-

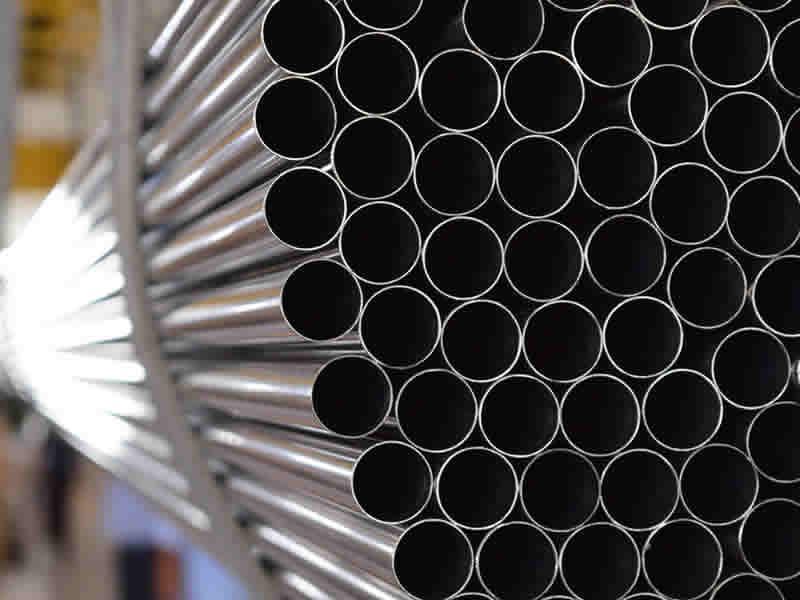

Classification of welded pipe

According to different welding methods, it can be divided into arc welding, high-frequency or low-frequency resistance welded pipe, gas welded pipe, furnace welded pipe, Bondi pipe, etc. Welded steel pipe: used in oil drilling and production and machinery manufacturing. Furnace welded pipe: it ca...Read more -

Annealing process of seamless pipe

After the final heat treatment, the microstructure of 12Cr1MoVG alloy seamless tube blank has changed into Tempered Microstructure with martensite orientation, and has good strength and plastic toughness. In some areas, there are some “invisible” grain boundaries around the adjacent t...Read more -

Corrosion resistance analysis of alloy steel pipe

The chemical production with salt as raw material will produce strongly corrosive hydrochloric acid along with its process. Therefore, corresponding measures should be taken in the design of chemical equipment and pipelines. Shenyang Liaozhong chemical plant uses sandviksaf2205 steel for relevant...Read more -

Automatic ultrasonic flaw detection process flow and program control scheme of submerged arc straight seam welded steel pipe

The main procedures of LSAW longitudinal welded steel pipe automatic ultrasonic testing process flow include: system startup, welded pipe feeding, welded pipe transmission, welded pipe rotation, welded pipe clamping and positioning, weld flaw detection, spray marking, welded pipe clamp loosening...Read more -

Production technology of hot rolled seamless steel pipe

Seamless steel pipe plays an important role in urban infrastructure and the production, processing and manufacturing of mechanical products. Therefore, driven by the market, its production and processing technology has developed rapidly. The production process of hot rolled seamless steel pipe is...Read more -

Extrusion technology of alloy seamless pipe

The early development process of extrusion technology is from soft metal to hard metal, from manual to mechanized, semi continuous, and further to continuous. With the continuous development of new engineering materials and the pursuit of high material utilization, modern extrusion technology wil...Read more -

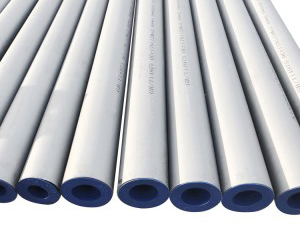

Advantages and disadvantages of stainless steel strip weld pickling welded pipe and polished welded pipe

Advantages and disadvantages of stainless steel strip weld pickling welded pipe and polished welded pipe: 1. The pickled welded pipe with weld has uniform wall thickness and strong bearing pressure. After manual polishing, the wall thickness of raw materials will become thinner, especially...Read more -

Production process and characteristics of hot rolled seamless steel pipe

Hot rolled seamless steel pipe: compared with cold rolling, cold rolling is rolling below the recrystallization temperature, and hot rolling is rolling above the recrystallization temperature. Advantages: it can destroy the casting structure of ingot, refine the grain of steel and eliminat...Read more -

What is the purpose of 304 stainless steel pipe?

304 stainless steel pipe is a kind of high alloy steel which can resist corrosion in air or chemical corrosion medium. 304 stainless steel pipe is a kind of steel with beautiful surface and good corrosion resistance, which gives full play to the inherent surface properties of stainless steel with...Read more -

Standard for steel grade of petroleum casing

The steel grades of casing include H40, J55, K55, M65, N80, L80, C90, C95, T95, P110, q125 and V150. H40 is a low-grade steel, which is rarely used in the market. The yield strength of J55 and K55 belongs to the same level. The difference between them is that the tensile strength of K55 is...Read more -

Production method of P91 alloy pipe

1. It is divided into P91 alloy pipe hot rolled pipe, P91 alloy pipe cold rolled pipe, P91 alloy pipe cold drawn pipe, P91 alloy pipe extruded pipe, etc. The solid pipe blank is checked and cleaned of surface defects, cut into the required length, sent to the heating furnace for heating and perfo...Read more -

How to identify stainless steel pipe?

1、Magnetic test Magnetic test is the simplest method to distinguish annealed austenitic stainless steel from ferritic stainless steel. Austenitic stainless steel is non-magnetic steel, but it will have slight magnetism after cold working under high pressure; Pure chromium steel and low alloy ste...Read more