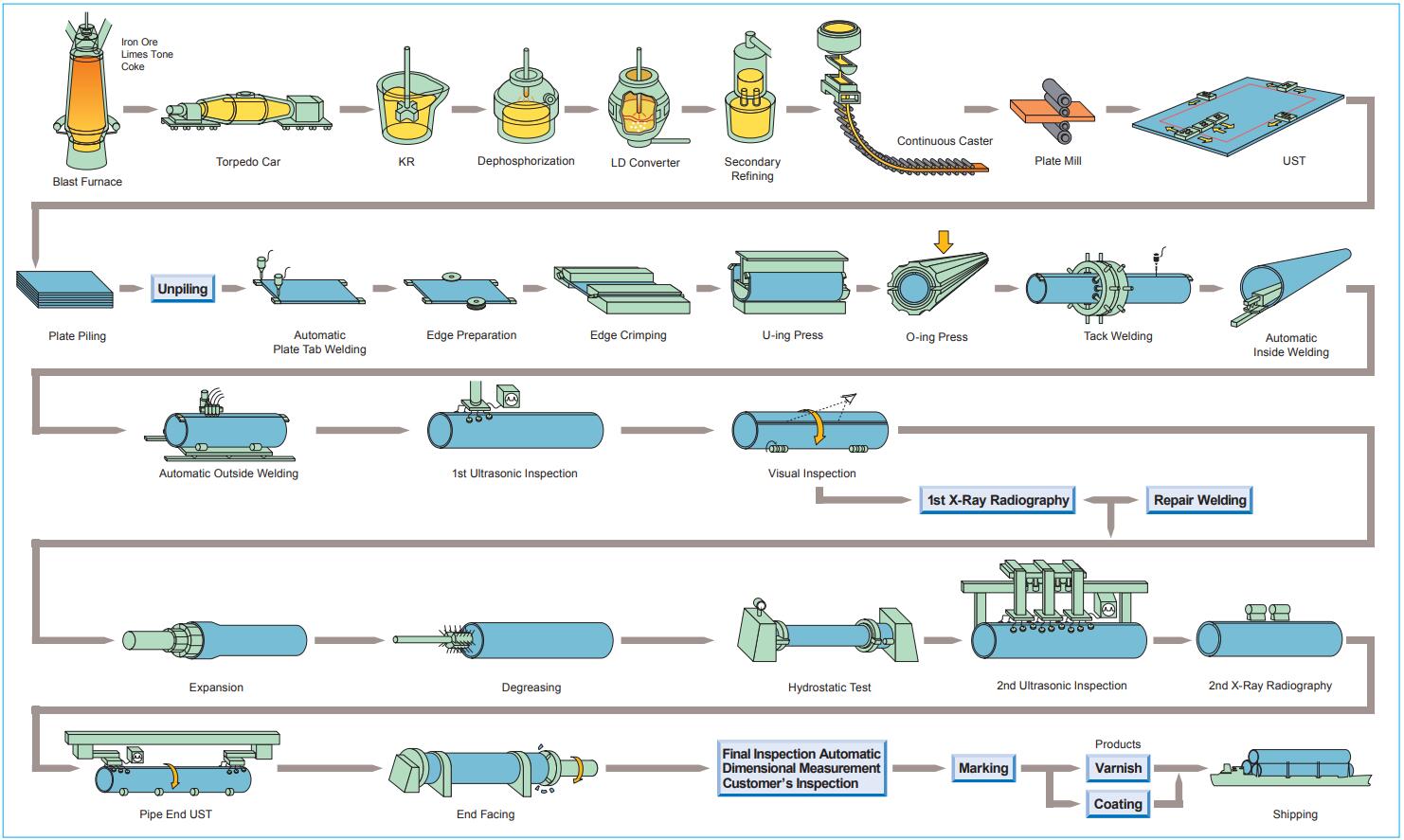

UOE PAIP KELULI LSAWkilang mempunyai teknologi dan proses yang paling canggih, mencapai kecekapan pengeluaran yang tinggi, kualiti produk yang stabil dan dilengkapi dengan peralatan pemeriksaan yang lengkap. Kilang UOE mengamalkan pembentukan U & O, paip yang terbentuk dikimpal di dalam melalui lima stesen kimpalan dalaman dengan tiga wayar, dan dikimpal di luar melalui empat stesen kimpalan luaran dengan tiga wayar. Selaras dengan keperluan pelanggan yang berbeza, paip yang dikimpal boleh dikembangkan sama ada secara mekanikal atau hidrostatik untuk meningkatkan ketepatan dimensi, dan menghapuskan tekanan sisa.

Spesifikasi

Diameter Luar 508mm- 1118mm (20"- 44")

Ketebalan Dinding: 6.0-25.4mm 1/4"-1"

Standard Kualiti: API, DNV, ISO, DEP, EN, ASTM, DIN, BS, JIS, GB, CSA

Panjang: 9-12.3m (30'- 40')

Gred: API 5L A-X90,GB/T9711 L190-L625

PAIP KELULI JOCE SLAWadalah garis pengeluaran paip dikimpal arka tenggelam membujur (SAWL) diameter besar di China. Kilang itu mengamalkan proses lenturan progresif, menampilkan tegasan membentuk teragih sama rata, keseragaman dimensi yang tinggi, variasi saiz tak terhingga&julat poduct lebar, dan fleksibiliti tinggi, dsb.

Spesifikasi

Diameter Luar:Φ406mm- 1626mm (16" - 64")

Ketebalan Dinding:6.0- 75mm (1/4" - 3")

Standard Kualiti: API, DNV, ISO, DEP, EN, ASTM, DIN, BS, JIS, GB, CSA

Panjang:3-12.5m ( 10'- 41' )

Gred:API 5L A-X100, GB/T9711 L190-L690

LSAW (Kimpalan arka tenggelam dua membujur) paip keluli karbonadalah sejenis paip SAW yang diperbuat daripada plat keluli yang digulung panas oleh teknologi pembentukan JCOE atau UOE. Teknologi JCOE mewakili proses membentuk dan membentuk yang terlibat semasa pembuatan serta kimpalan dalam dan luar dan pengembangan sejuk yang dijalankan selepas kimpalan.

paip LSAWdigunakan untuk menyampaikan cecair tekanan rendah atau petroleum tekanan tinggi atau gas asli, dan juga boleh digunakan secara meluas dalam sokongan struktur atau asas. Kelebihan untuk jenis LSAW ialah ia boleh menghasilkan ketebalan dinding paip yang lebih tebal, maksimum hingga 120mm.

ciri-ciri:

- Paip keluli berdiameter besar

- Dinding tebal

- Rintangan Tekanan Tinggi

- Rintangan suhu rendah

Ujian:

- Analisis Komponen Kimia

- Sifat Mekanikal – Pemanjangan, Kekuatan Hasil, Kekuatan Tegangan Muktamad

- Sifat Teknikal – Ujian DWT, Ujian Kesan, Ujian Tiupan, Ujian Merata

- Ujian X-ray

- Pemeriksaan Saiz Luaran

- Ujian Hidrostatik

- Ujian UT

| Diameter Keluar | Ketebalan Dinding (mm) | ||||||||||||||||

| Inci | mm | 6.4 | 7.1 | 7.9 | 9.53 | 12.7 | 14.3 | 15.9 | 19.1 | 22.2 | 25.4 | 28.6 | 31.8 | 34.9 | 38.1 | 41.3 | 44.5 |

| 16 | 406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 | 559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 24 | 610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 26 | 660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 28 | 711 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 30 | 762 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 32 | 813 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 34 | 864 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 36 | 914 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 38 | 965 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 40 | 1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 42 | 1067 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 44 | 1118 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 46 | 1168 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 48 | 1219 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 52 | 1321 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 56 | 1422 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 60 | 1524 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 64 | 1626 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Toleransi Diameter Luar dan Ketebalan Dinding

| Jenis | Standard | |||||

| SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| Sisihan OD hujung tiub | ±0.5%D | ±0.5%D | -0.79mm~+2.38mm | <±0.1%T | <±0.1%T | ±1.6mm |

| Ketebalan dinding | ±10.0%T | D<508mm, ±12.5%T | -8%T~+19.5%T | <-12.5%T | -8%T~+19.5%T | 5.0mm |

| D>508mm, ±10.0%T | T≥15.0mm, ±1.5mm | |||||

Komposisi Kimia dan Sifat Mekanikal

| Standard | Gred | Komposisi Kimia(maks)% | Sifat Mekanikal(min) | |||||

| C | Mn | Si | S | P | Kekuatan Hasil (Mpa) | Kekuatan Tegangan(Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Berminyak ringan, Tergalvani Hot dip, Tergalvani Elektro, Hitam, Bare, Salutan varnis/Minyak anti karat, Salutan Pelindung