-

Suggestions on the peeling method of 3PE anti-corrosion coating

1.Improvement of mechanical peeling method of 3PE anti-corrosion coating ① Find or develop better heating equipment to replace the gas cutting torch. The heating equipment should be able to ensure that the spray flame area is large enough to heat the entire coating part to be peeled off at one ti...Read more -

About 3PE anti-corrosion steel pipe coating peeling method

Mechanical peeling method of 3PE anti-corrosion coating At present, in the process of gas pipeline maintenance, the peeling method of 3PE anti-corrosion coating is proposed based on the analysis of the structure and coating process of 3PE anti-corrosion coating [3-4]. The basic idea of peeling ...Read more -

Application of Polyurea Anticorrosion Coating on Pipeline

From the perspective of the coating temperature range, epoxy powder coating and polyurea anti-corrosion coating can be used normally in soil corrosion environments ranging from -30 °C or -25 °C to 100 °C, while the three-layer structure polyethylene The maximum service temperature of the anti-cor...Read more -

Developed high temperature resistant 3pe anticorrosion

With the decline of energy and resource reserves, the pipeline fleet transports more and more gas, asphalt and other low-quality petroleum products, and the construction of marine pipelines is also developing continuously. Development has been uninterrupted. The following is an introduction to so...Read more -

Supply and demand imbalance in Europe’s HRC market stalls

Trading in the European HRC market has been weak recently, and HRC prices are expected to fall further amid sluggish demand. At present, the feasible level of HRC in the European market is around 750-780 euros / ton EXW, but buyers’ purchasing interest is sluggish, and no large-scale transa...Read more -

Application of seamless steel pipe

Seamless steel pipe is a long strip of steel with a hollow section and no joints around it. Steel pipes are divided into two types: hot-rolled and cold-drawn (rolled). Hot-rolled seamless pipes are generally processed on automatic lathes. The outer diameter and wall thickness have high dimensiona...Read more -

Q345B straight seam welded pipe

Q345B straight seam welded pipe is a general name, generally refers to the welded steel pipe of Q345B material. Q represents the yield of this material, and the 345 behind it refers to the yield value of this material. Below 235 is low temperature steel, and above 345 is high temperature steel. T...Read more -

Seamless steel tube root canal wire seamless steel tube

According to different application requirements, seamless steel tube root canals can be divided into steel-aluminum, aluminum-magnesium, aluminum-magnesium-manganese, aluminum-manganese, steel-stainless steel and weldable composite materials. It is a commonly used composite material with strong m...Read more -

Seamless cold drawn square tube

Seamless cold-drawn steel pipes are divided into two types: round and special-shaped according to the shape of the longitudinal section. Special-shaped pipes include rectangle, square, semicircle and various polygons. Cold drawn square tubes are widely used. The general-purpose seamless square tu...Read more -

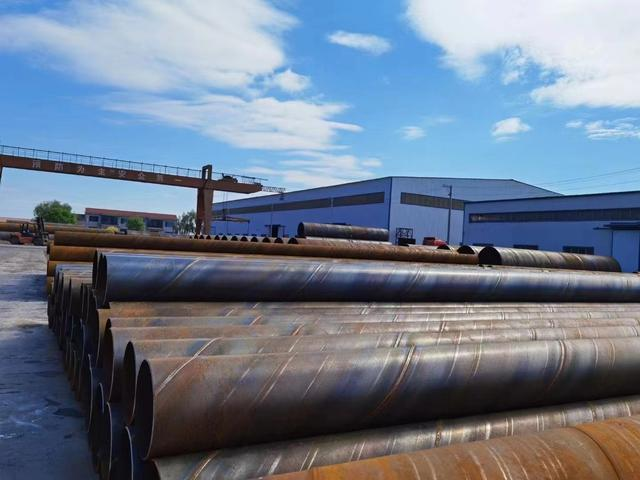

What welding process does the spiral steel pipe factory have?

The spiral steel pipe belongs to the welded pipe, which means that the steel chain or thick steel plate is bent and deformed into a ring, square, etc., and then welded by electric welding, and the surface has a seam. The ingredients selected for welded pipes are thick steel plates or hot-rolled s...Read more -

Classification of welding seam processing of spiral steel pipe welded pipe

When processing spiral steel pipe welded pipe, the processing of weld seam is the essence of spiral welded pipe. The processing classification of spiral steel pipe welded pipe welds is generally divided into three categories: One type of weld: 1. All welds of the fork tube. 2. Longitudinal seam o...Read more -

Elements of porosity in spiral steel pipe welds

The factors that cause porosity in the welding seam of the spiral steel pipe include: dirt, moisture, oxide scale and iron filings in the flux, welding components and covering thickness, the surface quality of the steel plate and the treatment of the edge plate of the steel plate, the welding pro...Read more