-

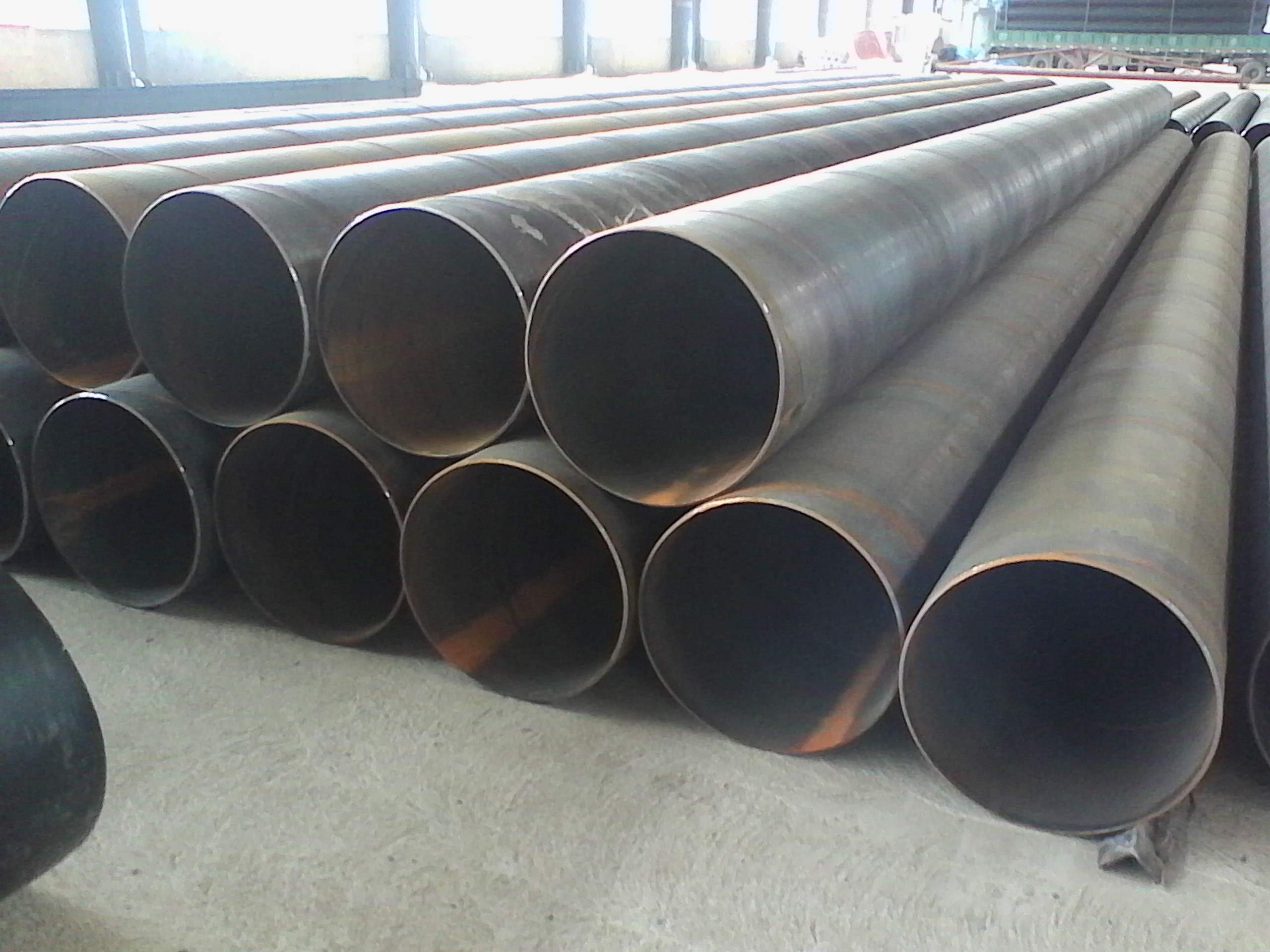

Large diameter spiral pipe submerged arc welding process

Welding way of spiral pipe is submerged arc welding; molding process, before tilting intermittent production; unit speed, 0.5–3m / min; welding speed, 0.5–3m / min. Units from uncoiling machine, straightening machine, on the device, hydraulic shears, milling welder, disc cutter, milli...Read more -

Inspecting of seamless steel pipe

Ultrasonic testing for steel quality inspection includes detection of defects in ultrasonic testing purposes and to measure the relevant dimensions for the purpose of ultrasound measurements. The former is widely used, both automated testing, there is manual testing; while the latter applications...Read more -

High pressure boiler tube pickling and phosphating process

High pressure boiler tube chemical degreasing 1) chemical degreasing take the way of tank soak, in addition to the oil sump with steel production, the inner wall of the shop PVC or polyethylene. 2) Use of nitric acid of 12 to 15% (by volume) chemical degreasing treatment, a temperature of 40 ° ...Read more -

ERW Steel Pipe and LSAW Steel Pipe

ERW steel pipe stand for Electric Resistance welded steel pipe. ERW steel pipes are used in various engineering purposes and Agricultural purposes. The standard of ERW structural steel pipes are limit, only high-quality, low-carbon steel is used. High performances of ERW steel pipes bring many ad...Read more -

Electrode for resistance welding

Resistance welding spot welding, seam welding, projection welding and butt welding all need to use the consumable electrode, although the shape of the electrodes are not identical, however, which is used to weld a transmission welding current and welding stress in the welding process. Some weldin...Read more -

Identification of fake spiral steel pipe

Identification of fake spiral steel pipe 1. Inferior spiral pipe prone folding. Folding is formed on the surface of a variety of spiral steel fold, this defect is often throughout the product’s portrait. The reason is due to the poor quality manufacturers folding pursuit of high efficiency,...Read more -

HDPE lined steel pipe

HDPE lined steel pipe slightly larger than the outer diameter of tube technology is the main channel diameter HDPE liner, after necking, making cross-section smaller than the cross-sectional area of the main channel, in the role of traction quickly insert the main channel. Rely on their memory ch...Read more -

Galvanized steel pipe welding technology

Galvanized steel welding characteristics: Galvanized steel pipe is generally in the low-carbon steel outer layer of zinc-plated, galvanized layer is generally in the 20um thick. Melting point of zinc in 419 °C, bp 908 °C or so. In welding, the zinc melted into the liquid floating on the surface o...Read more -

Features of high-strength structural steel

Due to the high-strength structural steel pipe is formed of high strength steel having a large moment of inertia and flexural modulus, in particular on the requirements of the application due to the need for cold bending processing after the pre-punched, the material would be formed on the surfac...Read more -

Galvanized Seamless Pipe

Classification of galvanized seamless pipe Galvanized seamless pipe is divided into cold-plated steel seamless pipe and hot dip seamless pipe. Hot dip seamless pipe The Redu seamless pipe is to make the molten metal and iron substrate reaction, the alloy layer, so that the substrate and coating c...Read more -

ERW pipe welding defects

ERW pipe is the fastest and most efficient tube method, but when produced, there are a variety of high frequency tube welding defects. Analysis of the frequency of inclusions in steel production, the pre-arc fusion inadequate inadequate edge fusion, central fusion deficiencies, stick welding, cas...Read more -

API 5L Linepipe spec

1 Scope 1.1 This specification covers sesamless and welded steel line pipe. It includes standard-weight and extra-strong threaded line pipe. It includes standard-weight and extra-strong threaded line pipe; and standard-weight plain-end,regular-weight plain-end, special plain-end, extra-strong pla...Read more