Sondaj Borusu Nedir?

Sondaj borusu, sondaj kulelerinde kullanılan içi boş, ince duvarlı, çelik veya alüminyum alaşımlı borulardır. Sondaj sıvısının matkap aracılığıyla delikten aşağıya pompalanmasına ve halkanın yukarıya doğru pompalanmasına olanak sağlamak için içi boştur. Çeşitli boyutlarda, güçlerde ve duvar kalınlıklarında gelir, ancak genellikle 27 ila 32 feet uzunluğundadır (Aralık 2). 45 feet'e kadar daha uzun uzunluklar mevcuttur (Aralık 3).

Sondaj Borusu ile Nasıl Çalışılır?

Delme aleti, gücü aktarmak için sondaj çubuğuna bağlanır. Matkap dizisinin genellikle parçaları şunlardır: matkap, matkap yakaları, sondaj borusu, stabilizatörler, özel konektörler ve Kelly. Matkap dizisinin temel rolü şunlardır: (1) matkap ucunu kontrol etmek; (2) empoze edilen WOB; (3) gücün aktarımı; (4) sondaj sıvısının taşınması; (5) özel operasyonlar: çimento ekstrüzyonu, yer altı kazalarının ele alınması.

Sondaj borusuyüzey sondaj ekipmanının ve değirmen ekipmanının veya alt çıkış cihazının alt kısmında bulunan sondaj kulesini bağlamak için vida dişi ile takip ediliyor. Amaç, matkap ucuna verilen sondaj çamurunu delmek, arttırma, azaltma veya döndürmeli alt çıkış vasıtaları ile delmektir. Sondaj boruları büyük dış basınca, bükülmeye, bükülmeye ve titreşime dayanabilmelidir. Madencilik ve petrol ve gaz rafinasyon prosesinde sondaj borusu birden çok kez kullanılabilir.

Sondaj Borusu: Sondaj borusu, sondaj kulesi yüzey ekipmanını ve alt ekipmanı veya alt delik ekipmanını bağlamak için kullanılan, birbirine kaynaklanmış boru gövdesi ve alet bağlantılarını (kutu ve pim) içerir. Sondaj borusu, petrol veya gaz üretimi sırasında birden fazla kez kullanılabilen ağır iç ve dış basınca ve bükülmeye, bükülmeye ve titreşime dayanabilir.

Sondaj boruları, sıvıyı pompalamak ve uca tork iletmek için genellikle sondaj dizisinin üst kısmında gerginlikte kullanılan, alet bağlantıları adı verilen dişli uçlarla donatılmış çelik borulardır.

Standart:Sondaj borusu

Seviye:E75, X95, G105, S135

Alet ekleminin aşınmaya dayanıklı kayışı:Arnco 100XT, 200XT, 300XT, 400XT

Iiç kaplama sondaj borusu:TK34, DPC, TC2000, TC3000

Kullanımı:Maden patlatma, su kuyusu sondajı, jeotermal kuyu sondajı, ön direkleme, kömür ve demir dışı metal madenciliği projeleri vb.

API 5DP ŞartnamesiBoru Şeklindeki Ürünlerin Standardizasyonu API Komitesi'nin yetkisi altındadır. Bu spesifikasyonun amacı sondaj ve üretim operasyonlarında kullanıma uygun sondaj boruları için standartlar sağlamaktır.

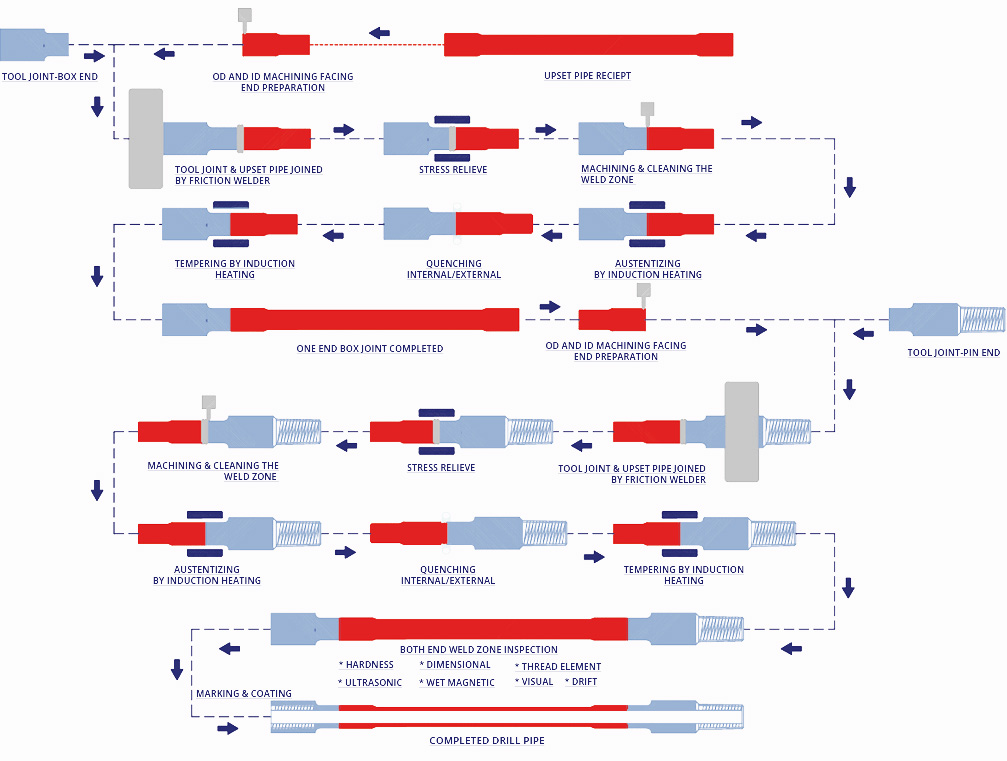

API 5DP Spesifikasyonunun Özel SüreçleriSondaj Borusu için Özel Prosesler, boru üretimi sırasında gerçekleştirilen ve bu belgede gerekli olan nitelik uygunluğunu etkileyen son işlemlerdir (kimya ve boyutlar hariç). Uygulanabilir özel işlemler ısıl işlem, tahribatsız muayene ve varsa soğuk son işlemdir.

Boyut:

| Boyut tanımı | Hesaplanan ağırlık | Takım eklemi tanımı | Hesaplanan ağırlık | seviye | Duvar kalınlığı | Üzgün biter | ||

| in | 1b/ft | kg/m | in | mm | ||||

| 2 3/8 | 6.65 | NC26 | 6.26 | 9.32 | EXGS'ler | 0,28 | 7.11 | EU |

| 2 7/8 | 10.4 | NC31 | 9.72 | 14.48 | EXGS'ler | 0,362 | 9.19 | EU |

| 3 1/2 | 13.3 | NC38 | 12.31 | 18.34 | EXGS'ler | 0,368 | 9.35 | EU |

| 3 1/2 | 15.5 | NC38,NC40 | 14.63 | 21.79 | EXGS'ler | 0,449 | 11.4 | EU |

| 4 | 14 | NC40,NC46 | 12.93 | 19.26 | EXGS'ler | 0,33 | 8.38 | İÜ, AB |

| 4 1/2 | 16.6 | NC46,NC50 | 14.98 | 22.31 | EXGS'ler | 0,337 | 8.56 | AB, IEU |

| 4 1/2 | 20 | NC46,NC50 | 18.69 | 27.84 | EXGS'ler | 0,43 | 10.92 | AB, IEU |

| 5 | 19.5 | NC50,NC52 | 17.93 | 26.71 | EXGS'ler | 0,362 | 9.19 | IEU |

| 5 | 25.6 | NC50,5 1/2FH | 24.03 | 35.79 | EXGS'ler | 0,5 | 12.7 | IEU |

| 5 1/2 | 21.9 | 5 1/2FH | 19.81 | 29.51 | EXGS'ler | 0,361 | 9.17 | IEU |

| 5 1/2 | 24.7 | 5 1/2FH | 22.54 | 33.57 | EXGS'ler | 0,415 | 10.54 | IEU |

| 6 5/8 | 25.2 | 6 5/8FH | 22.19 | 33 | EXGS'ler | 0,33 | 8.387 | IEU |

| 6 5/8 | 27.7 | 6 5/8FH | 24.21 | 41 | EXGS'ler | 0,362 | 9.19 | IEU |

Kimyasal Bileşim(%):

| Seviye | Kimyasal bileşim | |

| P | S | |

| E75 | <0,015 | <0,003 |

| X95 | <0,015 | <0,003 |

| G105 | <0,015 | <0,003 |

| S135 | <0,015 | <0,003 |

| Takım eklemi | <0,015 | <0,003 |

Mekanik Özellikler:

| Boru gövdesi | Seviye | Verim gücü | Çekme mukavemeti | Uzama | Sertlik | Tam boyutlu charpy darbe testi (J) | ||||||

| dk. | maksimum | dk. | dk. | |||||||||

| Psi | MPa | Psi | MPa | Psi | MPa | HBW | sıcak rulo | Ortalama | Bekar | |||

| E75 | 75000 | 517 | 105000 | 724 | 100000 | 689 | 625000A0.2/ U0.9 | - | - | 80 | 65 | |

| X95 | 95000 | 655 | 125000 | 862 | 105000 | 724 | - | - | 80 | 65 | ||

| G105 | 105000 | 724 | 135000 | 931 | 115000 | 793 | - | - | 80 | 65 | ||

| S135 | 135000 | 931 | 165000 | 1138 | 145000 | 1000 | - | - | 80 | 65 | ||

| Kaynak bölgesi | Takım eklemi | 120000 | 827.4 | - | - | 140000 | 965.3 | =%13 | =285 | - | 80 | 65 |

| E75 | 75000 | 517 | - | - | 100000 | 689 | - | ?37 | 40 | 27 | ||

| X95 | 88000 | 609 | - | - | 103000 | 712 | - | ?37 | 40 | 27 | ||

| G105 | 95000 | 655 | - | - | 105000 | 724 | - | ?37 | 40 | 27 | ||

| S135 | 105000 | 724 | - | - | 115000 | ?37 | 40 | 27 | ||||

Korozyon Önleyici Su Bazlı Boya