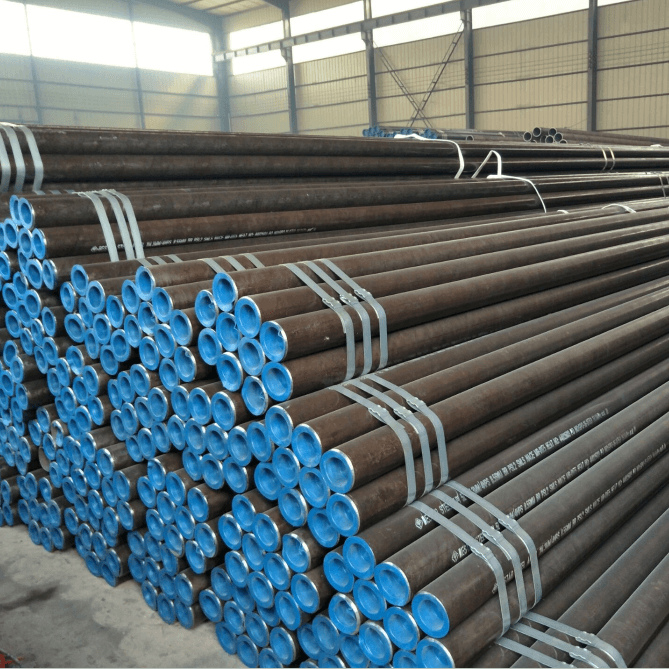

탄소강관은 의도적으로 강철의 합금 성분을 첨가하지 않고 탄소 질량 분율이 2.11% 미만인 것을 주로 말하며, 강철에 함유된 탄소의 수준은 강철의 강도에 영향을 미치는 가장 중요한 요소 중 하나입니다. , 경도가 증가하고 연성, 인성 및 용접성이 감소합니다. 게다가 탄소강 튜브에는 일반적으로 탄소 외에 소량의 규소, 망간, 황, 인도 포함되어 있습니다. 다른 유형의 강철과 비교하여 CS SMLS 파이프는 가장 초기, 저렴한 비용, 광범위한 성능, 가장 많은 양입니다. 공칭 압력 PN ≤ 32.0MPa, 온도 -30-425 ℃ 물, 증기, 공기, 수소, 암모니아, 질소 및 석유 제품 및 기타 매체에 적합합니다. CS 이음매없는 파이프는 현대 산업에서 가장 먼저 가장 많은 양의 기본 재료를 사용합니다. 세계 산업국들은 고강도 저합금강과 합금강 생산량을 늘리기 위해 노력하고 있으며, 품질 향상과 품종 및 용도 확대에도 많은 관심을 기울이고 있습니다. 국가 총 생산량 중 철강 생산량이 차지하는 비중은 대략 80% 수준으로 건물, 교량, 철도, 차량, 선박 및 각종 기계 제조 산업뿐만 아니라 현대 석유화학 산업에서도 널리 사용됩니다. 산업, 해양 개발에도 많이 사용되었습니다.

기준:API 사양 5L, ISO 3183, ASTM A 53M, ASTM A 106M, JIS G 3454, JIS G 3455, JIS G 3456

차원:

SMLS: Φ10.3~1016×1.7~52mm

용접: Φ219~2134×5~52mm

길이:임의 길이, 고정 길이, SRL, DRL

강철 등급:

ASTM A53/ASTM A106: GR A, GR B, GR CASME

ASME A500: GR.A, GR.B, GR.C, GR.D

필요한 테스트:

화학 분석, 기계 테스트, 육안 검사, 인장 테스트, 치수 확인, 굽힘 테스트, 편평 테스트, 충격 테스트, DWT 테스트, NDT 테스트, 수압 테스트, 경도 테스트.

탄소강 튜브의 적용

- 자동차 부문

- 내부 및 외부 건축구조물

- 수도관

- 가스 라인

- 석유 및 가스 산업

- 압력 서비스

- 보일러 및 전력

- 기계

- 가스탱크

- 화학공학

- 해양 및 석유 엔지니어링

탄소강관의 크기

| 외경(mm) | 벽두께(mm) | ||||||||||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 35 | ||

| 73 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 76.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 82.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 88.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 101.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 114.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 127 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 139.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 152.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 159 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 168.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 177.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 193.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 203 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 219.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 244.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 273 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 298.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 323.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 339.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 355.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 457.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 473.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 530 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 558.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 609.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 630 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 기준 | 파이프의 종류 | 수업 | 등급 |

| API 사양 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46, L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q, L485Q X70Q

| ||

| PLS2 사워 환경 | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| 용접 | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

등급:

| 기준 | 등급 |

| ASTM A 53M | 에이, 비 |

| ASTM A 106M | 에이,비,씨 |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

참고: am차트 이외의 등급은 상담을 통해 가능합니다.

화학 성분(%):

| 기준 | 등급 | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

참고: am차트 이외의 등급은 상담을 통해 가능합니다.

열간압연 이음매 없는 강관 제조/생산 공정

압연 라운드 빌렛 – 검사 – 절단 – 가열 – 피어싱 – 신장 – 약간의 장력 감소 – 직선화 – 기업 끝단 절단 – 육안 검사 – NDT – 수압 테스트 – 끝 가공 – 제품 검사 – 도장 및 마킹 – 포장 – 창고

냉간인발(압연) 무봉강관 제조공정

마더파이프(보통 열연파이프용) - 검사 - 어닐링 - 끝단처리(히팅 및 드릴링 홀) - 산세 - 연삭 - 인산화(Annoit) - 냉간 인발(압연) - 탈지 및 세척 - 열처리(용체화 처리) - 교정 – 수압 테스트 – 도장 및 마킹 – 창고 보관

강관의 표면 처리:

송유관의 서비스 수명을 향상시키기 위해 표면 처리는 일반적으로 강관과 부식 방지 코팅의 견고한 결합을 촉진하기 위해 수행됩니다. 일반적인 처리 방법은 청소, 도구 녹 제거, 산세척, 쇼트 블라스팅 녹 제거 네 가지 범주입니다.

1. 강관 표면에 부착된 그리스, 먼지, 윤활제, 유기물 등을 청소하는데, 일반적으로 용제, 유제 등을 사용하여 표면을 청소합니다. 그러나 강관 표면의 녹, 산화피막, 용접슬래그 등은 제거할 수 없으므로 다른 처리방법이 필요하다. 공구 녹 제거 강관 표면 산화물, 녹, 용접 슬래그는 강철 와이어 브러시를 사용하여 표면 처리를 청소하고 광택을 낼 수 있습니다. 공구 녹 제거는 수동 및 전력으로 나눌 수 있으며, 수동 공구 녹 제거는 SA에 도달할 수 있습니다.

2. 수준, 전동 공구 녹 제거는 Sa3 수준에 도달할 수 있습니다. 강관의 표면이 특히 강한 산화 피막으로 부착된 경우, 도구를 사용하여 녹을 제거하는 것이 불가능할 수 있으므로 다른 방법을 모색해야 합니다.

3. 산세 일반적인 산세 방법에는 화학 및 전기 분해가 포함됩니다. 그러나 파이프라인 부식 방지에는 화학적 산세척만 사용됩니다. 화학적 산세척은 강관 표면의 어느 정도 청결도와 거칠기를 달성할 수 있어 후속 앵커 라인에 편리합니다. 일반적으로 재처리 후 샷(모래)으로 사용됩니다.

4. 강관 표면 스프레이 및 대량 방출에 원심력의 작용으로 고속 회전 블레이드, 강철 그릿, 강철 샷, 세그먼트, 광물 및 기타 연마 와이어를 구동하는 고출력 모터에 의한 녹 제거를 위한 쇼트 블라스팅으로 녹을 철저히 제거합니다. , 한편으로는 산화물과 먼지, 반면에 강관은 거친 충격과 마찰력의 작용을 받아 필요한 균일한 거칠기를 달성합니다. 네 가지 처리 방법 중 쇼트 블라스팅과 녹 제거는 파이프 녹 제거에 이상적인 처리 방법입니다. 일반적으로 강관의 내부 표면 처리에는 쇼트 블라스팅과 녹 제거가 주로 사용되고, 강관의 외부 표면 처리에는 쇼트 블라스팅과 녹 제거가 주로 사용됩니다.

스프레이 페인트

방수 포장