Wat is boorpijp?

Boorpijp is een holle, dunwandige buis van staal of aluminiumlegering die wordt gebruikt op booreilanden. Het is hol zodat boorvloeistof door de beitel door het gat kan worden gepompt en terug in de ring kan worden gepompt. Het is verkrijgbaar in verschillende maten, sterktes en wanddiktes, maar is doorgaans 27 tot 32 voet lang (bereik 2). Er bestaan langere lengtes, tot 45 voet (bereik 3).

Hoe te werken met boorpijpen?

Het boorgereedschap is verbonden met een boorstang voor het overbrengen van kracht. De boorkolom bestaat meestal uit: boormachine, boorkragen, boorpijp, stabilisatoren, speciale connectoren en Kelly. De fundamentele rol van de boorkolom is: (1) het besturen van de boor; (2) opgelegde WOB; (3) overdracht van kracht; (4) het transporteren van boorvloeistof; (5) speciale bewerkingen: extrusie van cement, afhandeling van ondergrondse ongevallen.

Boren pijploopt met schroefdraad voor het aansluiten van de boorinstallatie aan de onderkant van oppervlakteboorapparatuur en molenapparatuur of bodemuitlaatapparaat. Het doel is het boren van de boorspoeling die aan de boorbeitel wordt geleverd, en het boren met de vergrotende, verkleinende of roterende bodemuitlaatmiddelen. Boorpijpen moeten bestand zijn tegen grote externe druk, torsie, buiging en trillingen. Bij het mijnbouw- en olie- en gasraffinageproces kan de boorpijp meerdere keren worden gebruikt.

Boor pijp: Boorpijp omvat pijplichaam en gereedschapsverbindingen (doos en pen) die aan elkaar zijn gelast, gebruikt om oppervlakteapparatuur van boorplatforms en bodemapparatuur of bodemgatapparatuur aan te sluiten. Boorpijpen kunnen zware interne en externe druk verdragen, draaien, buigen en trillen, wat meer dan één keer kan worden gebruikt tijdens de olie- of gasproductie.

Boorpijpen zijn stalen buizen die zijn voorzien van uiteinden met schroefdraad, gereedschapsverbindingen genaamd, die gewoonlijk worden gebruikt bij het op spanning brengen in het bovenste deel van de boorkolom om vloeistof te pompen en koppel op de boor over te brengen.

Standaard:Boor pijp

Cijfer:E75, X95, G105, S135

De slijtvaste riem van gereedschapsverbinding:Arnco 100XT, 200XT, 300XT, 400XT

IInterne coating boorpijp:TK34, DPC, TC2000, TC3000

Gebruik:Het vernietigen van mijnen, het boren van waterputten, het boren van geothermische putten, het boren van boorputten, mijnbouwprojecten voor steenkool en non-ferrometalen, enz.

API 5DP-specificatievalt onder de jurisdictie van het API Committee on Standardization ofTubular Goods. Het doel van deze specificatie is het verschaffen van normen voor boorpijpen die geschikt zijn voor gebruik bij boor- en productiewerkzaamheden.

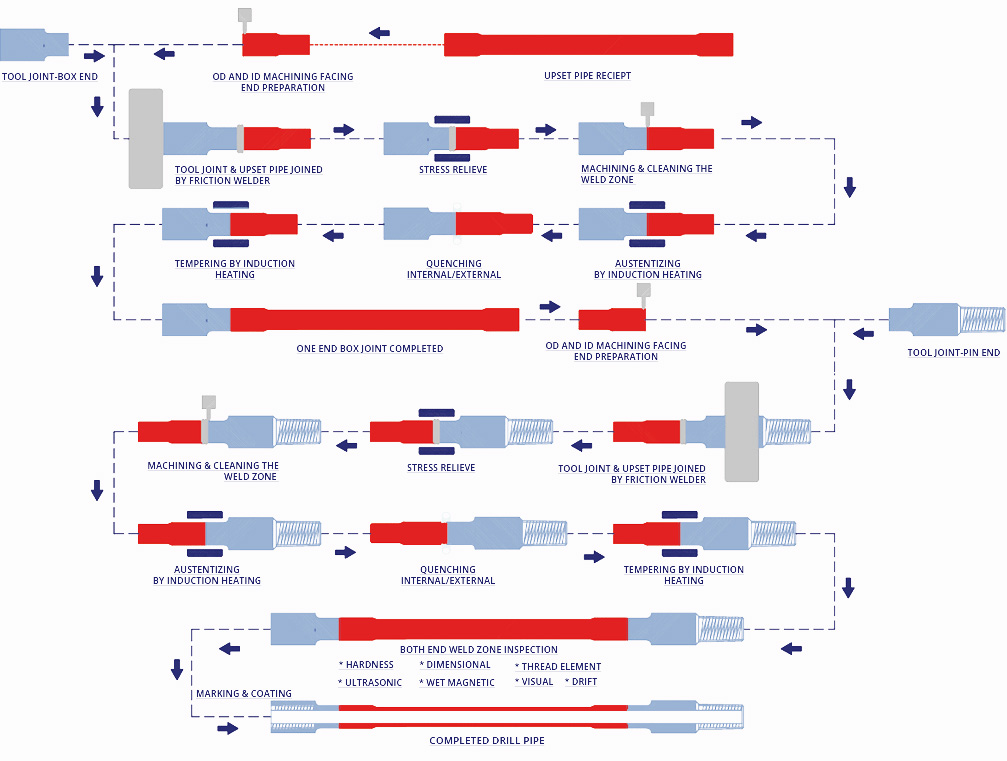

Speciale processen volgens API 5DP-specificatievoor boorpijpen zijn speciale processen de laatste bewerkingen die worden uitgevoerd tijdens de productie van pijpen en die van invloed zijn op de naleving van de kenmerken die in dit document worden vereist (behalve chemie en afmetingen). De toepasselijke speciale processen zijn warmtebehandeling, niet-destructief onderzoek en, indien van toepassing, koude afwerking

Dimensie:

| Maataanduiding | Berekend gewicht | Benaming van gereedschapsverbinding | Berekend gewicht | cijfer | Wanddikte | Boos eindigt | ||

| in | 1b/ft | Kg/m | in | mm | ||||

| 2 3/8 | 6.65 | NC26 | 6.26 | 9.32 | EXGS | 0,28 | 7.11 | EU |

| 2 7/8 | 10.4 | NC31 | 9.72 | 14.48 | EXGS | 0,362 | 9.19 | EU |

| 3 1/2 | 13.3 | NC38 | 12.31 | 18.34 | EXGS | 0,368 | 9.35 | EU |

| 3 1/2 | 15.5 | NC38, NC40 | 14.63 | 21.79 | EXGS | 0,449 | 11.4 | EU |

| 4 | 14 | NC40,NC46 | 12.93 | 19.26 | EXGS | 0,33 | 8.38 | IE, EU |

| 4 1/2 | 16.6 | NC46, NC50 | 14.98 | 22.31 | EXGS | 0,337 | 8.56 | EU,IEU |

| 4 1/2 | 20 | NC46, NC50 | 18.69 | 27.84 | EXGS | 0,43 | 10.92 | EU,IEU |

| 5 | 19.5 | NC50, NC52 | 17.93 | 26.71 | EXGS | 0,362 | 9.19 | IEU |

| 5 | 25.6 | NC50,5 1/2FH | 24.03 | 35,79 | EXGS | 0,5 | 12.7 | IEU |

| 5 1/2 | 21.9 | 5 1/2 FH | 19.81 | 29.51 | EXGS | 0,361 | 9.17 | IEU |

| 5 1/2 | 24.7 | 5 1/2 FH | 22.54 | 33.57 | EXGS | 0,415 | 10.54 | IEU |

| 6 5/8 | 25.2 | 6 5/8FH | 22.19 | 33 | EXGS | 0,33 | 8.387 | IEU |

| 6 5/8 | 27.7 | 6 5/8FH | 24.21 | 41 | EXGS | 0,362 | 9.19 | IEU |

Chemische samenstelling (%):

| Cijfer | Chemische samenstelling | |

| P | S | |

| E75 | <0,015 | <0,003 |

| X95 | <0,015 | <0,003 |

| G105 | <0,015 | <0,003 |

| S135 | <0,015 | <0,003 |

| Gereedschapsverbinding | <0,015 | <0,003 |

Mechanische eigenschappen:

| Pijplichaam | Cijfer | Opbrengststerkte | Treksterkte | Verlenging | Hardheid | Charpy-impacttest op volledige grootte(J) | ||||||

| min | maximaal | min | min | |||||||||

| Psi | MPa | Psi | MPa | Psi | MPa | HBW | HRC | Gemiddeld | Enkel | |||

| E75 | 75000 | 517 | 105000 | 724 | 100000 | 689 | 625000A0,2/ U0,9 | - | - | 80 | 65 | |

| X95 | 95000 | 655 | 125000 | 862 | 105000 | 724 | - | - | 80 | 65 | ||

| G105 | 105000 | 724 | 135000 | 931 | 115000 | 793 | - | - | 80 | 65 | ||

| S135 | 135000 | 931 | 165000 | 1138 | 145000 | 1000 | - | - | 80 | 65 | ||

| Laszone | Gereedschapsverbinding | 120000 | 827,4 | - | - | 140000 | 965,3 | =13% | =285 | - | 80 | 65 |

| E75 | 75000 | 517 | - | - | 100000 | 689 | - | ?37 | 40 | 27 | ||

| X95 | 88000 | 609 | - | - | 103000 | 712 | - | ?37 | 40 | 27 | ||

| G105 | 95000 | 655 | - | - | 105000 | 724 | - | ?37 | 40 | 27 | ||

| S135 | 105000 | 724 | - | - | 115000 | ?37 | 40 | 27 | ||||

Anticorrosieve verf op waterbasis