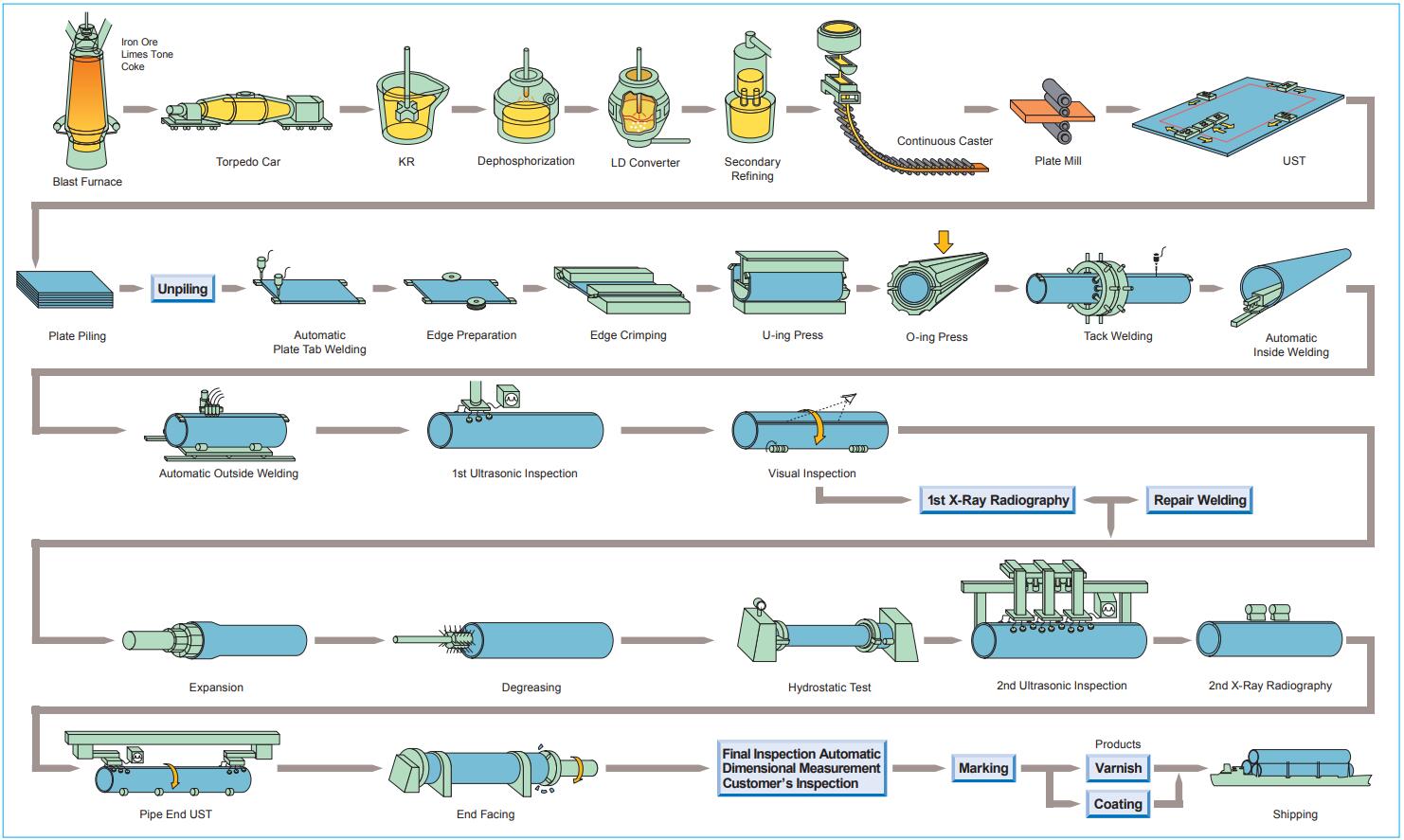

UOE LSAW ÇELİK BORUdeğirmen en ileri teknoloji ve prosese sahiptir, yüksek üretim verimliliğine, istikrarlı ürün kalitesine ulaşır ve eksiksiz denetim ekipmanlarıyla donatılmıştır. UOE fabrikası, U & O şekillendirmeyi benimser; şekillendirilen borular, üç telli beş dahili kaynak istasyonu aracılığıyla içeriden kaynaklanır ve üç telli dört harici kaynak istasyonundan dışarıda kaynak yapılır. Müşterilerin farklı gereksinimlerine uygun olarak, boyutsal doğruluğu artırmak ve artık gerilimi ortadan kaldırmak için kaynaklı boru mekanik veya hidrostatik genleştirme yoluyla genişletilebilir.

Özellikler

Dış Çap 508 mm - 1118 mm (20"- 44")

Duvar Kalınlığı: 6,0-25,4 mm 1/4"-1"

Kalite Standartları: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Uzunluk: 9-12,3 m (30'- 40')

Sınıflar: API 5L A-X90, GB/T9711 L190-L625

JOCE LAHANA ÇELİK BORUÇin'deki büyük çaplı boyuna tozaltı kaynaklı (SAWL) boru üretim hattıdır. Değirmen, eşit olarak dağıtılmış şekillendirme gerilimi, yüksek boyut tekdüzeliği, sonsuz boyut çeşitliliği ve geniş ürün yelpazesi ve yüksek esneklik vb. özellikleri içeren aşamalı bükme işlemini benimser.

Özellikler

Dış Çap: Φ406mm- 1626mm (16" - 64")

Duvar Kalınlığı: 6,0- 75 mm (1/4" - 3")

Kalite Standartları: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Uzunluk: 3-12,5 m (10'- 41')

Sınıflar: API 5L A-X100, GB/T9711 L190-L690

LSAW (Boyuna çift daldırma ark kaynağı) karbonlu çelik boruJCOE veya UOE şekillendirme teknolojisi ile sıcak haddelenmiş çelik levhalardan yapılmış bir tür SAW borudur. JCOE teknolojisi, üretim sırasındaki şekillendirme ve şekillendirme işlemlerinin yanı sıra kaynak sonrası gerçekleştirilen iç ve dış kaynak ve soğuk genleştirmeyi de temsil eder.

LSAW borusudüşük basınçlı sıvı veya yüksek basınçlı petrol veya doğal gazın taşınmasında kullanılır ve ayrıca yapısal desteklerde veya temellerde yaygın olarak kullanılabilir. LSAW tipinin avantajı, maksimum 120 mm'ye kadar daha kalın et kalınlığına sahip borular üretebilmeleridir.

Özellikler:

- Büyük çaplı çelik borular

- Kalın duvarlar

- Yüksek Basınç dayanımı

- Düşük sıcaklık direnci

Testler:

- Kimyasal Bileşen Analizi

- Mekanik Özellikler – Uzama, Akma Dayanımı, Üstün Çekme Dayanımı

- Teknik Özellikler – DWT Testi, Darbe Testi, Şişirme Testi, Yassılaşma Testi

- Röntgen Testi

- Dış Boyut Denetimi

- Hidrostatik Test

- UT Testi

| Dış Çap | Duvar Kalınlığı (mm) | ||||||||||||||||

| İnç | mm | 6.4 | 7.1 | 7.9 | 9.53 | 12.7 | 14.3 | 15.9 | 19.1 | 22.2 | 25.4 | 28.6 | 31.8 | 34.9 | 38.1 | 41.3 | 44.5 |

| 16 | 406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 | 559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 24 | 610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 26 | 660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 28 | 711 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 30 | 762 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 32 | 813 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 34 | 864 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 36 | 914 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 38 | 965 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 40 | 1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 42 | 1067 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 44 | 1118 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 46 | 1168 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 48 | 1219 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 52 | 1321 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 56 | 1422 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 60 | 1524 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 64 | 1626 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Dış Çap ve Et Kalınlığı Toleransı

| Türler | Standart | |||||

| SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| Boru ucu dış çap sapması | ±%0,5D | ±%0,5D | -0,79 mm~+2,38 mm | <±%0,1T | <±%0,1T | ±1,6 mm |

| Duvar kalınlığı | ±%10,0T | D<508mm, ±%12,5T | -8%T~+19,5%T | <-%12,5T | -8%T~+19,5%T | 5,0 mm |

| D>508mm, ±%10,0T | T≥15,0mm, ±1,5mm | |||||

Kimyasal Bileşimi ve Mekanik Özellikler

| Standart | Seviye | Kimyasal Bileşim (maks)% | Mekanik Özellikler(dak) | |||||

| C | Mn | Si | S | P | Akma Dayanımı (Mpa) | Çekme Dayanımı (Mpa) | ||

| GB/T700-2006 | A | 0,22 | 1.4 | 0,35 | 0,050 | 0,045 | 235 | 370 |

| B | 0,2 | 1.4 | 0,35 | 0,045 | 0,045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0,35 | 0,040 | 0,040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0,35 | 0,035 | 0,035 | 235 | 370 | |

| GB/T1591-2009 | A | 0,2 | 1.7 | 0,5 | 0,035 | 0,035 | 345 | 470 |

| B | 0,2 | 1.7 | 0,5 | 0,030 | 0,030 | 345 | 470 | |

| C | 0,2 | 1.7 | 0,5 | 0,030 | 0,030 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | - | 0,035 | 0,035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0,035 | 0,035 | 275 | 410 | |

| S355JR | 0,24 | 1.6 | - | 0,035 | 0,035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0,2 | - | - | 0,050 | 0,050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0,050 | 0,050 | 265 | 410 | |

| ST52-3 | 0,2 | 1.6 | 0,55 | 0,040 | 0,040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0,050 | 0,050 | 235 | 400 |

| SS490 | - | - | - | 0,050 | 0,050 | 275 | 490 | |

| API 5L PSL1 | A | 0,22 | 0,9 | - | 0,03 | 0,03 | 210 | 335 |

| B | 0,26 | 1.2 | - | 0,03 | 0,03 | 245 | 415 | |

| X42 | 0,26 | 1.3 | - | 0,03 | 0,03 | 290 | 415 | |

| X46 | 0,26 | 1.4 | - | 0,03 | 0,03 | 320 | 435 | |

| X52 | 0,26 | 1.4 | - | 0,03 | 0,03 | 360 | 460 | |

| X56 | 0,26 | 1.1 | - | 0,03 | 0,03 | 390 | 490 | |

| X60 | 0,26 | 1.4 | - | 0,03 | 0,03 | 415 | 520 | |

| X65 | 0,26 | 1.45 | - | 0,03 | 0,03 | 450 | 535 | |

| X70 | 0,26 | 1.65 | - | 0,03 | 0,03 | 585 | 570 | |

Hafif yağlı, Sıcak daldırma galvanizli, Elektro galvanizli, Siyah, Çıplak, Vernik kaplama/Pas önleyici yağ, Koruyucu Kaplamalar