-

There are spiral steel annealing process in use, mainly in the following three ways

1, To stress annealing Stress relief annealing, also known as low-temperature annealing (or tempering), which is mainly used to eliminate annealing casting, forging, welding, hot-rolled, cold-drawn pieces residual stress and the like. If not eliminate these stresses will cause the steel after a c...Read more -

Surface Treatment of Precision Steel Pipe

Surface treatment of precision steel pipe is by changing the precision steel surface tissue heat treatment to alter one surface properties. Surface hardening eleven surface structure change, without changing the chemical composition of the surface heat treatment. It can be used high-frequency, in...Read more -

Defects of Welded Steel Pipe

Welded steel pipe production process is a steel sheet, strip, and other various molding methods using the straight press roll or helical direction curling into a desired cross-sectional shape, and then by means of heat, pressure, different methods of welding weld together to obtain steel. Therefo...Read more -

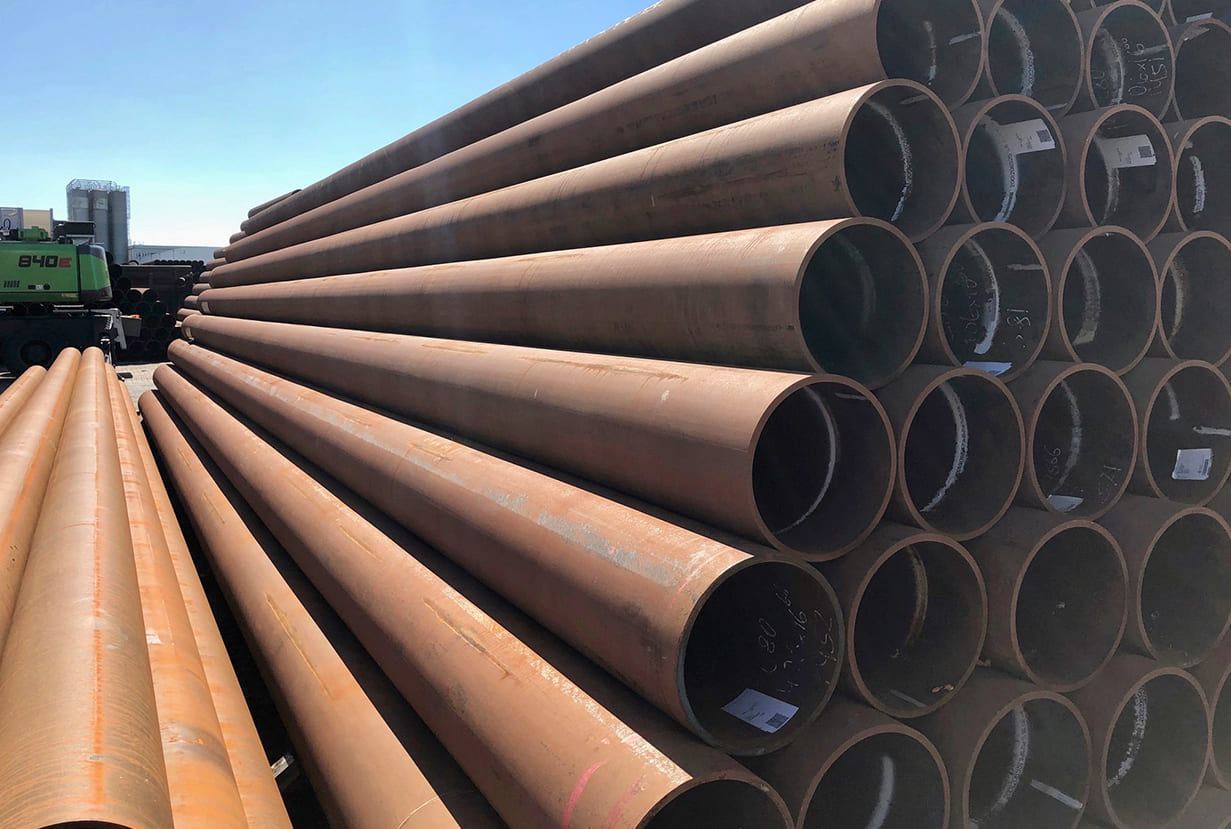

Storage Conditions of Seamless Steel Pipe

1) Steel storage site or warehouse, should be selected in the clean, smooth drainage area, away from harmful gases or dust factories and mines. Presence on the ground to clear all the weeds and debris, keeping a clean steel; 2) In a warehouse not with acid, alkali, salt, cement, steel and other a...Read more -

Puncher of Seamless Steel Pipe

Production of hot-rolled seamless tube perforation is the most important step of deformation, its mission is to wear a solid tube rolled into a hollow tube. According to the structure and deformation characteristics piercing process of piercing machine can be divided into conventional perforating...Read more -

Features and benefits of seamless steel pipe

Features and benefits of seamless steel pipe 1. High precision machining saves wear and tear when the user quantity. 2. Specifications, wide range of applications. 3. Cold rolled finished high accuracy, good surface quality, good straightness. 4. The inner diameter of the pipe can be made hexagon...Read more -

Embrittlement of Precision Steel Pipe

Brittle tempering temperature range based on precision tubes can be divided into low and high temperature temper brittleness temper brittleness. After tempering brittleness precision tube alloy steel quenched martensite at a temperature range of 250 ~ 400 ℃ tempered steel embrittlement which a br...Read more -

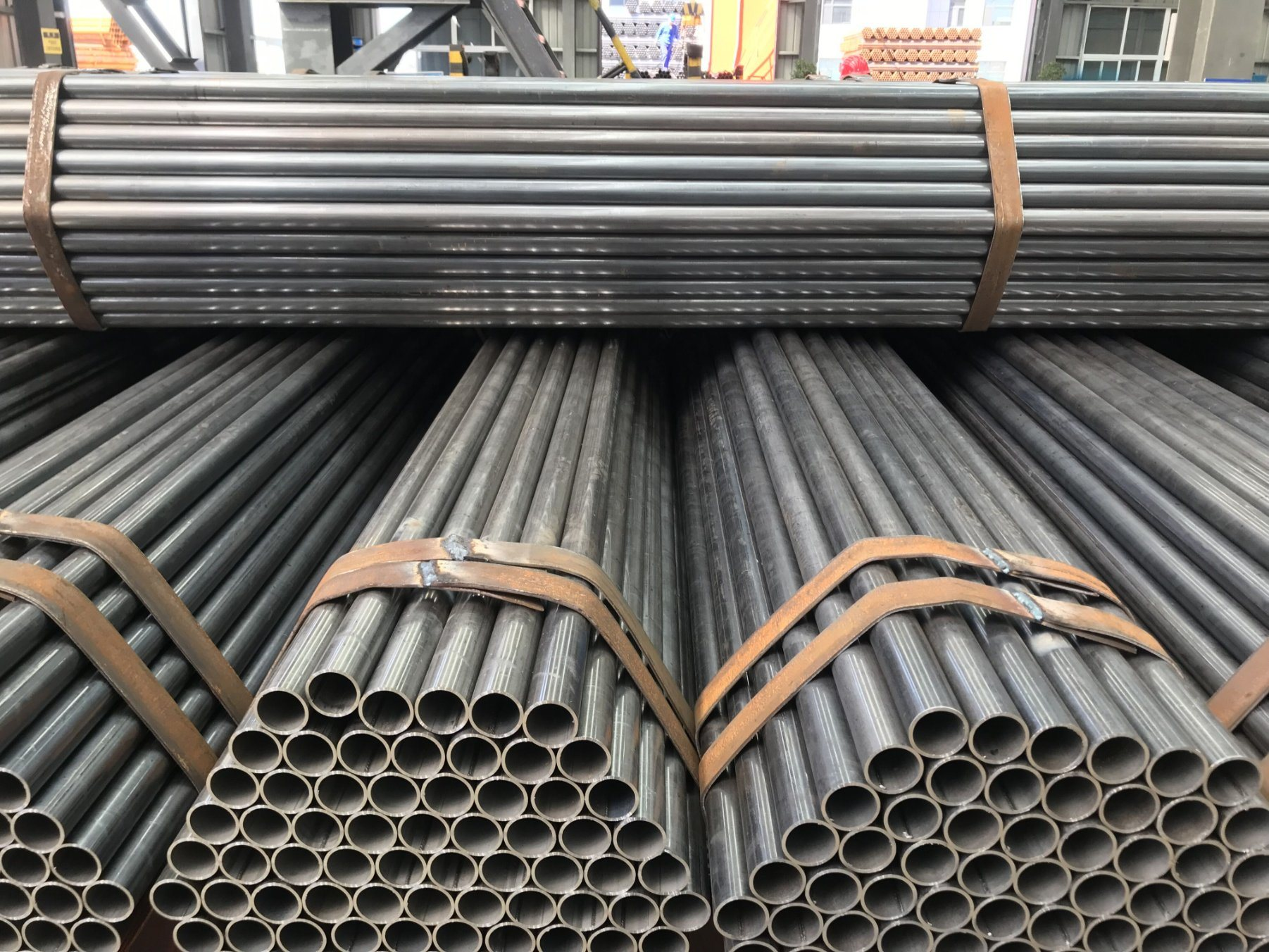

Applications Category of Finishing Seamless Steel Tubes

Finishing seamless steel tubes extensive assortment of applications: classification of finishing seamless steel pipe is widely applied: 1, Finishing with seamless steel structure seamless steel tubes for general structural and mechanical structure. 2, Transmission fluid with seamless steel pipe f...Read more -

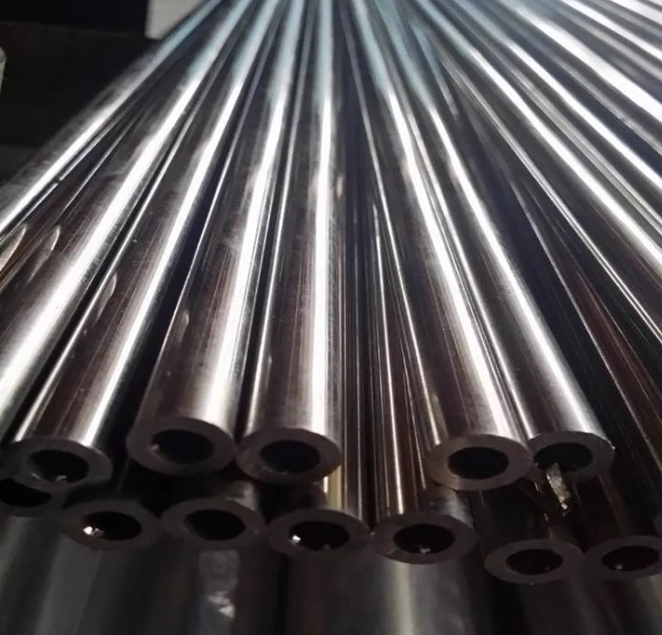

Precision Seamless Steel Tube

Precision seamless steel pipe is a cold drawn or hot-rolled after treatment of a high-precision steel pipe. As the precision seamless steel pipe inside and outside the wall of non-oxidized layer of precision seamless steel pipe, to withstand high pressure without leakage, high precision, high fin...Read more -

Rupture Phenomenon of Cold Drawn Seamless Steel Pipe

When seamless steel tubes are cold drawn, hot rolled tube defects such as cracks or the presence of high-precision drawing fuel tank is made after the fracture occurred in the course, almost no plastic deformation occurred, generally are brittle fracture. Brittle fracture is caused by a variety o...Read more -

Weld Appearance Requirements of Pressure Pipe

Before the pressure pipeline nondestructive testing, visual inspection of welds shall comply with the requirements. Pressure pipe weld appearance and surface quality of welded joints general requirements are as follows: welding should look good shape, width of each side groove edge 2mm overshadow...Read more -

Quenching Method of Steel Pipe Deformation and Crack

Austempering is to reduce the deformation of steel pipe and an effective method of quenching crack Jian, but how to properly use the process method should be based on reasonable seamless steel pipe material, size, hardness and toughness, deformation requirements, and specific working conditions t...Read more