusus: ekstrusi semen, penanganan kecelakaan bawah tanah.

Pipa pengeborandilengkapi dengan ulir sekrup untuk menghubungkan rig pengeboran yang terletak di bagian bawah peralatan pengeboran permukaan dan peralatan pabrik atau perangkat outlet bawah. Tujuannya adalah untuk mengebor lumpur pengeboran yang dikirim ke mata bor, dan mengebor dengan cara menaikkan, menurunkan atau memutar saluran keluar bawah. Pipa bor harus mampu menahan tekanan eksternal yang besar, puntiran, tekukan, dan getaran. Dalam proses penambangan dan pemurnian minyak dan gas, pipa bor dapat digunakan berkali-kali.

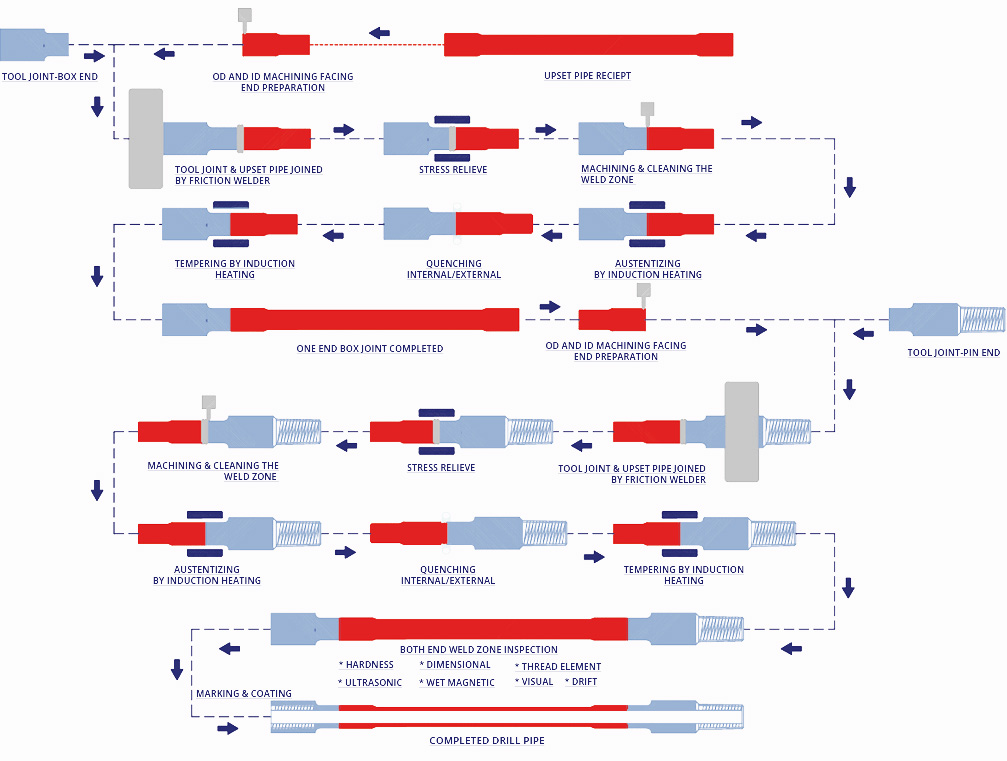

Pipa Bor: Pipa bor meliputi badan pipa dan sambungan perkakas (kotak dan pin) yang dilas menjadi satu, digunakan untuk menghubungkan peralatan permukaan rig pengeboran dan peralatan bawah atau peralatan lubang bawah. Pipa bor dapat menahan tekanan internal dan eksternal yang berat, serta putaran, tekukan, dan getaran yang dapat digunakan lebih dari satu kali selama produksi minyak atau gas.

Pipa bor adalah tabung baja yang dilengkapi dengan ujung berulir yang disebut sambungan perkakas, yang biasanya digunakan dalam tegangan di bagian atas rangkaian bor untuk memompa cairan dan mengirimkan torsi ke mata bor.

Standar:Pipa bor

Nilai:E75, X95, G105, S135

Sabuk sambungan perkakas yang tahan aus:Arnco 100XT, 200XT, 300XT, 400XT

Ipipa bor pelapis internal:TK34, DPC, TC2000, TC3000

Penggunaan:Peledakan tambang, pengeboran sumur air, pengeboran sumur panas bumi, poling depan, proyek penambangan batu bara dan logam nonferrous, dll.

Spesifikasi API 5DPberada di bawah yurisdiksi Komite API untuk Standardisasi Barang Tubular. Tujuan dari spesifikasi ini adalah untuk memberikan standar pipa bor yang sesuai untuk digunakan dalam operasi pengeboran dan produksi.

Proses Khusus Spesifikasi API 5DPuntuk Proses Khusus Pipa Bor adalah operasi akhir yang dilakukan selama pembuatan pipa yang mempengaruhi kepatuhan atribut yang disyaratkan dalam dokumen ini (kecuali kimia dan dimensi). Proses khusus yang berlaku adalah perlakuan panas, pengujian tak rusak, dan, jika berlaku, penyelesaian dingin

Dimensi:

| Penunjukan ukuran | Berat yang dihitung | Penunjukan sambungan alat | Berat yang dihitung | nilai | Ketebalan dinding | Kesal berakhir | ||

| in | 1b/kaki | kg/m | in | mm | ||||

| 2 3/8 | 6.65 | NC26 | 6.26 | 9.32 | EXGS | 0,28 | 7.11 | EU |

| 2 7/8 | 10.4 | NC31 | 9.72 | 14.48 | EXGS | 0,362 | 9.19 | EU |

| 3 1/2 | 13.3 | NC38 | 12.31 | 18.34 | EXGS | 0,368 | 9.35 | EU |

| 3 1/2 | 15.5 | NC38, NC40 | 14.63 | 21.79 | EXGS | 0,449 | 11.4 | EU |

| 4 | 14 | NC40, NC46 | 12.93 | 19.26 | EXGS | 0,33 | 8.38 | IU, UE |

| 4 1/2 | 16.6 | NC46, NC50 | 14.98 | 22.31 | EXGS | 0,337 | 8.56 | UE, IEU |

| 4 1/2 | 20 | NC46, NC50 | 18.69 | 27.84 | EXGS | 0,43 | 10.92 | UE, IEU |

| 5 | 19.5 | NC50, NC52 | 17.93 | 26.71 | EXGS | 0,362 | 9.19 | IEU |

| 5 | 25.6 | NC50,5 1/2FH | 24.03 | 35.79 | EXGS | 0,5 | 12.7 | IEU |

| 5 1/2 | 21.9 | 5 1/2FH | 19.81 | 29.51 | EXGS | 0,361 | 9.17 | IEU |

| 5 1/2 | 24.7 | 5 1/2FH | 22.54 | 33.57 | EXGS | 0,415 | 10.54 | IEU |

| 6 5/8 | 25.2 | 6 5/8FH | 22.19 | 33 | EXGS | 0,33 | 8.387 | IEU |

| 6 5/8 | 27.7 | 6 5/8FH | 24.21 | 41 | EXGS | 0,362 | 9.19 | IEU |

Komposisi Kimia (%):

| Nilai | Komposisi kimia | |

| P | S | |

| E75 | <0,015 | <0,003 |

| X95 | <0,015 | <0,003 |

| G105 | <0,015 | <0,003 |

| S135 | <0,015 | <0,003 |

| Sambungan alat | <0,015 | <0,003 |

Sifat Mekanik:

| Badan pipa | Nilai | Kekuatan hasil | Kekuatan tarik | Pemanjangan | Kekerasan | Uji dampak charpy ukuran penuh (J) | ||||||

| menit | maks | menit | menit | |||||||||

| Psi | MPa | Psi | MPa | Psi | MPa | PBR | HRC | Rata-rata | Lajang | |||

| E75 | 75000 | 517 | 105000 | 724 | 100.000 | 689 | 625000A0.2/ U0.9 | - | - | 80 | 65 | |

| X95 | 95000 | 655 | 125000 | 862 | 105000 | 724 | - | - | 80 | 65 | ||

| G105 | 105000 | 724 | 135000 | 931 | 115000 | 793 | - | - | 80 | 65 | ||

| S135 | 135000 | 931 | 165000 | 1138 | 145000 | 1000 | - | - | 80 | 65 | ||

| Zona las | Sambungan alat | 120000 | 827.4 | - | - | 140000 | 965.3 | =13% | =285 | - | 80 | 65 |

| E75 | 75000 | 517 | - | - | 100.000 | 689 | - | ?37 | 40 | 27 | ||

| X95 | 88000 | 609 | - | - | 103000 | 712 | - | ?37 | 40 | 27 | ||

| G105 | 95000 | 655 | - | - | 105000 | 724 | - | ?37 | 40 | 27 | ||

| S135 | 105000 | 724 | - | - | 115000 | ?37 | 40 | 27 | ||||

Cat Berbasis Air Anti Korosi