-

Difference Between ERW, SSAW, LSAW

Seamless steel pipes are mainly used in oil pipeline and gas pipeline, but seldom used in oil pipelines with long-distance. Most long distance pipeline applied ERW pipes, SSAW pipes and LSAW pipes. Here are comparisons of technological features and performance of these pipes. 1. Electric Resistan...Read more -

Heat treatment process for steel pipe

The quality of heat treatment is directly related to subsequent processing quality and eventually affect the performance and life of the parts, heat treatment is the energy consumption of the machinery industry big polluters. In recent years, with the advancement of science and technology and its...Read more -

Introduction to boiler tube

Boiler tubes is a one of seamless pipe. Manufacturing methods is the same as seamless tube, but it has the stringent requirements for manufacture of steel pipes. According to the temperature level,boiler tube is divided into general boiler tubes and high pressure boiler tube. Production methods: ...Read more -

Big Differences between ERW Steel Pipe and Seamless Pipe

Nowadays, with quick construction of society and rapid development of technology, more and more different kinds of steel pipes are created, such as welded steel pipe, seamless steel pipe, ERW steel pipe and so on, and more and more steel pipes are needed. In the competitive market of steel pipe,...Read more -

Analysis of welded pipe pressure burst

Delivery with steel pipes have been more and more widely used in various industries, and steel pipe multi-buried in damp underground, which has strict requirements for the use of performance of the steel pipe. Existing heat transmission with welded pipe leak in use, check the steel pipe partial s...Read more -

Eddy current testing(ET)

Eddy current testing(ET) use the principle of electromagnetic induction to detect a flaw detection method of the conductive member surface and near-surface defects. Its principle is based on the excitation coil so that the conductive member generates eddy currents, by means of determination of th...Read more -

Difference of ERW and UOE

1: The difference between raw material and production capacity Raw material of ERW steel pipe is hot rolled steel coils, and raw material of UOE pipe is hot rolled steel plate. So the ERW steel tube can realize continuous assembly line work, high production efficiency, production cost is low; A...Read more -

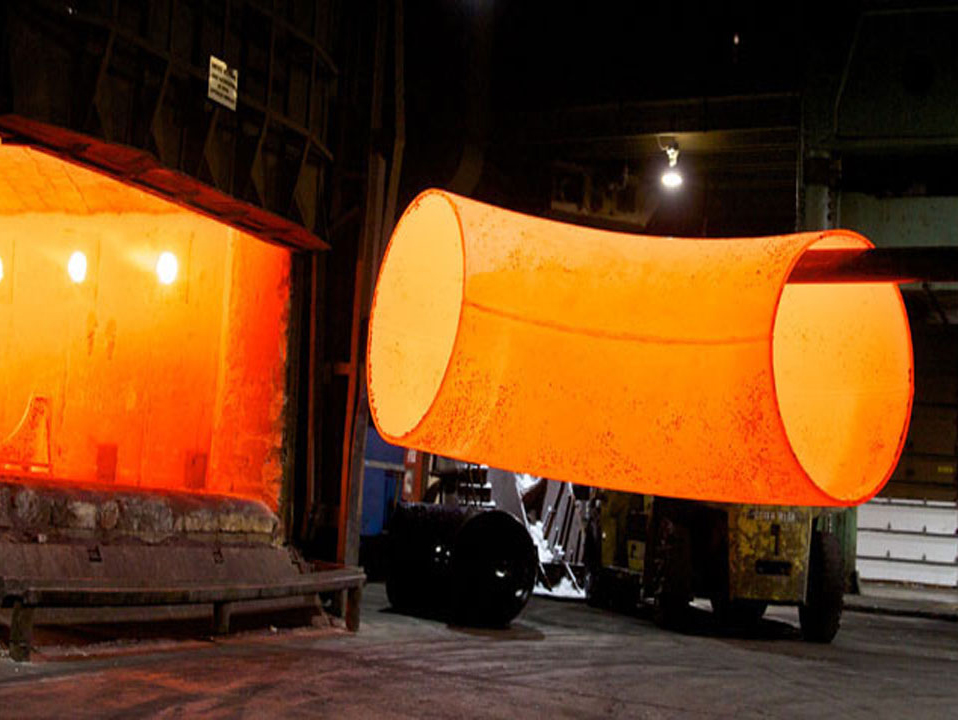

Heat boiler seamless extrusion technology

Hot extrusion is generally carried out for boiler seamless pipe billet, called a composite extrusion. Composite extrusion is currently the best method for producing stainless steel and high nickel alloy seamless tube boilers. It is a large-diameter composite consisting of two or more metal blank ...Read more -

ERW pipe issues and defects

ERW pipe issues and defects is related to raw materials, production methods, process conditions, equipment status and personnel.Product defects that appear in the production process by the above factors and constraints. This product defects can be divided into roughly two categories: one for prod...Read more -

Difference in ERW and SAWL

Difference in ERW and SAWL Straight seam welded steel pipe, according to welding process can be divided into high frequency resistance welding and submerged arc welding, longitudinal submerged arc welded is short for SAWL, high-frequency straight seam resistance welding is short for ERW. High fre...Read more -

The detection of welding steel pipe.

The detection of welding steel pipe. In terms of the physical method: the physical inspection is a way to measure or test with the help of some physical phenomena.The inspection of materials or internal workpiece defects conditions, generally adopts the method of nondestructive flaw detection.The...Read more -

Seamless pipe quench and heat treatment

Surface quench of seamless pipe Some parts in the workpiece in the alternating load, such as torsion and bending under impact load, the surface layer undertake higher stress than the core part. Occasions of friction, the surface layer is worn, some parts of the surface put forward the requirement...Read more