-

API 5L/ASTM A106 GR.B, Seamless Carbon Steel Pipe

API 5L/ASTM A106 GR.B, Seamless Carbon Steel Pipe DN OD(mm) SCH40(6m/5.8m) SCH80(6m/5.8m) SCH160(6m/5.8m) WT FOB WT FOB WT FOB (mm) USD/TON (mm) USD/TON (mm) USD/TON 1/4” 13.7 2.24 10.00 3.02 10.00 / / 3/8” 17.1 2.31 10.00 3.2 10.00 / / 1/2” 21.3 2.77 10.00 3.73 10.00 4.78...Read more -

API 5L GR.B/ASTM A53 GR.B, CARBON STEEL, LSAW STEEL PIPE

API 5L GR.B/ASTM A53 GR.B, CARBON STEEL, LSAW STEEL PIPE FOB TIANJIN Outside Diameter (mm) USD/TON 406 457 508 609.6 711.1 762 812 863.6 Wall 8 772 772 779 765 765 765 765 765 Thickness 9.53 736 758 765 743 743 743 743 743 (mm) 10 736 722 729 743 743 743...Read more -

API 5L/ASTM A53 GR.B (SMALL DIAMETER ERW STEEL PIPE)

API 5L/ASTM A53 GR.B (Small Diameter ERW Steel Pipe) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN (mm) (mm) USD/TON (mm) (mm) USD/TON 33.4 (1″) 2.1-2.4 627.64 Φ133 3.0-5.75 603.05 2.5-3.25 607.39 6.0-7.75 613.17 3....Read more -

API 5L/ASTM A53 GR.B (Hot Rolled ERW Steel Pipe)

API 5L/ASTM A53 GR.B (Hot Rolled ERW Steel Pipe) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN (mm) (mm) USD/TON (mm) (mm) USD/TON 219、245 5.0-11.75 613.17 462 5.75-11.75 646.06 273 5.0-11.75 613.17 12.5-13.75 653.59 12.5-13.75 6...Read more -

API 5L GR.B/ASTM A53 GR.B (HOT EXPANDED ERW STEEL PIPE)

API 5L GR.B/ASTM A53 GR.B (HOT EXPANDED ERW STEEL PIPE) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN (mm) (mm) USD/TON (mm) (mm) USD/TON 245, 273 5.0-9.28 632.44 450, 457, 508, 530 6.5-11.98 656.85 9.45-9.98 635.39 12.0-14.5 664...Read more -

There are three ways to connect galvanized steel pipes

1. Connection by rolling groove Crack of rolling groove weld: ① Grind the inner wall weld ribs of the grooved part of the steel pipe mouth to reduce the rolling groove resistance; ② Adjust the axis of the steel pipe and the rolling groove equipment, and require the steel pipe and the rolling groo...Read more -

Commonly used heat treatment processes for steel pipes, heating and cooling specifications for various heat treatment processes

1. Quenching (1) Carbon and alloy structural steel pipes ① For carbon steel parts and some alloy steel parts with complex shapes, water, and oil are used for cooling. ② This section is used for carbon steel parts and some alloy steel parts with complex shapes. (2)Chromium stainless steel pipes an...Read more -

Exploring the manufacturing and application of DN1400 steel pipe

DN1400 steel pipe, as a giant-level steel pipe, plays an important role in the field of modern engineering. Its diameter reaches 1400 mm, carries important conveying and supporting functions, and is widely used in various engineering projects. Let us explore the manufacturing process, characteris...Read more -

What are the process flows of hot rolled steel pipes

Hot rolled steel pipe, as the name suggests, is a steel pipe rolled at high temperature. Its production process can be said to be an epic of metal deformation, full of heat and deformation. The following is a simple description of the hot-rolled steel pipe production process: Everything starts wi...Read more -

5 commonly used heat treatment processes for seamless steel pipes

What are the five commonly used heat treatment processes for seamless steel pipes? There are many varieties of seamless steel pipes, and the steel grades (species) used are also different. The chemical composition of steel pipes of the same type may also have certain differences, but after heat t...Read more -

Detail of industrial precision bright steel pipe

Precision bright steel pipe is a high-precision steel pipe material that is processed by precision drawing or cold rolling of ordinary seamless steel pipe (or diameter-reduced welded steel pipe). Because there is no oxide layer on the inner and outer walls of precision bright steel pipes, they ca...Read more -

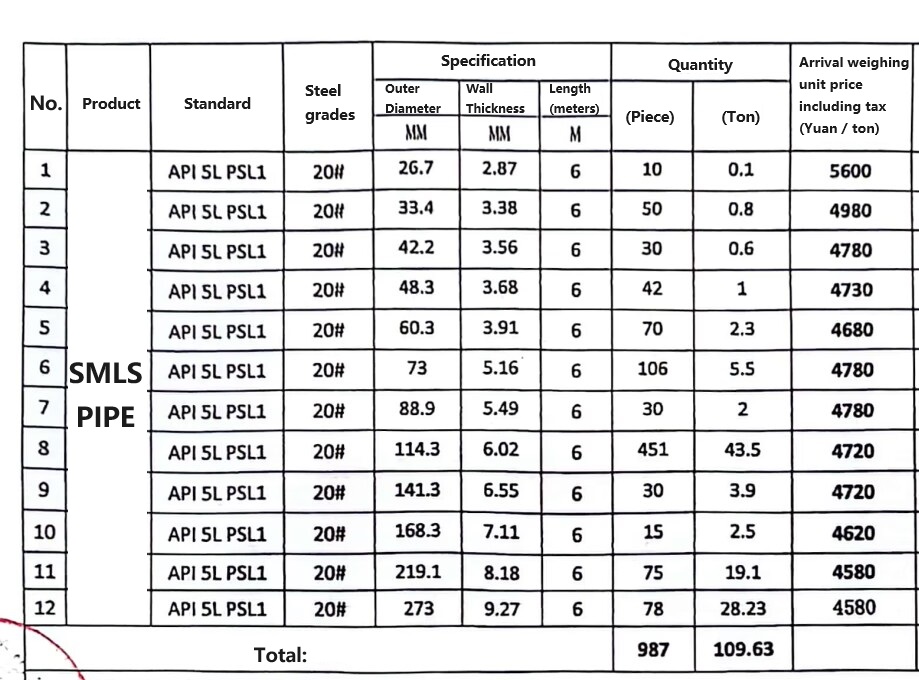

API 5L PSL1, SEAMLESS STEEL PIPE PRICE LIST

Read more