ปลอกคอเจาะเป็นเครื่องมือสำคัญที่มีน้ำหนักมากเป็นพิเศษซึ่งใช้ในการรวมน้ำหนักไปที่ดอกสว่านเพื่อสร้างแรงเพียงพอสำหรับดอกสว่านในการหักหินอย่างมีประสิทธิภาพขณะเจาะ ทำจากเหล็กดัดแปลง AISI 4145H และเชื่อมต่อระหว่างท่อเจาะและดอกสว่าน

ปลอกสวมสว่านมีความยาว 30 หรือ 31 ฟุตและตกแต่งเป็นแบบเรียบ (พื้นผิวแบบม้วน) หรือแบบเกลียว ปลอกสวมสว่านแบบเกลียวมีร่องบนพื้นผิวด้านนอก ซึ่งรักษาการไหลของของเหลวที่เจาะรอบๆ ปลอกสวมเพื่อปรับแรงดันให้เท่ากัน และลดการเกาะส่วนต่างของปลอกสวมกับผนังของบ่อน้ำมัน

การเชื่อมต่อคอเจาะของเราเป็นไปตามข้อกำหนดด้านมิติที่ระบุไว้ในข้อมูลจำเพาะ API 7/7-1 และแนวทางที่นำเสนอใน API RP7G ปลอกสวมสว่านยังมาพร้อมกับช่องสลิปและช่องลิฟต์เพื่อการจัดการที่ปลอดภัยและมีประสิทธิภาพ ช่องสลิปและช่องลิฟต์สามารถใช้ร่วมกันหรือแยกกัน และผ่านการตัดเฉือนตามแนวทาง API RP7G เว้นแต่จะระบุไว้เป็นอย่างอื่น

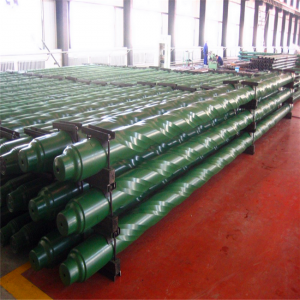

ปลอกคอเจาะแบบไม่มีแม่เหล็ก

สรุปทางเทคนิค

เมื่อคุณเจาะในพื้นที่ใกล้กับขั้วแม่เหล็กของโลก จำเป็นอย่างยิ่งที่จะต้องใช้ปลอกเจาะที่ไม่ใช่แม่เหล็ก ปลอกสวมสว่านแบบไม่มีแม็กของเรามีความแข็งแรงและความแข็ง ในขณะเดียวกันก็ทำให้การอนุมานทางแม่เหล็กเป็นกลาง ปลอกสวมสว่านแบบไม่มีแม็กของเราใช้งานได้กับเครื่องมือร้อยสว่านมาตรฐานและตัวปรับความมั่นคง ผลิตขึ้นตามมาตรฐาน API Spec 7-1 สินค้าคงคลังประกอบด้วย:

(1) เนียน

(2) ดิ้น

(3) เกลียว

(4) ม้าน้อย

เราปฏิบัติต่อ ID วัสดุที่ไม่ใช่แม็กด้วยการดำเนินการเจาะแบบ shot peening เพื่อบีบอัดเส้นผ่านศูนย์กลางด้านใน ซึ่งป้องกันการกัดกร่อนจากความเค้นขณะเจาะในสภาพแวดล้อม H2S

ทนต่อการกัดกร่อนจากความเค้นในสภาพแวดล้อมที่มีก๊าซเปรี้ยว

ใช้งานได้กับเครื่องมือสตริงสว่านมาตรฐานและสเตบิไลเซอร์

เกลียวตามคำขอ

ใช้เพื่อเพิ่มน้ำหนักให้กับดอกสว่านและความแข็งให้กับการประกอบรูด้านล่าง ปลอกเจาะของเราเป็นเครื่องมือในการเจาะรูที่ทรงคุณค่า

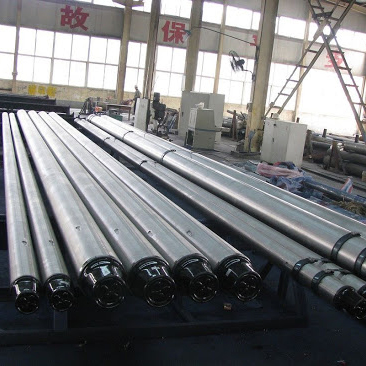

ปลอกสว่านเหล็ก

เพื่อให้คุณเจาะไปในทิศทางที่ถูกต้อง ให้ใช้ปลอกสวมสว่านของเราร่วมกับตัวปรับความมั่นคงของเราเพื่อป้องกันการโก่งงอ ผลิตจากเหล็กโลหะผสมที่ผ่านการดัดแปลงด้วยความร้อน AISI 4145H แนวทางการประกันคุณภาพที่เข้มงวดของเรารับประกันความสมบูรณ์ทางโลหะวิทยาของแท่งแต่ละแท่ง

แท่งคอสว่านของเราเป็นแบบชุดหรือแบบต่อเนื่องด้วยความร้อน และมีทั้งแบบงานเย็นและแบบเคลือบฟอสเฟต

ปลอกคอเจาะแบบไม่มีแม่เหล็ก

| การเชื่อมต่อทั่วไป | OD (นิ้ว) | บัตรประจำตัว (ใน) | น้ำหนักโดยประมาณ (ปอนด์) |

| 2 7/8 เร็ก | 3 1/2 ถึง 3 7/8 | 1 1/4 ถึง 1 3/4 | 760-1114 |

| 3 1/2 reg | 4 1/8 ถึง 4 1/2 | 1 1/4 ถึง 2 1/4 | 989-1490 |

| 3 1/2 ถ้า NC38 | 4 3/4 ถึง 5 1/2 | 1 3/4 ถึง 2 13/16 | 1350-2250 |

| 4 FH NC40 | 5 ถึง 6 | 1 3/4 ถึง 2 13/16 | 1552-2726 |

| 4 1/2 เอฟเอช | 5 1/2 ถึง 6 1/2 | 2 ถึง 3 | 1759-3166 |

| 4 1/2 สูง NC46 | 5 3/4 ถึง 6 3/4 | 2 1/4 ถึง 3 | 1992-3352 |

| 4 1/2 ถ้า NC50 | 6 1/4 ถึง 7 1/2 | 2 1/4 ถึง 3 1/4 | 2359-4237 |

| 5 1/2 FH NC56 | 7 ถึง 7 3/4 | 2 1/4 ถึง 3 1/4 | 3182-4552 |

| 6 5/8 เร็ก | 7 1/4 ถึง 8 | 2 1/2 ถึง 3 1/4 | 3476-4780 |

| 6 5/8 เอฟเอช | 7 1/2 ถึง 8 1/4 | 2 1/2 ถึง 3 1/4 | 3782-5116 |

| 7 5/8 เร็ก | 8 1/2 ถึง 9 1/2 | 2 1/2 ถึง 3 3/4 | 4816-6953 |

ปลอกสว่านเหล็ก

| OD (นิ้ว) | บัตรประจำตัว (ใน) | น้ำหนักในอากาศ (ปอนด์) | หน่วยน้ำหนัก (ปอนด์/ฟุต) | การเชื่อมต่อปลายมาตรฐาน |

| 3 1/2 | 1 1/2 | 826.8 | 26.7 | NC-26 ถึง 35 |

| 4 1/8 | 2 | 1,076.2 | 34 | NC-31 ถึง 41 |

| 4 3/4 | 2 1/4 | 1447.0 | 46.7 | NC-38 ถึง 47 |

| 5 | 2 1/4 | 1648.5 | 53.2 | NC-38 ถึง 50 |

| 6 | 2 1/4 | 2558.0 | 82.5 | NC-44 ถึง 60 |

| 6 | 2 13/59 | 2322.3 | 74.9 | NC-44 ถึง 60 |

| 6 1/4 | 2 1/4 | 2811.2 | 90.7 | NC-44 ถึง 62 |

| 6 1/4 | 2 13/59 | 2575.6 | 83.1 | NC-46 ถึง 65 |

| 6 1/2 | 2 1/4 | 3074.8 | 99.2 | NC-46 ถึง 65 |

| 6 1/2 | 2 13/59 | 2839.1 | 91.6 | NC-46 ถึง 65 |

| 6 3/4 | 2 1/4 | 3348.7 | 108.0 | NC-46 ถึง 67 |

| 7 | 2 1/4 | 3632.9 | 117.2 | NC-50 ถึง 70 |

| 7 | 2 13/59 | 3397.2 | 109.6 | NC-50 ถึง 70 |

| 7 1/4 | 2 13/59 | 3691.8 | 119.1 | NC-50 ถึง 72 |

| 8 | 2 13/59 | 4637.5 | 149.6 | 6 5/8 ปกติ |

| 8 1/4 | 2 13/59 | 4973.4 | 160.4 | 6 5/8 ปกติ |

| 9 1/2* | 3 | 6718.0 | 216.7 | 7 5/8 ปกติ |

| 9 3/4* | 3 | 7116.0 | 229.5 | 7 5/8 ปกติ |

| 11* | 3 | 9260.6 | 298.7 | 8 5/8 ปกติ |

เส้นผ่านศูนย์กลางของช่องสลิปและลิฟต์ที่แนะนำสำหรับคอสว่าน

| มาตรฐาน | ตัวเลข | OD | ID | ความยาว | น้ำหนัก | การดัดแบบทั่วไป |

| SY5144-2007/API7-1 | นอร์ทแคโรไลนา 23-31 | 3-1/8 | 1-1/4 | 30 | 22 | 2.57:1 |

| เอ็นซี 26-35 (2-3/8 ถ้า) | 3-1/2 | 1-1/2 | 30 | 27 | 2.42:1 | |

| เอ็นซี 31-41 (2-7/8 ถ้า) | 4-1/8 | 2 | 30 หรือ 31 | 34 | 2.43:1 | |

| นอร์ทแคโรไลนา 35-47 | 4-3 /4 | 2 | 30 หรือ 31 | 47 | 2.58:1 | |

| เอ็นซี 38-50 (3-1/2 ถ้า) | 5 | 2-1/4 | 30 หรือ 31 | 54 | 2.38:1 | |

| นอร์ทแคโรไลนา 44-60 | 6 | 2-1/4 | 30 หรือ 31 | 83 | 2.49:1 | |

| นอร์ทแคโรไลนา 44-60 | 6 | 2-13 /59 | 30 หรือ 31 | 76 | 2.84:1 | |

| วธ.44-62 | 6-1/4 | 2-1/4 | 30 หรือ 31 | 91 | 2.91:1 | |

| เอ็นซี 46-62 (4 ไอเอฟ) | 6-1/4 | 2-13 /59 | 30 หรือ 31 | 84 | 2.63:1 | |

| เอ็นซี 46-65 (4 ไอเอฟ) | 6-1/2 | 2-1/4 | 30 หรือ 31 | 100 | 2.76:1 | |

| เอ็นซี 46-65 (4 ไอเอฟ) | 6-1/2 | 2-13 /59 | 30 หรือ 31 | 93 | 3.05:1 | |

| เอ็นซี 46-67 (4 ไอเอฟ) | 6-3 /4 | 2-1/4 | 30 หรือ 31 | 109 | 3.18:1 | |

| เอ็นซี 50-70 (4-1/2 ถ้า) | 7 | 2-1/4 | 30 หรือ 31 | 118 | 2.54:1 | |

| เอ็นซี 50-70 (4-1/2 ถ้า) | 7 | 2-13 /59 | 30 หรือ 31 | 111 | 2.73:1 | |

| เอ็นซี 50-72 (4-1/2 ถ้า) | 7-1/4 | 2-13 /59 | 30 หรือ 31 | 120 | 3.12:1 | |

| นอร์ทแคโรไลนา 56-77 | 7-3 /4 | 2-13 /59 | 30 หรือ 31 | 140 | 2.70:1 | |

| นอร์ทแคโรไลนา 56-80 | 8 | 2-13 /59 | 30 หรือ 31 | 151 | 3.02:1 | |

| ทะเบียน API 6-5/8 | 8-1/4 | 2-13 /59 | 30 หรือ 31 | 162 | 2.93:1 | |

| นอร์ทแคโรไลนา 61-90 | 9 | 2-13 /59 | 30 หรือ 31 | 196 | 3.17:1 | |

| ทะเบียน API 7-5/8 | 9-1/2 | 3 | 30 หรือ 31 | 217 | 2.81:1 | |

| นอร์ทแคโรไลนา 70-97 | 9-3 /4 | 3 | 30 หรือ 31 | 230 | 2.57:1 | |

| เอ็นซี 70-100 | 10 | 3 | 30 หรือ 31 | 243 | 2.81:1 | |

| ทะเบียน API 8-5/8 | 11 | 3 | 30 หรือ 31 | 300 | 2.84:1 |

ปลอกคอเจาะแบบไม่มีแม่เหล็ก

| อุณหภูมิห้อง มาตรฐาน ASTM A 370 | ||||||||

| ช่วง OD ปลอกคอเจาะ | นาที. ความแข็งแรงของผลผลิต | นาที. ความต้านแรงดึง | นาที. การยืดตัว% | การทดสอบแรงกระแทก CHARPY V. notch | ||||

| MPa | พีเอสไอ | MPa | พีเอสไอ | เจ (นาที) | ฟุต-ปอนด์ (นาที) | |||

| 2 3/4″ ถึง 3 7/8″ | 827 | 120,000 | 896 | 130,000 | 16 | 81 | 60 | |

| 4″ ถึง 6 7/8″ | 758 | 110,000 | 827 | 120,000 | 18 | |||

| 7″ ถึง 11″ | 689 | 100,000 | 758 | 110,000 | 20 | |||

เจาะเหล็ก พ.อลาร์ส

| อุณหภูมิห้อง ASTM 4145 H ดัดแปลง | ||||||||

| ช่วง OD ปลอกคอเจาะ | นาที. ความแข็งแรงของผลผลิต | นาที. ความต้านแรงดึง | นาที. การยืดตัว% | การทดสอบแรงกระแทก CHARPY V. notch | ความแข็ง (บริเนล) | |||

| MPa | พีเอสไอ | MPa | พีเอสไอ | เจ (นาที) | ฟุต-ปอนด์ (นาที) | เอชบีเอ็น | ||

| 3 1/8″ ถึง 6 7/8″ | 758 | 110,000 | 965 | 140,000 | 13 | 54 | 40 | 285-341 |

| 7″ ถึง 11″ | 689 | 100,000 | 930 | 135,000 | ||||