-

Performance, Production, and Application of Q355B Straight Seam Welded Steel Pipe in the Industrial Sector

First, Material Properties and Standards of Q355B Straight Seam Welded Steel Pipe. Q355B straight seam welded steel pipe uses low-alloy high-strength steel Q355B as its base material. Its chemical composition conforms to GB/T 1591-2018 standard, with a carbon equivalent (Ceq) controlled below 0.4...Read more -

High Strength and Excellent Sealing Performance of API 5LX46QH Seamless Steel Pipe

API 5LX46QH seamless steel pipe is a high-quality oil and gas transportation pipeline widely used in oil, natural gas, chemical, power, and heating industries. Its seamless design ensures the pipeline’s strength and sealing performance, maintaining stable performance even in harsh environme...Read more -

Why are A53 steel pipes commonly used in industrial projects

A53 steel pipe, as a common steel pipe material, is widely used in various fields. From construction to industry, from municipal engineering to petrochemicals, A53 steel pipe plays an important role. 1. Introduction to A53 Steel Pipe A53 steel pipe is a type of carbon steel pipe, classified into ...Read more -

How Much Do You Know About the Characteristics and Applications of Common Q345B Seamless Steel Pipes

Q345B seamless steel pipe, as one of the most important materials in the steel industry, bears crucial structural functions. Q345B seamless steel pipe is a high-quality steel product with the following characteristics: 1. Excellent Mechanical Properties: Q345B steel has high strength and good tou...Read more -

Geometric Characteristics of Large-Diameter Steel Pipe Cross-Sections

(1) Its joint connections are suitable for direct welding, eliminating the need for gusset plates or other connectors, saving both labor and materials. (2) When necessary, concrete can be poured inside the large-diameter steel pipe to form composite components. (3) Large-diameter steel pipe cross...Read more -

Precautions for Welding Commonly Used Industrial Spiral Steel Pipes

Welding and cutting of spiral steel pipe structures are unavoidable in applications. Due to the inherent characteristics of spiral steel pipes, their welding and cutting have unique characteristics compared to ordinary carbon steel, making them more prone to various defects in the weld joints and...Read more -

Analysis of the Development and Application of Anti-corrosion Painting of Straight Seam Steel Pipes in Industrial Projects

The performance and function of unpainted straight seam steel pipes in specific applications fully demonstrate their operational contribution and usage performance. After painting, with white lettering sprayed on, the straight seam steel pipes also look very neat and beautiful. Currently, pipe fi...Read more -

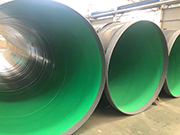

Details Regarding the Composition, Construction, and Storage of Epoxy Resin Anti-corrosion Steel Pipes

First, Composition of Epoxy Resin Anti-corrosion Steel Pipes. 1. Steel Pipes: Seamless steel pipes, straight seam steel pipes, spiral steel pipes, and various other steel pipes. 2. Epoxy Resin Coating: This product is a two-component, high-solids coating with epoxy resin as the main agent. It con...Read more -

Practical Advantages and Diameter Expansion Technology of Industrial Straight Seam Steel Pipes

In a sense, straight seam steel pipe is a type of steel pipe welding process that contrasts with spiral steel pipe. Straight seam steel pipe welding is relatively simple and cost-effective, achieving high production efficiency, making it quite common in the market. As a widely used product, what ...Read more -

A Comprehensive Guide to Welding Processes for Industrial Stainless Steel Pipes

Advances in materials processing have brought unique opportunities to the stainless steel pipe manufacturing industry. Typical applications include exhaust pipes, fuel lines, fuel injectors, and other components. In the production of stainless steel pipes, a flat steel strip is first formed, and ...Read more -

Surface Treatment of Thick-Walled Straight Seam Steel Pipes in Industrial Projects

The uniformity of the steel pipe wall of thick-walled straight seam steel pipes directly affects the quality of the subsequently processed parts. If the pipe wall uniformity is not controlled, the overall quality of the steel pipe cannot be strictly controlled. Small and medium-sized steel sectio...Read more -

Application Areas of Common Large-Diameter Plastic-Coated Steel Pipes

Large-diameter plastic-coated steel pipes primarily use spiral steel pipes or seamless steel pipes as the base material. Straight seam welded pipes are not recommended, as their pressure resistance is generally inferior to spiral steel pipes, and their cost is higher. Therefore, spiral steel pipe...Read more