Dalam paip, Gasket ialah bahan pengedap yang diletakkan di antara bebibir penyambung untuk mencipta pengedap statik, yang akan mengekalkan pengedap kalis kebocoran dalam semua keadaan operasi. Pelbagai jenis gasket digunakan untuk mencapai kedap kalis kebocoran antara bebibir paip. Fungsi utama gasket adalah untuk menutup ketidakteraturan setiap muka bebibir supaya tidak berlaku kebocoran bendalir servis daripada sambungan bebibir.

Jenis Gasket yang akan digunakan dalam perkhidmatan cecair yang diberikan adalah bergantung kepada parameter seperti

1. Suhu – Bahan gasket mesti menahan keseluruhan julat suhu reka bentuk bendalir yang dikendalikannya.

2. Tekanan – Bahan gasket mesti menahan keseluruhan julat tekanan reka bentuk bendalir yang dikendalikannya.

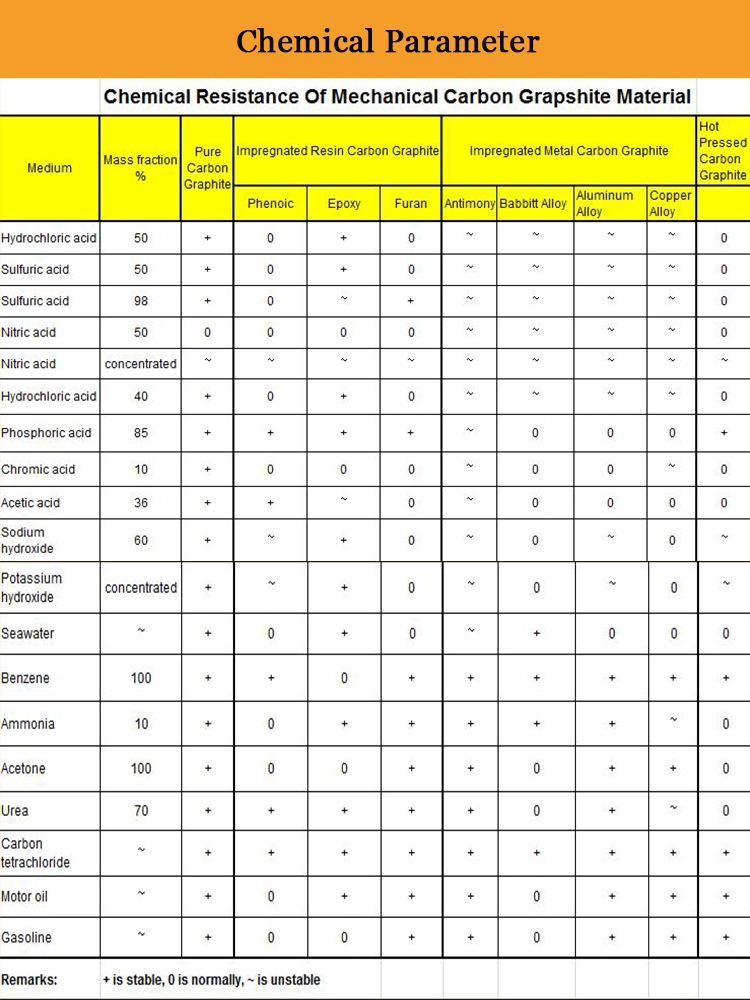

3. Rintangan kakisan – Bahan gasket tidak boleh terhakis apabila ia bersentuhan dengan bendalir yang dikendalikannya atau oleh pendedahan alam sekitar.

4. Jenis bendalir – Bahan gasket harus mampu menangani jenis cecair yang berbeza jika dipasang dalam talian yang mengendalikan lebih daripada satu jenis cecair.

5. Kekukuhan – Gasket mesti mampu menahan semua pergerakan yang mungkin berlaku akibat perubahan suhu dan tekanan.

6. Ketersediaan - Gasket hendaklah mudah

7. Kos – Gasket yang murah dan tidak boleh dipercayai tidak boleh digunakan pada masa yang sama ia tidak sepatutnya mahal.

Pemilihan Gasket

Pemilihan gasket yang betul bergantung kepada faktor berikut.

Keserasian bahan gasket dengan bendalir.

Keupayaan untuk menahan tekanan-suhu sistem.

Hayat perkhidmatan gasket

Adalah penting untuk memahami keperluan aplikasi tertentu sebelum membuat pemilihan gasket. Gasket mesti mengekalkan pengedap untuk tempoh yang boleh diterima terhadap semua kuasa operasi yang terlibat. adalapan sifat pentingyang mesti dimiliki oleh mana-mana gasket untuk mencapai ini -

1. Kebolehtelapan - Gasket tidak boleh berliang kepada bendalir yang dimeteraikan.

2. Kebolehmampatan – Gasket harus memampatkan ke dalam ketidaksempurnaan pada muka pengedap bebibir untuk mencipta pengedap awal.

3. Kelonggaran tegasan (rintangan rayapan) – Gasket seharusnya tidak menunjukkan aliran (creep) yang ketara apabila dikenakan beban dan suhu. Aliran sedemikian akan membolehkan bolt mengendur, mengurangkan tekanan permukaan gasket dan menyebabkan kebocoran.

4. Ketahanan – Walaupun biasanya stabil, bebibir sebenarnya bergerak sedikit berbanding satu sama lain di bawah pengaruh suhu dan tekanan berbasikal. Gasket harus mampu mengimbangi pergerakan tersebut.

5. Rintangan kimia - Gasket harus menahan serangan kimia dari medium proses yang dikendalikan. Begitu juga, bahan gasket itu sendiri tidak boleh mencemarkan medium proses.

6. Rintangan suhu - Gasket harus dapat menahan kesan suhu maksimum dan minimum dalam proses dan suhu atmosfera luaran.

7. Anti-melekat – Gasket hendaklah mudah ditanggalkan selepas digunakan.

8. Anti-karat – Gasket tidak boleh menyebabkan kakisan pada muka bebibir.

Jenis Gasket

Terdapat tiga jenis gasket yang digunakan dalam proses paip.

Bukan Logam

metalik

Komposit

| Bukan Logam | Logam – Gasket Cincin | Komposit |

| Gasket Gentian Bukan Asbestos Mampat (CNAF) | Gasket Cincin Bujur | Gasket Luka Lingkaran |

| Gasket PTPE | Gasket Cincin Oktagonal | Gasket Komprofil |

| Gasket Getah | Gasket Jaket Logam |

Semua bahan dirawat dengan salutan anti-stick pada kedua-dua belah untuk melindungi gasket dan mesin itu sendiri dengan lebih baik.

| bahan | Jenis Gasket | bahan | Permohonan | Suhu Tempoh Pendek Maksimum |

| NCA-45 | Gasket Gabus | Gabus/campuran getah sintetik | Rintangan Minyak Sederhana bagi kebanyakan aplikasi Pengedap: p Penutup Injap p Kuali Minyak p Kuali Penghantaran | sehingga 200°C (392°F) |

| CMP-4000 | Gasket Kertas | Bahan MicroPore termampat, menggabungkan matriks gentian sintetik yang unik dan pengikat getah Nitrile Butadiena yang telah sembuh sepenuhnya | Keupayaan dan sifat pengekalan tork yang sangat baik untuk Aplikasi OEM dan Perindustrian. | sehingga 350°C (650°F) |

| HFL-171 | Gasket Kertas | Pengikat getah Nitrile Butadiena yang telah sembuh sepenuhnya | Tugas berat dan Aplikasi Perindustrian: p Enjin diesel p Penghantaran p Penyejukan p Paip | sehingga 290°C (550°F) |

| HFL-781 | Gasket Kertas | Bahan gasket bengkak terkawal dengan Styrene Butadiene dan pengikat getah asli | Aplikasi pengedap minyak tugas berat: p Enjin diesel p Kuali minyak p Penutup hadapan | sehingga 290°C (550°F) |

| M5201 | Gasket Kertas | Bahan berketumpatan tinggi dengan pengikat getah Nitrile Butadiena yang telah sembuh sepenuhnya | Aplikasi enjin Diesel tugas berat: p Rintangan minyak p Rintangan bahan api | sehingga 290°C (550°F) |

| MP-15 | Gasket Kertas | MicroPore dengan pengikat Nitrile Butadiene | Keupayaan tekanan flange rendah yang sangat baik dan pengekalan tork bolt untuk aplikasi tugas berat: p Pemampat p Enjin diesel p Lain-lain | sehingga 205°C (400°F) |

| N-8092 | Gasket Kertas | Selulosa Bertetulang dengan pengikat Nitril | Rintangan penghancuran yang sangat baik pada tekanan bebibir tinggi untuk Enjin Diesel dan Aplikasi Pemampat: p Minyak p Bahan api p Air | sehingga 180°C (350°F) |

| PF-4S | Gasket Kertas | Gentian sintetik, pengisi lanjutan dan pengikat Nitril Butadiena | Pelbagai Aplikasi Minyak, Udara dan Penyejuk: p Kuali minyak p Penutup hadapan p Manifold pengambilan p Pengedap belakang | sehingga 290°C (550°F) |

| bahan | Jenis Gasket | bahan | Permohonan | Suhu Tempoh Pendek Maksimum | |

| RN8011 | kertas | Gasket | Bahan gentian selulosa berketumpatan rendah dengan kandungan pengisi getah yang tinggi dan pengikat getah Nitril Butadiena | Pengedap yang sangat baik pada tekanan bebibir rendah untuk Aplikasi Minyak dan Air: p Enjin p Gasket kuali penghantaran p Pam air p Pengedap alam sekitar | sehingga 180°C (350°F) |

| S-8091 | kertas | Gasket | Bahan terikat Styrene Butadiene penawar terpendam dengan gentian Selulosa yang diperkukuh | Pengedap yang sangat baik untuk: p Minyak p Bahan api p Stim bertekanan rendah | sehingga 180°C (350°F) |

| TS-9016 | kertas | Gasket | Pengikat getah Styrene Butadiena yang telah sembuh sepenuhnya dan campuran gentian Ar- amid dan Selulosa | Aplikasi Minyak dan Air | sehingga 290°C (550°F) |

| VB-72 | kertas | Gasket | MicroPore dengan pengikat Nitrile Butadiene | Aplikasi tugas berat: p Badan injap p Aplikasi dengan tekanan bendalir tinggi dan pendedahan kadar aliran p Rintangan Hakisan | sehingga 290°C (550°F) |

| EMC-7201 | logam | Gasket | Struktur komposit gasket terikat Nitril Butadiena berketumpatan tinggi yang diawet sepenuhnya secara kimia dan mekanikal dicantumkan kepada teras keluli yang dikembangkan | Aplikasi sambungan struktur enjin Diesel berprestasi tinggi: p Kotak gear p Perumah roda tenaga p Sendi hidraulik tekanan tinggi | |

| HTX-900 7% | logam | Gasket | Bersalut grafit, bahan menghadapi suhu tinggi secara kimia dan mekanikal dicantum kepada teras keluli yang diperluas | Kekuatan tinggi, integriti terma dan aplikasi pengedap prestasi anti-kayu: p Manifold ekzos p Pengepala p Pengumpul p gasket sistem EGR | |

| ML6 | logam | Gasket | Gentian selulosa bukan asbestos digabungkan dengan lateks Nitril dan resin termoset | Aplikasi pengedap sokongan logam berprestasi tinggi, bukan penyemperitan: Manifold masukan Sistem Brek Transmisi Aplikasi Industri | sehingga 205°C (400°F) |

Menghitam, menggilap, anodize, penyaduran krom, penyaduran zink, penyaduran nikel, pewarnaan dll.