-

Defects of hot dip galvanized pipe

Defects of hot dip galvanized pipe In the production process and packaging process of hot dip galvanized, the appearance of hot dip galvanized steel strip and steel plate may occur following defects. The excess liquid zinc from galvanized pot on the strip surface, which excess liquid zinc air kni...Read more -

Consequences of seamless steel pipe friction

In the plastic deformation process of seamless steel pipe, the presence of friction is very negative and harmful consequences arising mainly as follows: 1) the presence of the steel pipe to change the distribution of frictional force when deformed, thereby causing the uneven distribution of stres...Read more -

Classfication of seamless pipe

According to the manufacturing process,seamless pipe can be divided into hot-rolled seamless steel tubes and cold-drawn seamless steel pipe two kinds. Cold drawn tube is also divided into circular pipe and shaped pipe. Seamless steel tubes is divided into the following categories because of diffe...Read more -

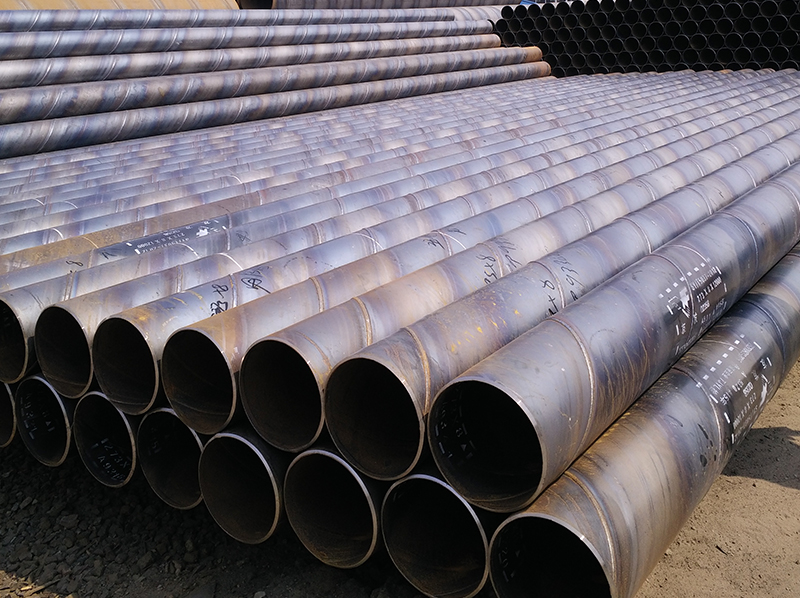

Constructive Spiral welded steel pipe

Spiral-welded steel pipe through 144 inches (3600 mm), in accordance with the requirements of AWWA C200, ASTM A139, and ASTM A252 Wall thicknesses through one inch Allowable yield strengths up to 70,000 psi Fittings and fabrications to support nearly unlimited joint or body configuration Field-we...Read more -

EFW pipe vs ERW pipe

Electric Fusion Welding(EFW steel pipe) refers to an electron beam welding, the use of high-speed movement of the electron beam directed impact kinetic energy is converted to heat the workpiece so that the workpiece leaving the melt, the formation of the weld. It is mainly used for welding dissim...Read more -

Coal tar epoxy pipe storage methods

1. The principle requires coal tar epoxy pipe stacking under palletizing firm to ensure the safety of the premise, according to achieve varieties, specifications palletizing, different varieties of materials to palletizing respectively, to prevent muddy and mutual erosion; 2.Banned in coal tar ep...Read more -

Characteristics of round billet continuous casting

Round billet used in the production of seamless steel tubes of different caliber. Seamless steel pipe production round billet while rotating propulsion and perforation, round billet is inclined to rely on two rollers to rotate the rod core end plug. The inner surface of the inner wall is perforat...Read more -

Application of steel pipes in concrete structures

It is often seen that it is used in water-cooled steel pipe structural systems. This is to use a specially designed structural system to make the water containing antirust and antifreeze constitute a circulation, and reduce the temperature to improve the refractory of the steel. This closed chann...Read more -

Causes of pits on the surface of seamless steel pipes and treatment methods

Continuous pits on the surface of seamless steel pipe cause: 1. Heavy wear on the rolls and grooves 2. The roll is not cooled well, and the surface is sticky steel 3.The surface of the conveying roller table is not smooth 4.The high temperature heating time of the abandoned tube in the heating is...Read more -

Production steps of spiral steel pipe

How to produce a variety of spiral steel pipes from a piece of steel? Today I will introduce to you, the steps in the production of spiral steel pipes are briefly introduced. (1) Various inspections of raw materials. Raw materials generally refer to strip coils, welding wires, fluxes, etc. Before...Read more -

How does the weld burr of the anti-corrosion spiral steel pipe form and eliminate

How does the weld burr of the anti-corrosion spiral steel pipe form and eliminate The technology of removing internal burrs is difficult. Because the special device for removing internal burrs is inside the steel pipe, the working environment is very poor, invisible and inaccessible. It is affect...Read more -

Why is galvanized steel pipe corrosion resistant?

Galvanized steel pipe is made by reacting zinc in a molten metal state with an iron substrate to generate an alloy layer, thereby combining the substrate and the plating layer. In the use of galvanizing technology, hot-dip galvanizing of galvanized steel pipe is to pickle the steel pipe first. In...Read more