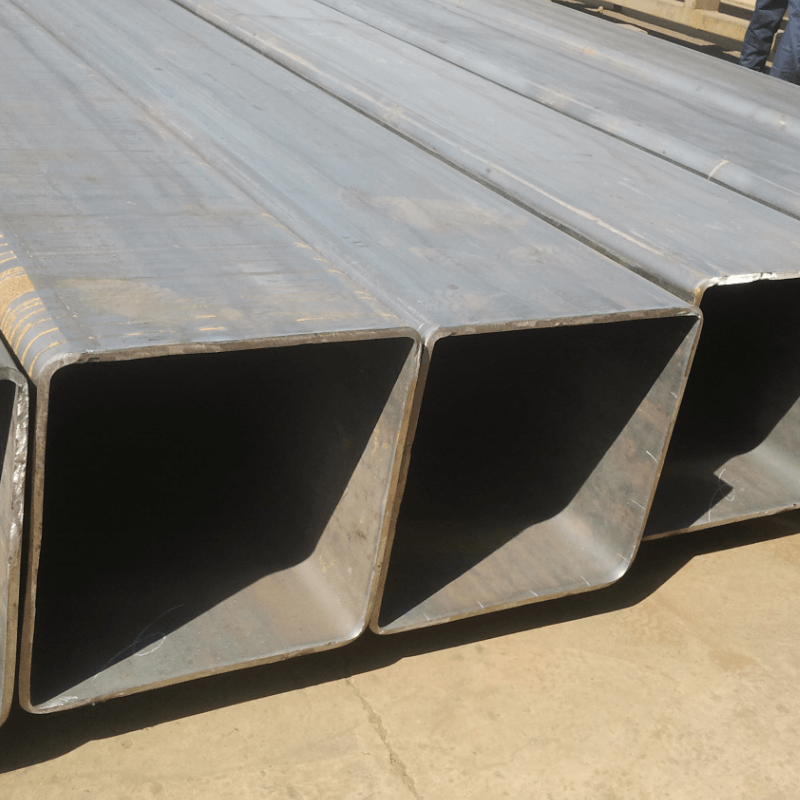

Profilé creux (HSS)est un type de profilé métallique à section creuse. Le terme est principalement utilisé aux États-Unis ou dans d’autres pays qui suivent la terminologie américaine de la construction ou de l’ingénierie.

Les éléments HSS peuvent être des sections circulaires, carrées ou rectangulaires, bien que d'autres formes telles qu'elliptiques soient également disponibles. HSS est uniquement composé d'acier de construction selon le code.

Le HSS est parfois appelé à tort acier de construction creux. Les HSS rectangulaires et carrés sont également communément appelés tube d'acier ou section caissonnée. Les HSS circulaires sont parfois appelés à tort tuyaux en acier, bien que les vrais tuyaux en acier soient en réalité dimensionnés et classés différemment des HSS. (Les dimensions HSS sont basées sur les dimensions extérieures du profilé ; les tuyaux sont également fabriqués selon une tolérance extérieure, bien que selon une norme différente.) Les coins du HSS sont fortement arrondis, ayant un rayon qui est environ deux fois l'épaisseur de la paroi. L'épaisseur de la paroi est uniforme autour de la section.

Au Royaume-Uni ou dans d'autres pays qui suivent la terminologie britannique de la construction ou de l'ingénierie, le terme HSS n'est pas utilisé. Au lieu de cela, les trois formes de base sont référencées CHS, SHS et RHS, étant des sections creuses circulaires, carrées et rectangulaires. En règle générale, ces désignations concernent également les tailles métriques, les dimensions et les tolérances diffèrent donc légèrement de celles du HSS.

Caractéristiques de l'acier à poutre en H

L'acier à poutres métalliques en H est connu pour être incroyablement résistant.

Une poutre en H peut être construite, ce qui signifie qu'elle peut être construite à n'importe quelle taille ou hauteur, ce qui en fait un matériau idéal pour la construction.

Types de poutres en H

Il existe de nombreuses spécifications de produits pour les poutres en H et les méthodes de classification sont les suivantes.

(1) Selon la largeur de la bride du produit, il est divisé en poutres en H à bride large, à bride moyenne et à bride étroite. La largeur de l'aile B de la poutre en H à ailes larges et à ailes moyennes est supérieure ou égale à la hauteur de l'âme H. La largeur de l'aile B de la poutre en H à ailes étroites est approximativement égale à la moitié de la hauteur de l'âme H. La largeur de l'aile de la poutre en H à ailes étroites est approximativement égale à la hauteur de l'âme H.

(2) Selon l'utilisation du produit, il est divisé en poutre en H, colonne de poutre en H, pieu de poutre en H et poutre en H à bride très épaisse. Parfois, les profilés à pieds parallèles et les poutres en T à brides parallèles sont également inclus dans la gamme des poutres en H. Généralement, la poutre en H à bride étroite est utilisée comme matériau de poutre, et la poutre en H à bride large est utilisée comme matériau de colonne, selon laquelle il existe une poutre en H de poutre et une poutre en H de colonne.

(3) Selon la méthode de production, il est divisé en poutre en H soudée et en poutre en H laminée.

(4) Selon les spécifications de taille, il est divisé en poutres en H de grande, moyenne et petite taille. Habituellement, les produits dont la hauteur de bande H est supérieure à 700 mm sont appelés grands, ceux de 300 à 700 mm sont appelés moyens et ceux de moins de 300 mm sont appelés petits. À la fin des années 1990, la plus grande hauteur d'âme de poutre en H au monde était de 1 200 mm et une largeur de bride de 530 mm.

Différence entre les poutres en I en acier et les poutres en H

Qu'est-ce que la poutre en H ?

La poutre en H est une poutre structurelle en acier laminé. C'est incroyablement fort. Il tire son nom du fait qu’il ressemble à un H majuscule sur la section transversale.

Qu'est-ce que I-Beam ?

Une poutre en I a une forme en forme de I. Deux plans horizontaux, appelés brides, sont reliés par un élément vertical, appelé trame, pour former une poutre en I.

Le terme « poutre en I » vient du fait qu’elle ressemble à une lettre majuscule lorsqu’elle est vue en coupe transversale et qu’elle a des bords effilés. Une poutre en I a une section transversale plus haute que large au niveau de la bride.

Quelle est la poutre en H ou la poutre en I la plus solide ?

Poutre en H: La poutre en H a souvent une âme centrale plus épaisse, ce qui la rend plus solide.

poutre en I: Étant donné que les poutres en I ont souvent une âme centrale plus étroite que les poutres en H, elles ne peuvent souvent pas résister à autant de contraintes.

À quoi sert la poutre en H ?

Les poutres en H sont fréquemment utilisées dans la construction de ponts, de grandes remorques et de bâtiments, entre autres. Les poutres en H sont capables de supporter des poids plus lourds que les poutres en I en raison de leur forme de section légèrement différente, de leur âme centrale plus épaisse et de leurs ailes plus larges.

Quel est le but d’une poutre en I ?

En raison de leur excellente utilité, les poutres en I sont la forme préférée pour la construction en acier. Les poutres I sont idéales pour le pliage unidirectionnel parallèlement à l'âme en raison de leur forme. L'âme résiste aux contraintes de cisaillement, mais les ailes horizontales résistent au mouvement de flexion.

Poutre en H et poutre en I : applications

Les poutres en H sont parfaites pour les mezzanines, les plates-formes, les ponts et autres bâtiments résidentiels et commerciaux typiques car elles ont des murs et des brides plus épais.

Dans les constructions résidentielles, des brides larges sont fréquemment utilisées. Les poutres en H sont le matériau choisi pour la charpente de la remorque et du véhicule puisque leurs dimensions intérieures sont cohérentes.

Pour les bâtiments de construction en acier, les ponts et autres structures civiles, les poutres en I sont le choix de forme privilégié en raison de leur résistance accrue aux brides.

Ils sont également utilisés pour construire la charpente et les colonnes de support des trains, des ascenseurs, des plates-formes pour remorques et véhicules, des treuils et des projets de construction résidentielle et commerciale.

Tailles de tubes carrés

| Taille (mm) | Épaisseur de paroi (mm) | Taille (mm) | Épaisseur de paroi (mm) |

| 20*20 | 1.2 | 70*7060*80100*40 | 1.8 |

| 1.3 | 2 | ||

| 1,4-1,5 | 2.2 | ||

| 1.7 | 2.3 | ||

| 1.8 | 2,5-4,0 | ||

| 2 | 4,5-5,0 | ||

| 2.2 | 5,5-5,75 | ||

| 2.3 | 75*7560*90100*50 | 1.8 | |

| 2,5-2,75 | 2 | ||

| 25*2520*30 | 1.2 | 2.2 | |

| 1.3 | 2.3 | ||

| 1,5 | 2,5-4,0 | ||

| 1.7 | 4,5-5,0 | ||

| 1.8 | 5,5-5,75 | ||

| 2 | 80*80100*60100*80120*60 | 2 | |

| 2.3-2.3 | 2.2 | ||

| 2,5-3,0 | 2.3 | ||

| 30*3030*4025*4020*40 | 1 | 2,5-4,0 | |

| 1.2 | 4,5-5,0 | ||

| 1.3 | 5,5-5,75 | ||

| 1,5 | 7,5-7,75 | ||

| 1.7 | 100*100120*80 | 2 | |

| 1.8 | 2.2 | ||

| 2 | 2.3 | ||

| 2.2 | 2,5-5,0 | ||

| 2.3 | 5,5-5,75 | ||

| 2,5*2,75 | 7,5-7,75 | ||

| 3 | 120*120140*80150*100160*80 | 2.5 | |

| 40*4030*5025*50 | 1.2 | 2,75 | |

| 1.3 | 3 | ||

| 1,4-1,5 | 3,25-5,0 | ||

| 1.7 | 5,5-7,0 | ||

| 1.8 | 7,5-7,75 | ||

| 2 | 140*140150*150200*100 | 3,5-4,0 | |

| 2.2-2.3 | 4,5-5,0 | ||

| 2,5-4,0 | 5,25-7,0 | ||

| 50*5060*4030*6040*50 | 1,5 | 7,5-7,75 | |

| 1.7 | 160*160180*180 | 3 | |

| 1.8 | 3.5 | ||

| 2 | 3,75 | ||

| 2.2 | 4.0-5.0 | ||

| 2.3 | 17h25-17h75 | ||

| 2,5*-4,0 | 7,5-7,75 | ||

| 4,25-5,0 | 60*6040*8075*7550*7050*80 | 2.3 | |

| 60*6040*8075*4550*7050*80 | 1,5 | 2,5-4,0 | |

| 1.7 | 4,25-5,0 | ||

| 1.8 | 5,5-5,75 | ||

| 2 | / | ||

| 2.2-2.3 | / |

Tailles de tuyaux rectangulaires

| Taille (mm) | Épaisseur de paroi (mm) | Taille (mm) | Épaisseur de paroi (mm) |

| 20*20 | 1.2 | 70*7060*80100*40 | 1.8 |

| 1.3 | 2 | ||

| 1,4-1,5 | 2.2 | ||

| 1.7 | 2.3 | ||

| 1.8 | 2,5-4,0 | ||

| 2 | 4,5-5,0 | ||

| 2.2 | 5,5-5,75 | ||

| 2.3 | 75*7560*90100*50 | 1.8 | |

| 2,5-2,75 | 2 | ||

| 25*2520*30 | 1.2 | 2.2 | |

| 1.3 | 2.3 | ||

| 1,5 | 2,5-4,0 | ||

| 1.7 | 4,5-5,0 | ||

| 1.8 | 5,5-5,75 | ||

| 2 | 80*80100*60100*80120*60 | 2 | |

| 2.3-2.3 | 2.2 | ||

| 2,5-3,0 | 2.3 | ||

| 30*3030*4025*4020*40 | 1 | 2,5-4,0 | |

| 1.2 | 4,5-5,0 | ||

| 1.3 | 5,5-5,75 | ||

| 1,5 | 7,5-7,75 | ||

| 1.7 | 100*100120*80 | 2 | |

| 1.8 | 2.2 | ||

| 2 | 2.3 | ||

| 2.2 | 2,5-5,0 | ||

| 2.3 | 5,5-5,75 | ||

| 2,5*2,75 | 7,5-7,75 | ||

| 3 | 120*120140*80150*100160*80 | 2.5 | |

| 40*4030*5025*50 | 1.2 | 2,75 | |

| 1.3 | 3 | ||

| 1,4-1,5 | 3,25-5,0 | ||

| 1.7 | 5,5-7,0 | ||

| 1.8 | 7,5-7,75 | ||

| 2 | 140*140150*150200*100 | 3,5-4,0 | |

| 2.2-2.3 | 4,5-5,0 | ||

| 2,5-4,0 | 5,25-7,0 | ||

| 50*5060*4030*6040*50 | 1,5 | 7,5-7,75 | |

| 1.7 | 160*160180*180 | 3 | |

| 1.8 | 3.5 | ||

| 2 | 3,75 | ||

| 2.2 | 4.0-5.0 | ||

| 2.3 | 17h25-17h75 | ||

| 2,5*-4,0 | 7,5-7,75 | ||

| 4,25-5,0 | 60*6040*8075*7550*7050*80 | 2.3 | |

| 60*6040*8075*4550*7050*80 | 1,5 | 2,5-4,0 | |

| 1.7 | 4,25-5,0 | ||

| 1.8 | 5,5-5,75 | ||

| 2 | / | ||

| 2.2-2.3 | / |

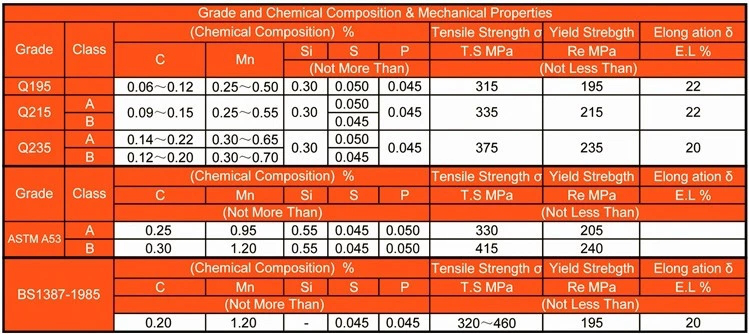

Tubes structurels en acier au carbone soudés et sans soudure formés à froid ASTM A500 en ronds et en formes

EN 10210 Profilés creux structurels finis à chaud en aciers de construction non alliés et à grains fins

EN 10219 Profilés creux structurels soudés formés à froid en aciers non alliés et à grains fins

ASTM A53 utilisé comme acier de construction ou pour la plomberie basse pression

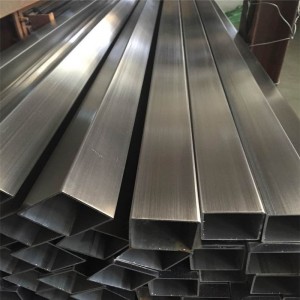

Nu, peinture noire, légèrement huilé

Tube en acier de construction peint

Les SHS (profilés creux carrés) et RHS (profilés creux rectangulaires) peints sont des profilés creux en acier formés à froid à haute résistance qui sont peints avec une couche d'apprêt pour être protégés pendant le stockage et la manipulation.

Les sections structurelles creuses (HSS) sont des longueurs de tubes en acier soudés à haute résistance qui sont utilisées pour les éléments structurels des bâtiments, des structures générales et une variété de produits manufacturés.