Un riduttore per tubi in acciaioè un componente utilizzato nelle tubazioni per ridurne le dimensioni da grande a piccolo in base al diametro interno. In questo caso la lunghezza della riduzione è pari alla media dei diametri dei tubi più piccoli e di quelli più grandi. In questo caso il riduttore può essere utilizzato come ugello. Il riduttore aiuta a soddisfare le tubazioni esistenti di varie dimensioni o il flusso idraulico dei sistemi di tubazioni.

1. Tipi di materiali del riduttore del tubo

Riduttore in acciaio al carbonio vs riduttore in acciaio inossidabile

I riduttori possono essere realizzati in acciaio al carbonio, legato o acciaio inossidabile e molto altro. Rispetto al riduttore in acciaio inossidabile, il riduttore in acciaio al carbonio possiede resistenza alle alte pressioni, maggiore resistenza e resistenza all'usura, ma può essere facilmente corroso.

Standard e gradi dei materiali del riduttore in acciaio al carbonio:

A234 WPB, A420 WPL6, MSS-SP-75 WPHY 42, 46, 52, 56, 60, 65 e 70.

Per riduttore in acciaio inossidabile:

ASTM A403 WP 304, 304L, A403, 316, 316L, 317, 317L, 321, 310 e 904L, ecc.

Per riduttore per tubi in lega:

A234 WP1, WP5, WP9, WP11, WP22, WP91 ecc.

2. Tipi di riduttori

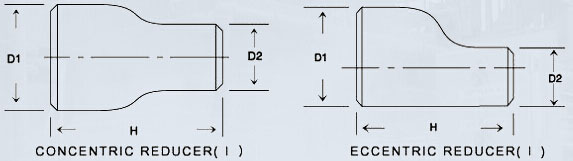

Esistono due tipi di riduttore, riduttore concentrico e riduttore eccentrico.

Riduttore concentrico

Questo riduttore è costituito da raccordi simmetrici e di forma conica che allargano o riducono il diametro equamente rispetto alla linea centrale. Ad esempio, quando il tubo da 1" passa al tubo da ¾", la parte superiore o inferiore del tubo non rimane a livello. È ampiamente utilizzato quando si modifica il diametro singolo o multiplo.

Riduttore eccentrico

Un raccordo di forma conica che riduce o aumenta il diametro, ma non è simmetrico rispetto alla linea centrale. Viene utilizzato nei sistemi di tubazioni per ridurre il diametro di un tubo da una dimensione a una dimensione più grande o piccola.

Differenze tra riduttore concentrico e riduttore eccentrico

I riduttori concentrici sono ampiamente utilizzati mentre i riduttori eccentrici vengono applicati per mantenere il livello del tubo superiore e inferiore. I riduttori eccentrici evitano inoltre l'intrappolamento dell'aria all'interno del tubo e il riduttore concentrico rimuove l'inquinamento acustico.

3. Processo di produzione del riduttore per tubi in acciaio

Esistono processi di produzione versatili per i riduttori. Questi sono costituiti da tubi saldati con il materiale di riempimento richiesto. Tuttavia, i tubi EFW ed ERW non possono utilizzare il riduttore. Per produrre parti forgiate vengono utilizzati diversi tipi di metodi, inclusi processi di formatura a freddo e a caldo. Include il "Metodo del dado esterno".

4. Metodo del diametro esterno

È il metodo più comune per produrre il riduttore per tubi in acciaio. Il tubo viene tagliato e pressato nella matrice esterna mentre un'estremità del tubo viene compressa nella dimensione più piccola. Questo metodo è adatto per la produzione di riduttori di piccole e medie dimensioni.

5. Tipi di connessione del riduttore del tubo

Gamme di diversi tipi di connessione, il riduttore del tubo può essere classificato con riduttore con saldatura a tasca e riduttore con saldatura di testa.

Riduttore per saldatura a presa vs Riduttore per saldatura di testa

Il riduttore per saldatura a tasca chiamato anche inserto per saldatura a tasca, ha tre tipi 1, 2 e 3. Gli standard di produzione sono conformi ad ASME B16.11.

La presa di saldatura resiste a metà della forza della saldatura di testa, quindi viene utilizzata per tubi di piccolo diametro con un diametro pari o inferiore a NPS 2. Butt Weld ha una buona resistenza, poiché è adatto per condotte ad alta pressione e temperatura.

Estremità della riduzione con saldatura di testa piane o smussate, prodotte in conformità con ASME B16.9 e processo di saldatura secondo ASME B16.25.

6. Applicazioni del riduttore per tubi in acciaio

L'utilizzo di un riduttore in acciaio viene effettuato nelle fabbriche chimiche e nelle centrali elettriche. Rende il sistema di tubazioni affidabile e compatto. Salvaguarda il sistema di tubazioni da qualsiasi tipo di impatto negativo o deformazione termica. Quando è sul cerchio di pressione, impedisce qualsiasi tipo di perdita ed è facile da installare. I riduttori rivestiti in nichel o cromo prolungano la vita del prodotto, utile per linee ad alto vapore, e prevengono la corrosione.

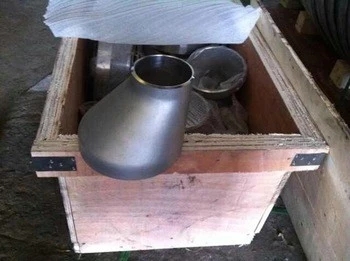

Riduttore per tubi, raccordi per riduttori

I riduttori per tubi in acciaio disponibili sono di tipo concentrico ed eccentrico. I riduttori per tubi sono componenti adatti nelle tubazioni che riducono le dimensioni dei tubi da fori grandi a piccoli. Le estremità di ingresso e uscita dei riduttori per tubi in acciaio e dei riduttori per tubi in lega si allineano su una linea centrale comune.

I riduttori possono essere realizzati in acciaio al carbonio, legato o acciaio inossidabile e molto altro. Rispetto al riduttore in acciaio inossidabile, il riduttore in acciaio al carbonio possiede resistenza alle alte pressioni, maggiore resistenza e resistenza all'usura, ma può essere facilmente corroso.

Standard e gradi dei materiali del riduttore in acciaio al carbonio:

A234 WPB, A420 WPL6, MSS-SP-75 WPHY 42, 46, 52, 56, 60, 65 e 70.

Per riduttore in acciaio inossidabile:

ASTM A403 WP 304, 304L, A403, 316, 316L, 317, 317L, 321, 310 e 904L, ecc.

Per riduttore per tubi in lega:

A234 WP1, WP5, WP9, WP11, WP22, WP91 ecc.

Oliatura leggera, pittura nera